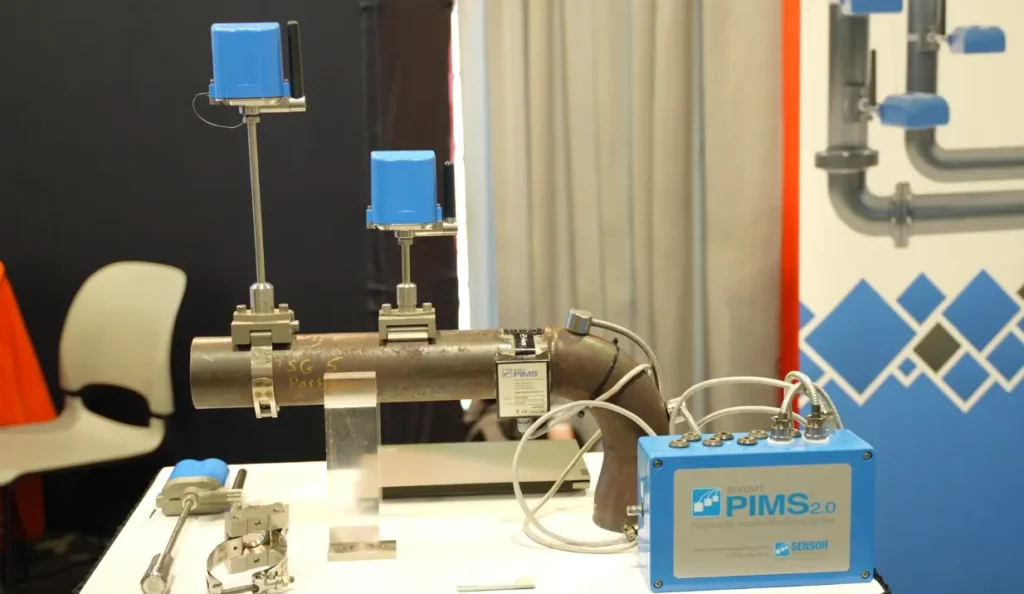

During the AMPP event, Inspenet had the opportunity to speak with Mitchell Gribi , Inspection Solutions Sales Manager at Eddyfi Technologies, who highlighted the role of ultrasonic sensors in refineries and chemical plants for corrosion monitoring. These sensors allow for daily, or even multiple-day, readings to be taken to trace precise patterns in pipe thickness loss exposed to corrosive products.

Gribi explained that this monitoring allows for informed decision-making, process optimization, and, above all, asset lifespan extension. He also stated that when you begin actively monitoring corrosion rates, you can do a lot with that data.

Sensor Networks, the company originally represented by Gribi, was acquired by Eddyfi Technologies approximately two years ago. Based in State College, Pennsylvania, the Sensor Networks team grew from a small local group to a global organization with a presence in more than 110 countries, thanks to Eddyfi's international network.

This integration has strengthened their commercial reach and technical support worldwide, allowing them to reach regions like the Middle East, where they recently hired local staff to drive expansion.

One of the most striking cases shared by Gribi occurred at a refinery where an ultrasonic sensor was installed, despite the plant's initial skepticism about the presence of corrosion. For a full year, no significant changes were recorded, until just three weeks later, a loss of 40 thousandths of an inch (0.04") of wall was detected in a pipeline. This extreme corrosion rate triggered immediate alerts.

The discovery identified the cause as a change in the composition of the processed crude oil. Based on the data recorded by the sensor, the plant decided to cancel future crude oil changes , completely modifying a strategy already planned for the remainder of the year. This action prevented major structural damage and represented millions of dollars in savings in potential repairs and plant shutdowns.

Gribi noted that the next step is to integrate this data with process information, enabling new real-time operational optimization strategies. Eddyfi Technologies is actively working to offer solutions that compare process trends with wear rates, opening a new era in intelligent asset management.

For more AMPP 2025 content, visit our YouTube channel and LinkedIn profile.

Source: Inspenet.