In industrial plants, the inlaysoIn industrial plants, mineral encrustations In industrial plants, mineral fouling acts as an invisible barrier that reduces flow in pipelines and drives up operating costs. This buildup, similar to limescale in a kettle but on a large scale, represents a persistent challenge for the energy and water treatment sectors. water treatment.

Now, a team of Rice University engineers is proposing an alternative path: lab-grown synthetic diamond films capable of repelling these deposits.

A natural barrier against minerals

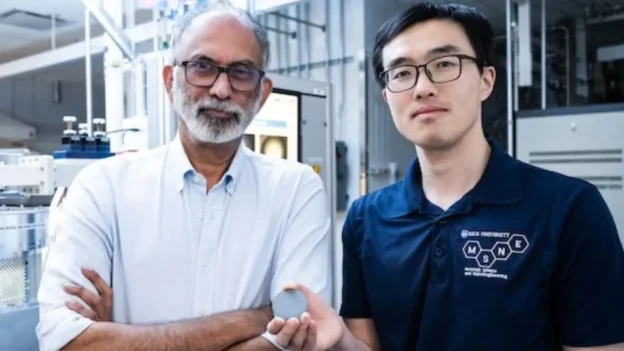

The team led by Xiang Zhang and Pulickel Ajayan developed diamond films using a technique known as microwave plasma chemical vapor deposition (MPCVD). By modifying the surface with specific chemical terminations, such as nitrogen, they achieved remarkable resistance to initial scale formation.

Tests showed that nitrogen-treated diamond accumulated more than ten times less minerals than other treatments with oxygen, hydrogen or fluorine. This resistance is attributed to a dense layer of water that forms on the surface, making it difficult for mineral ions to adhere.

Applications in key sectors

The same chemical modification was successfully applied to boron-doped diamond electrodes used in electrochemical processes. electrochemical processes. The results showed a significant reduction in accumulation without compromising performance.

This versatility makes the coating an attractive option for industries with critical needs, such as water desalination, power generation and manufacturing.

Efficiency without environmental impact of synthetic diamonds

Currently, common solutions for scaling include mechanical cleaning and chemical products, both with costly or contaminating side effects. Against this, diamond coating emerges as a passive, scalable and temperature stable alternative, without the need for constant intervention or additives.

Jun Lou, one of the project’s researchers, points out that the process of applying these films is adaptable and economical, making it viable for large-scale industrial implementations.

With these findings, Rice University opens a new path toward cleaner, more efficient and sustainable industrial systems, where diamond is no longer a jewel but a technical ally. The study was published in the journal ACS Nanospecialized in nanotechnology and materials science.

Source and photo: Rice University