Walter H. Weber, founder and president of UTEX Scientific Instruments Inc. shared his vision for the future of AI in industrial inspection, as well as details about his company, during an interview at the PANNDT 2025 conference. Based in Mississauga, Canada, UTEX specializes in the development of software, instrumentation and mechanical systems for industrial automation in sectors such as nuclear, aerospace, oil and gas, combining cutting-edge technology with an international perspective.

UTEX's history dates back to the late 1980s, when they developed pulse receivers and software for Ontario Hydro. They participated in the first edition of PANNDT in 1998, witnessing the transformation of an industry initially dominated by hardware and manual instrumentation to integrated and automated solutions.

Today, the company is a leader in inspection automation, allowing operators to concentrate on critical interpretation tasks while the software takes care of data flow and process execution. Since 1992, its vision has been to reduce manual intervention to increase efficiency, accuracy and standardization of results.

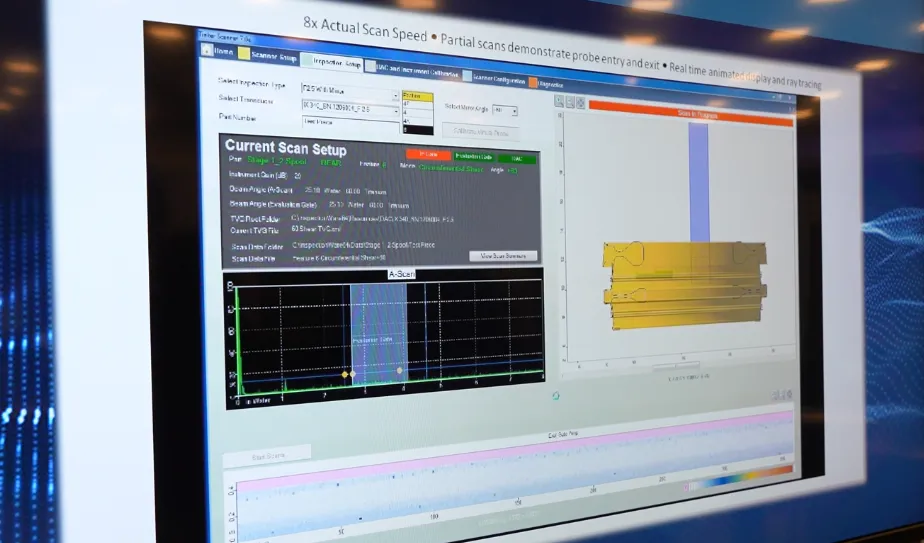

Although the company has mastered techniques such as phased array, its value proposition is based on a much broader vision. Thanks to the InspectionWare platform, together with the flagship IW Evaluate tool, they are able to integrate data from different inspection modalities, such as ultrasound, radiography, terahertz imaging, microwave, eddy current and acoustic emissions.

What is truly distinctive is the company's interoperability, supported by tools such as IW Evaluate, which is capable of reading virtually all file formats in the industry, positioning itself as a universal platform that facilitates data analysis and comparison regardless of the original manufacturer of the acquisition equipment. This reduces technological barriers, promotes standardization and improves operational efficiency.

One of the company's current focuses is the integration of artificial intelligence and machine learning systems to strengthen the automatic evaluation of NDT data. AI is being used to classify internal defects, detect anomalous patterns and assist in making decisions about critical structures.

However, Weber cautions that the use of AI in NDT should be treated with caution, commenting that it is not just about automation, but about ensuring that the AI does not make mistakes or miss faults. That is why UTEX is investing in training representative data sets that reflect real defectologies, industry standards and varying conditions in complex geometries.

In applications such as weld inspection or structural components in aviation or nuclear power, AI must demonstrate equivalence to traditional manual techniques without generating “hallucinations” or false positives. It is a rigorous process that requires continuous validation, multidisciplinary collaboration and transparency in the algorithms.

The systems developed by the company are designed to comply with international standards such as ASME, API, ASTM and particular specifications such as those of Boeing. As a supplier of NDT software, UTEX must incorporate from source the requirements that will allow its partners and integrators to certify their systems in an agile way. This turns the software into an analysis tool with functions, interfaces and modules developed considering the regulatory criteria required in highly demanding sectors.

Weber highlighted the need to strengthen Pan-American ties in the NDT field and the means to achieve this is by increasing their presence in markets such as Argentina and Brazil, taking advantage of the good climate of cooperation that exists between the regions. At the same time, they maintain active ties with Europe and Asia, creating a global collaboration network that allows them to adapt their solutions to diverse regulatory contexts.

UTEX represents a clear convergence between technology, reliability and international vision, in an industry where accuracy saves lives and regulatory compliance is non-negotiable, its commitment to interoperability, automation and artificial intelligence sets a path to follow.

As inspection systems become more complex, AI in industrial inspection not only brings efficiencies, but also a solid foundation for critical industrial decision-making.

For more content on PANNDT 2025, visit our YouTube channel and our LinkedIn profile.

Source: Inspenet.