Japan’s Mitsubishi Heavy Industries (MHI) has developed an underwater robot capable of performing non-destructive inspections of nuclear reactor vessels . nuclear reactor reactor vessels underwater. This technology, known as A-UT Machine, is designed to operate in extreme conditions where human presence is not feasible, such as the high radiation and pressure inside the reactors.

Underwater robot for inspection in nuclear environments

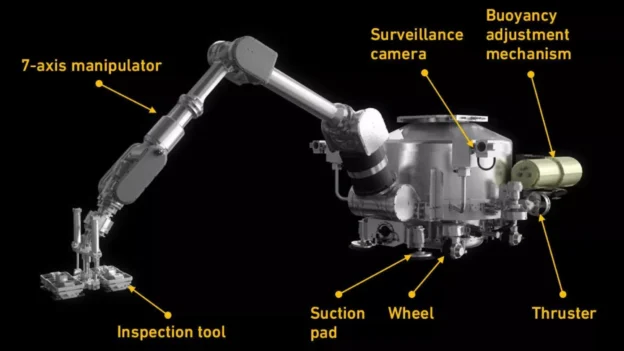

The robot uses a propulsion navigation system and wheels to move both in the water and on the internal surfaces of the reactor. With a length of 1.8 meters and a weight of 400 kg, the unit can descend to a depth of 20 meters.

It uses a seven-axis robotic arm with millimeter precision and a load capacity of up to 10 kg, equipped with a tool changer that allows the inspection devices to be adapted according to the need for maintenance.

Accuracy and efficiency in control

Thanks to its design, the A-UT can adhere to the vessel walls by means of suction cups and perform ultrasonic tests. ultrasonic tests while maintaining its position. The robot’s location and orientation are tracked in real time using a camera and optical triangulation system.

Control is completely remote via a desktop computer and joystick, allowing operators to work in a safe environment.

Since 1995, this robot has been used in 46 pressurized water reactor (PWR) installations in Japan, validating its effectiveness in the field. In addition, it has been recognized by the Japan Maintenance Society as the first “Maintenance Heritage,” a category that highlights relevant technologies in the preservation of critical infrastructure.

Key role in the energy transition

With nuclear power gaining ground again in Japan in response to the challenges of climate change and energy security, systems such as the A-UT become strategic. They allow nuclear power plants to remain operational with higher inspection frequency and less human exposure to risk, supporting operational continuity with higher safety standards.

This development underscores the role of automation and robotics in the modernization of the energy sector, especially in tasks where human intervention is limited for technical safety reasons.

Source and photo: Mitsubishi Heavy Industries