In the energy industry, safety and reliability are essential, which is why ClampOn's non-intrusive monitoring solutions have become a benchmark within the sector. With more than 30 years of experience, the Norwegian company has established itself as a leader in the manufacture of non-intrusive ultrasonic sensors. Its technology allows measurements and monitoring without the need to penetrate pipes, significantly reducing the operational risks associated with intrusion into critical systems.

Geir Instanes, Vice President of ClampOn, explains that the basis of this technology lies in the use of acoustic sensors to monitor elements such as sand, corrosion, and erosion without having to drill into structures. This approach offers the advantage of taking detailed measurements while maintaining the integrity of the monitored systems.

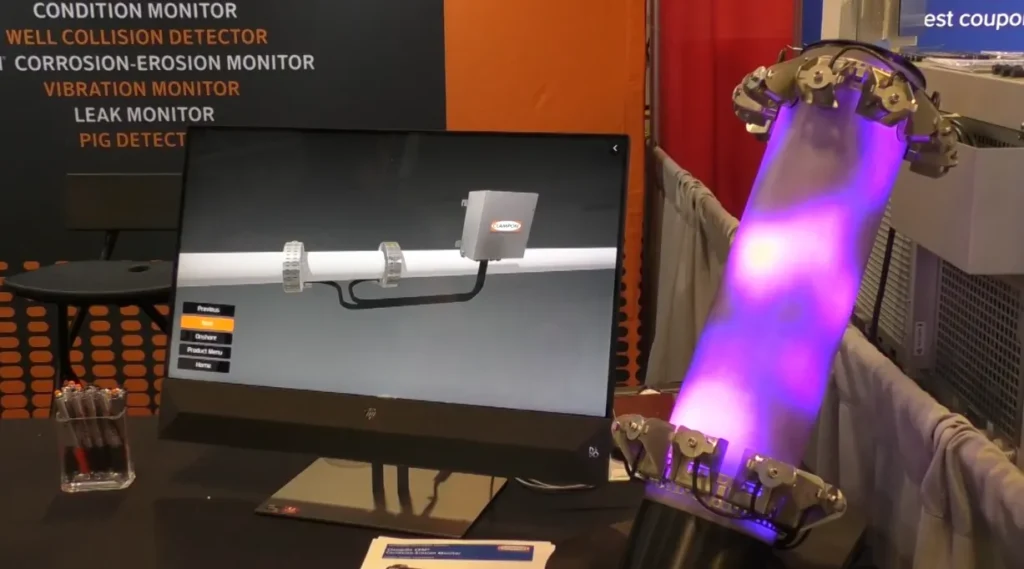

Within ClampOn's portfolio, corrosion and erosion monitoring systems stand out as the most in-demand today. According to Instanes, these devices allow operators to obtain highly sensitive data on the condition of pipelines and other critical components. The main advantage of these systems is their ability to take 360-degree measurements around pipelines, including hard-to-reach areas such as bends.

This precision is vital for companies in the energy sector, where early monitoring of corrosion and erosion can prevent costly and dangerous failures. Thanks to this technology, operators can receive accurate, real-time information, allowing them to make informed decisions that prevent serious long-term damage.

These devices are used in both surface and underwater environments, where conditions are more extreme and variable. In particular, systems designed for underwater operations must guarantee reliability for more than 30 years, as Instanes mentions. The first system the company installed in an underwater environment was in 1999, and it is still in operation today.

This level of durability and reliability is a decisive factor for oil and gas companies, which require systems capable of withstanding harsh conditions for years without compromising performance. In fact, ClampOn does not sell replacement parts, as its sensors are designed to last much longer than traditional competitor products.

The company's technology allows data collected by its sensors to be directly integrated into its customers' SCADA systems, facilitating remote management and predictive maintenance. This allows operators to constantly monitor their assets without the need for physical intervention, thereby optimizing maintenance processes.

Instanes emphasizes that while ClampOn offers comprehensive solutions that include data visualization and analysis, most of its customers prefer to manage their data themselves, explaining that the goal is to offer a complete solution that allows operators to manage their assets independently, without needing to constantly rely on the company.

ClampOn's non-intrusive monitoring solutions represent a true innovation in the energy sector, improving safety, efficiency, and operational reliability. With its ultrasonic sensor technology, the company has proven to be a key partner for the most demanding industries, providing accurate, real-time data that enables more efficient asset management.

For more NISTM 2025 content, visit our YouTube channel and LinkedIn profile.

Source: Inspenet.