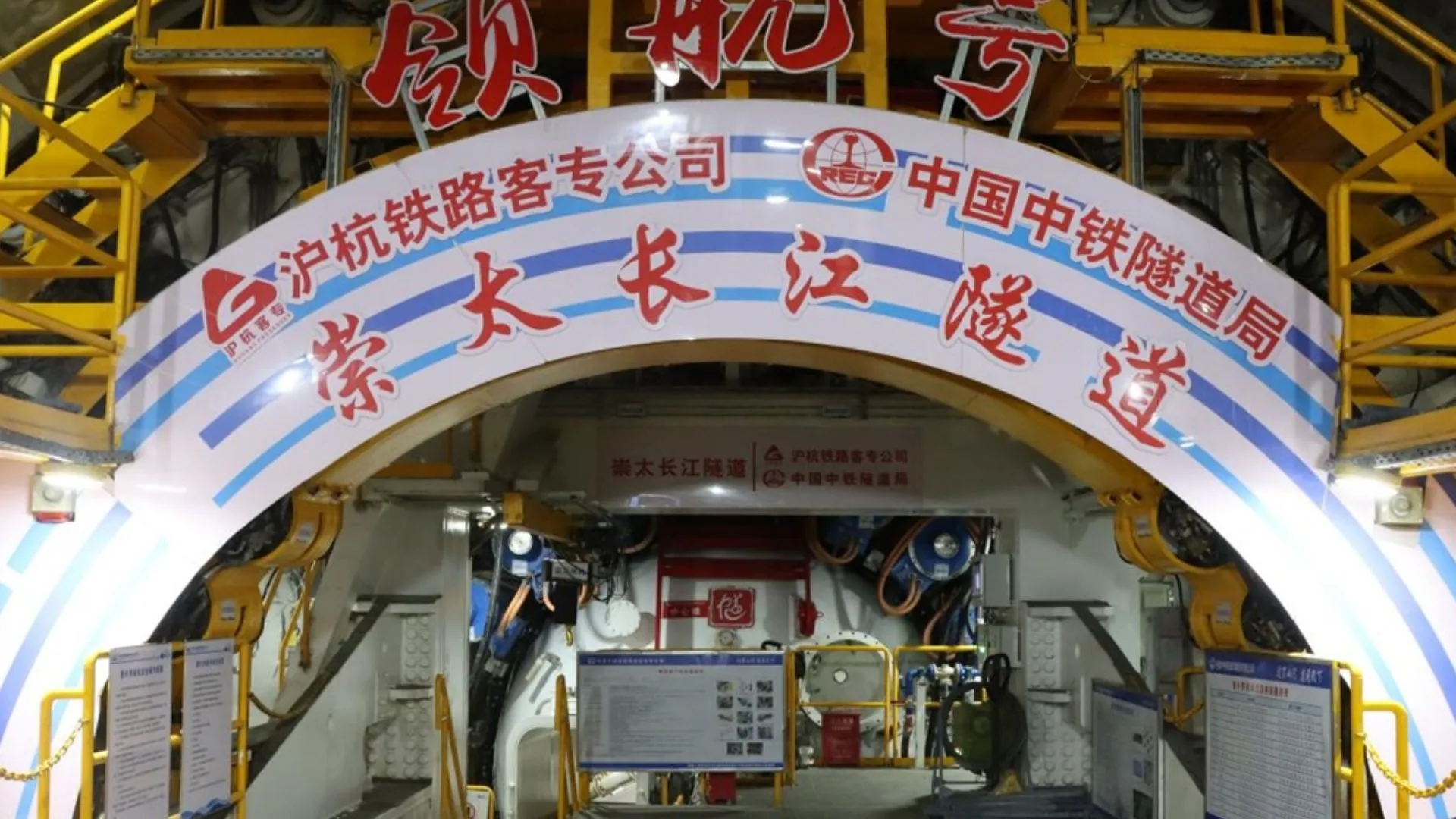

In a new step for the high-speed rail infrastructureChina’s Linghang tunnel boring machine reached 10,000 meters of continuous excavation under China’s Yangtze River on Tuesday, leaving it just 1,000 meters short of completing the southern section of the Chongming-Taizhou tunnel.

This achievement makes Linghang the first shield machine with a diameter of 15 meters to achieve this distance without interruption, paving the way for the completion of a key tunnel for a rail line that will enable river crossings at speeds of up to 350 km/h.

Chinese tunnel boring machine and autonomous drilling technology

Linghang is equipped with an intelligent control system capable of adjusting internal pressure, anticipating ground conditions through predictive data and correcting its trajectory without human intervention. This development has allowed the monthly headway to reach 718 meters, setting a new record for tunnels of this size.

The artificial intelligence navigation and monitoring system based on artificial intelligence has gradually replaced manual operation, improving drilling accuracy and reducing risks in underwater environments.

Impact on regional connectivity

Once operational, the tunnel will significantly reduce travel times between strategic Yangtze Delta cities such as Shanghai, Nanjing and Hefei. This improvement will be critical to the integration of the high-speed rail corridor in the region and will strengthen the development of the river’s economic belt.

China leads the global tunnel boring machines market

Since the creation of the first 15-meter domestic shield TBM in 2017, China has developed larger and larger models, consolidating a dominant position with more than 70% of the global TBM market. Linghang represents the technology of this industry, not only for its size but for incorporating fully autonomous operation throughout its process.

The advancement of this type of technology puts China at the forefront in subway engineering solutions and sets a precedent in the construction of large-scale railway tunnels.

Source and photo: Global Times