A subsidiary of Dongfeng Motor Corporation has signed a strategic agreement with Ubtech Robotics, in which it will implement Ubtech’s Walker S robot in its vehicle manufacturing processes, moving into a new era of mobility assembled with state-of-the-art robotic technology.

Since the late 1960s, Dongfeng Motor Corporation has been operating and is one of the four major Chinese state-owned automakers. Although the Chinese government supports Dongfeng’s products, its presence in the United States is limited.

Dongfeng and the production of vehicles with humanoid robots

Dongfeng Liuzhou Motor Co., Ltd, a subsidiary of Dongfeng Motor Corporation, has been producing vehicles for as long as its parent company. Recently, it has focused on crossovers and minivans under the Fengxing brand, as well as pickup trucks and other vehicles for the Lingzhi and Jingyi brands.

To improve the production of these vehicles, Dongfeng Liuzhou Motor has turned to Ubtech Robotics. Founded in 2012, which offers a variety of robots capable of cleaning, delivering items, providing fitness training and even offering companionship. However, Dongfeng’s main focus is on one of Ubtech’s most advanced models: the Walker S humanoid robot which is already assisting in the construction of electric vehicles for Chinese manufacturers such as NIO.

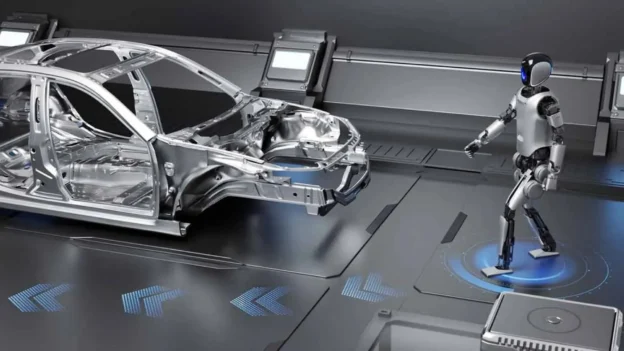

According to a report by Car News China, Dongfeng Liuzhou Motor and Ubtech Robotics have signed a strategic cooperation agreement to deploy the industrial-grade humanoid robots Ubtech’s industrial-grade humanoid robots on Dongfeng’s assembly lines in China. Walker S robots will perform tasks such as seat belt inspection, door lock testing, body quality checks, oil filling and label applications, working alongside traditional automated manufacturing equipment to handle complex scenarios without human intervention.

Walker S robot features

The Ubtech Walker S robots, which are 1.7 meters tall, are equipped with a “fusion control” algorithm that enables real-time communication with factory systems and data exchange. These robots operate with 41 high-performance servo joints and have advanced sensory capabilities that allow them to perceive their environment and interact with objects and people. The following video shows the humanoid performing some tasks.

Walker S communicates in real time with factory systems. Source: Ubtech Robotics

With this new partnership, Dongfeng Motor seeks to optimize its production processes using state-of-the-art robotic technology, highlighting its capabilities as an example of the future in automotive manufacturing. We have seen other manufacturers such as Tesla introduce their own humanoid robot, Optimus, suggesting a future where vehicle production could be continuous and without human error.

The adoption of humanoid robots in the automotive industry promises to improve efficiency and precision in production and raises interesting questions about the future of human factory labor. The combination of human skills with the precision and tirelessness of robots could redefine traditional roles in manufacturing.

Follow us on social networks and don’t miss any of our publications!

YouTube LinkedIn Facebook Instagram X

Source and photo: electrek