Inspenet, October 13, 2023.

Scientists at the Massachusetts Institute of Technology (MIT) have recently developed a highly precise robotic hand that has the advantage of being easier to extend. This is because their parts can be manufactured using common techniques such as 3D printing and laser cutting.

The robotic hand, detailed in a paper published at the 2023 IEEE International Conference on Soft Robotics (RoboSoft) , is based on a modular structure composed of several building blocks that can be rearranged to perform different movements.

The main purpose of the recent work carried out by the team was to develop a robotic limb that was flexible in nature that did not depend on highly advanced and expensive components. However, this flexible hand was intended to have the ability to carry out more complex movements compared to conventional robotic claws that are constructed exclusively of rigid materials. This would ultimately improve the robots’ capabilities in terms of object manipulation.

Independent robotic hand

The modular robotic hand developed by the MIT research team can be easily adjusted to suit various applications. For example, researchers have the option to add or remove fingers, as well as rearrange their elements in different ways to achieve a variety of grip types or improve their performance in particular situations.

Surprisingly, both the rigid and flexible elements used in the creation of the new robotic hand are simple to manufacture. The “bones” that make up the framework of the hand can be produced by 3D printing, and the magnets, sensors and wires they contain are commercially available.

To make the outer layer that surrounds the bones, the team followed a two-stage molding process. Initially, they created different mold pieces using 3D printing and later, they used those pieces to shape the silicone that covers the fingers.

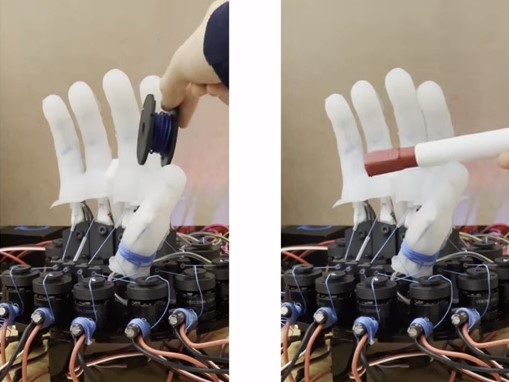

Within their research, the researchers manufactured a prototype of a robotic hand with five fingers and evaluated its operation. They concluded that the limb could successfully execute various types of grasping, emulating the way human hands grasp and hold different objects. This robotic hand demonstrated adequate firmness in grasping a variety of objects, both rigid and flexible, of various sizes, including a plastic cup, a pen, and a round plastic ring.

It is proposed that the robotic hand be further developed and undergo additional testing to refine and validate its abilities. As it evolves, it could be integrated with other robotic limbs with the goal of creating adaptive humanoid robots that are especially adept at manipulating objects.

Follow us on our social networks and stay up to date with our news!

Inspenet: https://inspenet.com/

YouTube: https://www.youtube.com/@inspenet

LinkedIn: https://www.linkedin.com/company/inspenetnetwork

Facebook: https://www.facebook.com/inspenetnetwork

Instagram: https://www.instagram.com/inspenet/

Source: https://techxplore.com/news/2023-10-human-inspired-robotic-based-modular.html