At ASNT 2025, Jeffrey S. Monks, president of Equipcon, shared details about the company's strategic transformation. With an established track record in providing solutions for nondestructive testing (NDT) solutions, the firm has made a significant shift towards automation, the development of proprietary technology and, above all, its positioning in the aerospace sector.

Equipcon specializes in inspection technologies that detect structural failure in materials without compromising their integrity. In the last two years, the company has started to manufacture its own standard magnetic particle inspection (NPI) and fluorescent penetrant inspection (FPI) systems, incorporating automation and digital integration.

According to Jeffrey Monks, the approach has been to offer modular solutions that adapt to both manual inspections and fully automated processes, gaining with this flexibility the possibility of entering new markets with specific technical needs.

Historically the company had been focused on the automotive industry due to its location in the Midwest of the United States, however, Equipcon has redirected its efforts towards the aerospace industry, as evidenced by a significant change in five years, from representing only 5% of its sales to 45%.

This growth is due to the demand for advanced inspection technologies, especially those capable of operating in demanding production lines and under strict quality standards. Entering into the equation the commitment to develop proprietary technology, which has been a determining factor to respond with agility to these requirements.

With an office already established in Oaxaca, the company advances in its market research and definition of target customers. Faced with the complexity of factors such as customs barriers, tariffs and shipping logistics, Equipcon adopts a gradual and well-structured entry strategy, which allows it to minimize risks and avoid common mistakes in internationalization.

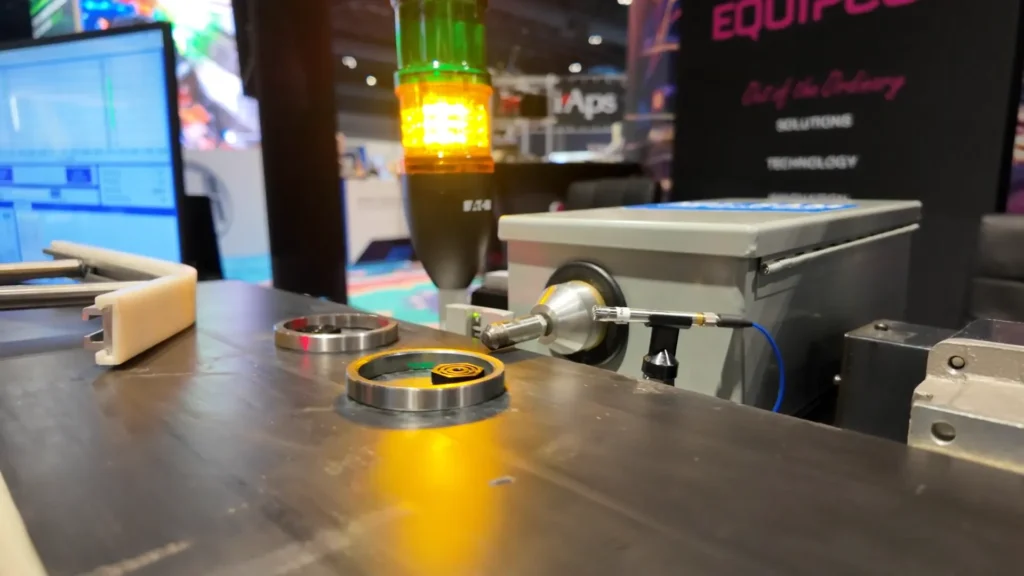

During the interview, Monks demonstrated the operation of acoustic resonance inspection equipment, a technology that can detect structural defects through the vibration frequency of a material.

The principle is simple: if a part is free of flaws, it will resonate clearly upon impact; conversely, if it has cracks, porosities or inclusions, the sound changes. This methodology is particularly effective for powdered metals, additive manufacturing, casting and forging, with an inspection time of just one second per part.

Although Equipcon has not yet integrated artificial intelligence into its systems, Monks recognizes its potential, as AI could mean an advantage in data analysis within NDT, especially in information-rich environments where automated decision making could optimize times and reduce errors.

For the time being, the company is focused on strict rules-based decisions, while keeping a close eye on the opportunities that will arise as the technology takes hold in the sector.

Equipcon is in a process of transformation, evidenced by its commitment to proprietary technology, its adaptability to demanding markets such as aerospace, and its international expansion plan, profiling the company as a relevant option in the world of industrial NDT.

For more content about ASNT 2025, please visit our LinkedIn profile.

Source: Inspenet.