During the 2025 edition of the ASNT conference, one of the most relevant events in the non-destructive testing (NDT) industry, Jay Zimmerman, Sales Manager of 3E NDT, shared the company's main innovations in digital inspection.

Zimmerman highlighted the company's commitment to technological innovation, showcasing products that respond to the demands of the industrial present and anticipate the needs of the future. 3E NDT's participation in the event served as a showcase to exhibit the latest advances in digital radiography, automated ultrasound and portable inspection solutions.

3E NDT offers a full range of equipment and supplies for all NDT modalities; at trade shows such as ASNT, the company prioritizes high-impact technologies such as digital radiography and automated ultrasonic detectors, aimed at improving accuracy, traceability and speed in demanding industrial environments.

According to Zimmerman, the equipment is used by technicians to evaluate structural integrity in a wide variety of applications, from bridges and pipelines in the oil industry to critical components in aircraft. Depending on the environmental conditions and the purpose of the inspection, the professionals select the appropriate mode, thus optimizing the results of the analysis.

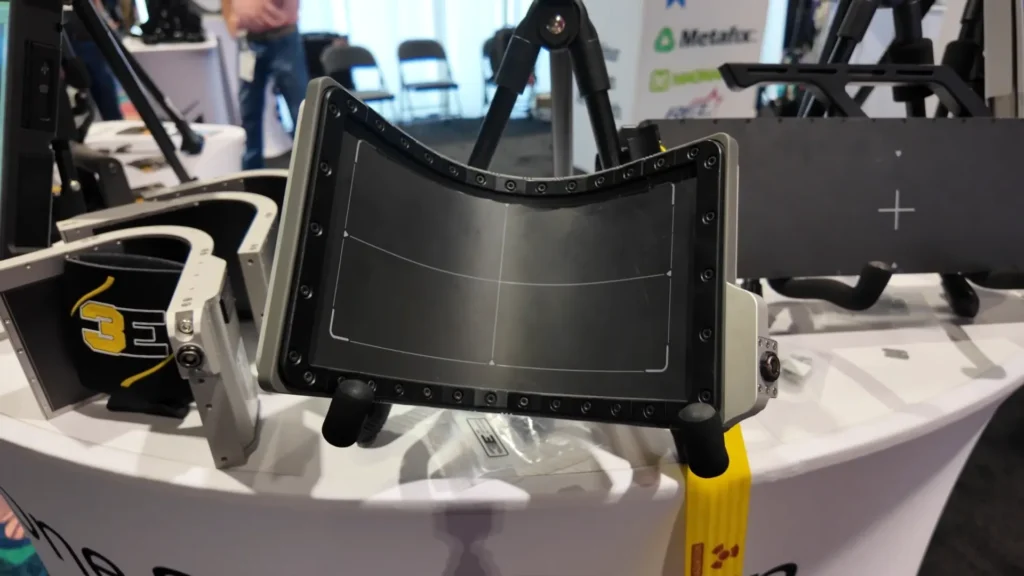

One of the highlights of the interview was the presentation of the flexible digital panel, one of the recent innovations in the 3E NDT portfolio. This detector can be adapted to curved surfaces such as pipes or fuselages, which represents a significant advantage in terms of versatility and coverage during inspections.

Digital radiography, Zimmerman explained, allows images to be captured directly in digital format, eliminating the use of physical film and chemicals. This saves storage space, while reducing operating times and improving overall process efficiency. "Our customers greatly appreciate the ability to go completely digital," he said.

With this transition, traditional archives full of drawers with radiographic plates are avoided and accessibility to records is improved, facilitating audits, comparisons and historical analysis.

Another innovation presented by 3E NDT at ASNT 2025 was the 200 kV portable X-ray tube, completely battery-operated, which allows inspections in the field without relying on electrical connections or heavy generators.

Zimmerman explained that, until a few years ago, technicians had to carry large cables and use external power supplies to operate radiographic equipment. Today, thanks to this portable solution, it is possible to perform high-quality inspection in remote or hard-to-reach conditions or difficult-to-access conditions with greater ease and less logistical preparation.

This type of technology is especially useful in extended infrastructure projects, such as transmission lines, offshore platforms or industrial facilities far from urban centers.

The participation of 3E NDT at the ASNT 2025 conference made it clear that the company remains committed to digital radiography as a central tool in the transformation of industrial inspection processes. Its ability to offer advanced, portable and efficient solutions positions it as a strategic partner for companies looking to improve their processes without compromising safety and quality.

For more content about ASNT 2025, please visit our LinkedIn profile.

Source: Inspenet.