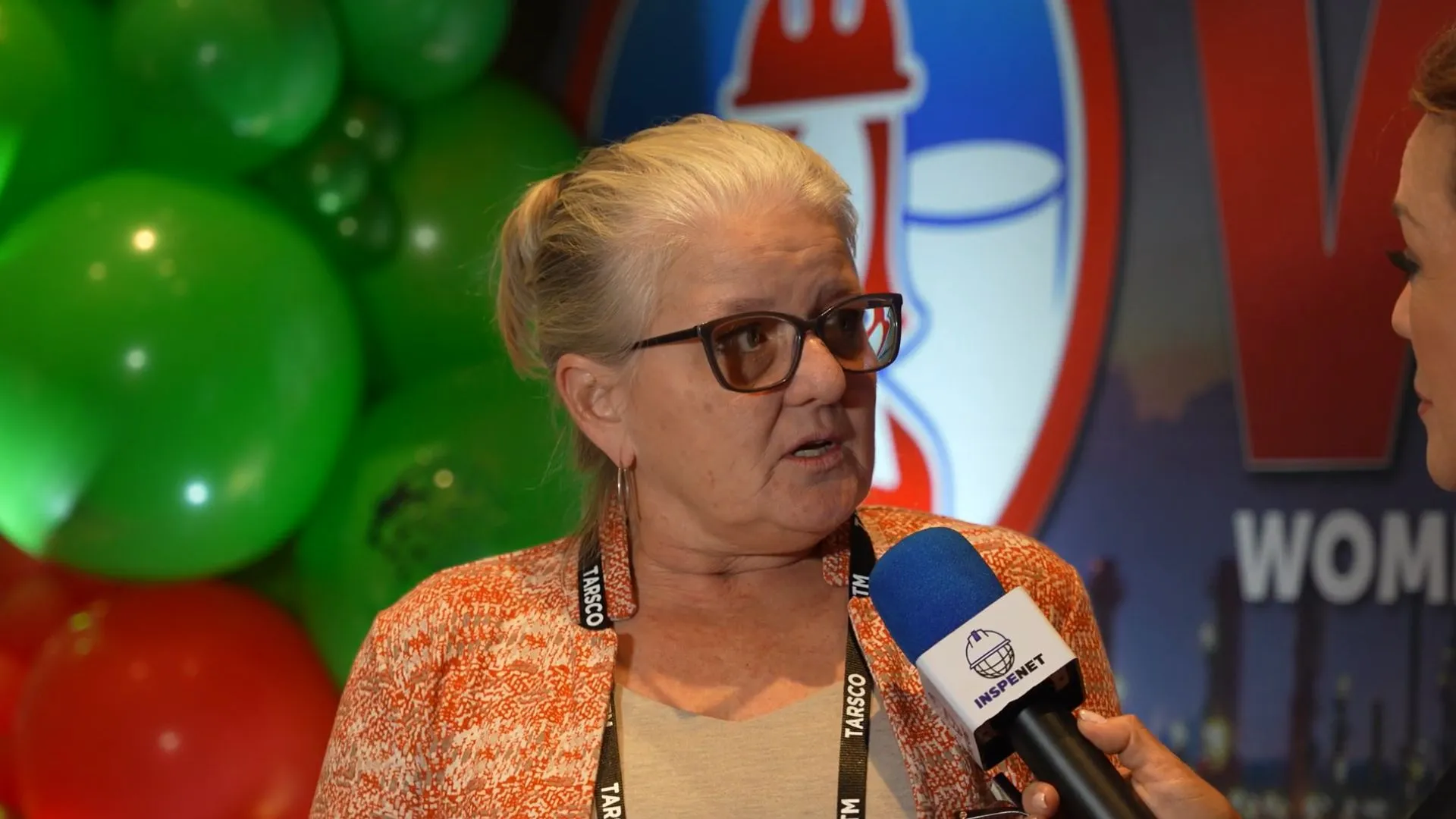

During the NISTM meeting, Kimberley Hayes, president and founder of Valkim Technologies, shared the progress and evolution of the Women in the Tank Industry (WITI) group, an initiative that started as a small informal meeting and has now established itself as a professional support network for women in the industrial tank storage and service sector.

Valkim Technologies support network

According to Hayes, the group arose spontaneously when a small group of 15 women came together to share experiences, strengths and needs in a traditionally male-dominated industry. Through the support of the NISTM organization, the movement grew exponentially from 15 to 150 members in just one year.

The support and visibility provided by Jim, Janelle and the entire NISTM team was crucial.

Her confidence in the message allowed many more women to feel part of this community.

Hayes stated.

The WITI group seeks to create meeting spaces, and strengthen women’s professional development through mentoring, networking and a focus on collaboration. Hayes mentioned the importance of breaking the “boys club” model and fostering an environment where women can openly share their needs, questions and career opportunities through platforms such as their private LinkedIn group.

During the conversation, Hayes emphasized that the growing female participation coincides with the technological transformation of the sector. The integration of digital solutions, artificial intelligence and robotics has decreased the reliance on intensive physical labor and enhanced the value of strategic and multidisciplinary thinking.

“Innovation happens when we change the way we look at things,” Hayes noted, quoting her favorite Wayne Dyer quote. For her, women bring fresh perspectives, the ability to multitask and the creativity to challenge decades-old established processes.

As an example, he mentioned the case of tank seal inspection, a process that has been carried out manually for years. Today, technologies such as robotics already make it possible to perform these tasks more safely and efficiently.

During the pandemic, Hayes decided to start her own business with the goal of accelerating innovation in the industry. She was inspired by a customer’s challenge to develop a non-electric robot for inspection in hazardous areas, embarking on a journey to design and build a prototype in her garage using a Coca-Cola crate, lawnmower wheels, and pneumatic drills.

In just three days the robot was moving. Two years later, that prototype evolved into the world’s first IECEx Zone Zero ATEX inspection robot, a simple, modular,dummy proofplatform with operational capabilities in demanding environments.

As a speaker at the event, Hayes said that her presentation is a direct message to the industry: the practice of “it’s always been done this way” is no longer acceptable. She also argued that continuing to expose personnel to hazardous environments, when viable technological alternatives exist, represents an unnecessary risk and a disconnect between the inspection and operational areas.

Source and photo: Inspenet | Valkim Tecnhologies