Welding inspection is entering a new stage of digital transformation thanks to Silveray, a technology startup out of the University of Surrey. In conversation during the ASNT 2025 convention, Norman Stapelberg, Chief Commercial Officer, presented a digital X-ray detector that promises to modernize industrial inspection with a lightweight, accurate and reusable solution.

Silveray develops direct conversion detectors using its NPX® technology, a semiconductor ink sensitive to X-rays and gamma rays. This innovation creates thin, flexible panels that capture high-resolution digital images, eliminating the need for traditional film.

The technological basis of this development lies in direct conversion, a system that transforms X-rays into electrical signals without the need for intermediate elements, such as scintillators. This translates into higher spatial resolution; in the model presented, the pixels are 126 microns, but since the conversion is direct, the quality is comparable to an image with pixels of 100 microns, thus surpassing the performance of conventional systems.

One of the sectors most benefiting from this technology is weld inspection in pipelines. For decades, the standard practice has been to wrap the pipe with radiographic film, take the image and then chemically process it to obtain the results. This process is slow, generates waste and requires prolonged physical storage.

One of the sectors that has benefited most from this technology is pipe weld inspection. For decades, the standard practice has been to wrap the pipe in radiographic film, take the image, and then process it chemically to obtain the results. This process is slow, generates waste, and requires prolonged physical storage.

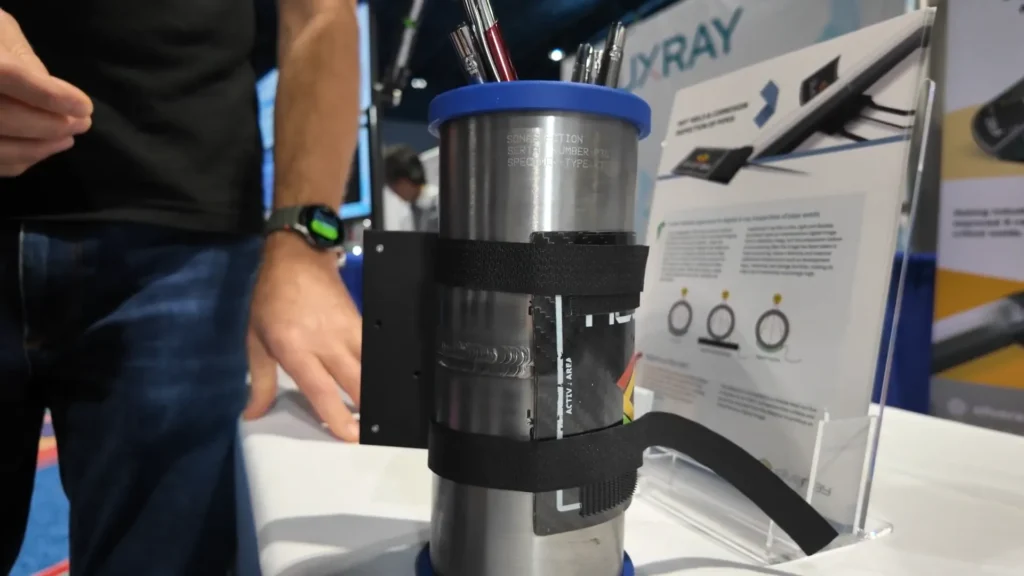

With the Silveray panel, the operation is simplified: the inspector only needs to wrap the detector around the pipe, secure it with the built-in Velcro straps and capture the digital image instantly.

The digitization of welds brings with it a significant change in data management and traceability. As Stapelberg explained, in regulated industries such as nuclear, where images must be retained for up to 75 years, storing them digitally represents a significant advance in document efficiency and in reducing the physical space needed for archiving.

In addition, this device can replace at least 1,000 radiographic films, thus decreasing waste generation and the need for chemicals for developing, having a direct effect on industrial waste management.

Silveray plans to officially launch this first product in the first quarter of next year. The company is already working on a larger version, twice the size of the current panel, to cover more inspection area in a single shot.

In his medium-term vision, Silveray seeks to position itself as a benchmark in digital non-destructive inspection solutions. Its approach combines material science, advanced electronics and usability, with the aim of digitizing critical processes that until now have remained anchored to analog technologies.

For more content about ASNT 2025, please visit our LinkedIn profile.

Source: Inspenet.