During the NISTM 2025 event, attention focused on a technological proposal that promises to transform the way inspections are carried out in the energy and storage industry. Kimberley Hayes, founder and CEO of Valkim Technologies, presented the PneuBot, a pneumatic robot certified to operate in explosive environments, whose development responds to a critical need: to reduce human risks and optimize the operation of industrial assets.

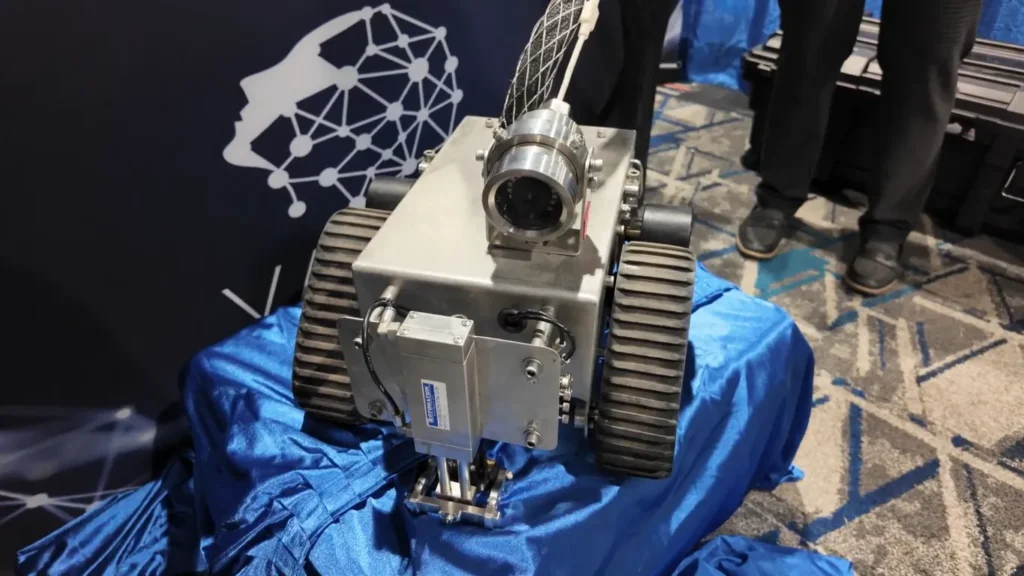

The PneuBot is a fully pneumatic robot with no electrical components, designed to operate in environments where electricity poses a risk of ignition, making it ideal for inspections in areas classified as explosive and minimizing risks while simplifying logistics.

Its main technical features include:

Its entire operation is based on compressed air, which simplifies its use in the field. In addition, Valkim collaborates with specialized manufacturers to integrate previously certified technologies, ensuring compatibility without compromising safety.

The main value of the PneuBot is the protection of human life, as inspections in storage tanks often expose workers to toxic gases and explosion risks, while with this robot, operators remain in safe environments while still obtaining the necessary information.

Hayes' philosophy is that technology does not replace jobs, but rather transforms them by keeping workers out of hazardous areas, opening up new opportunities in areas such as remote operation, maintenance, and data analysis.

In a recent inspection, four hours of operation were saved on an oil tank. With an estimated value of $178,000 per hour, the total savings exceeded $700,000, demonstrating how technology protects lives while preserving asset profitability.

The current business model is based on renting the robot with operation included, ensuring that Valkim provides the necessary expertise for each deployment and avoids logistical problems. In the future, the company plans to implement a certification program that will allow customers to operate the robot independently.

The PneuBot also contributes to reducing environmental risks, as it operates on compressed air and does not generate additional emissions or require polluting energy sources. Its intuitive design allows anyone with basic skid-steer driving skills to operate it in a matter of minutes.

The design philosophy is inspired by the Japanese concept of poka-yoke, which seeks error-proof systems. With unique, color-coded connections, the robot ensures reliable operation even in the hands of users without advanced experience.

For more content on NISTM 2025, visit our LinkedIn profile.

Source: Inspenet.