The Korea Institute of Machinery and Materials(KIMM) has developed an automated system that can detect up to 16 food pathogens in less than an hour. This equipment integrates separation, pretreatment and molecular diagnostics in a single platform, and is designed for direct use in schools, food production centers and government agencies.

Real-time diagnosis of 16 pathogens

Through its one-touch operation, the system eliminates the need for highly qualified personnel or complex processes. The analysis is performed on site, which facilitates immediate response to potential contamination risks. This technology aims to reduce current detection times, which can take up to a week with conventional methods.

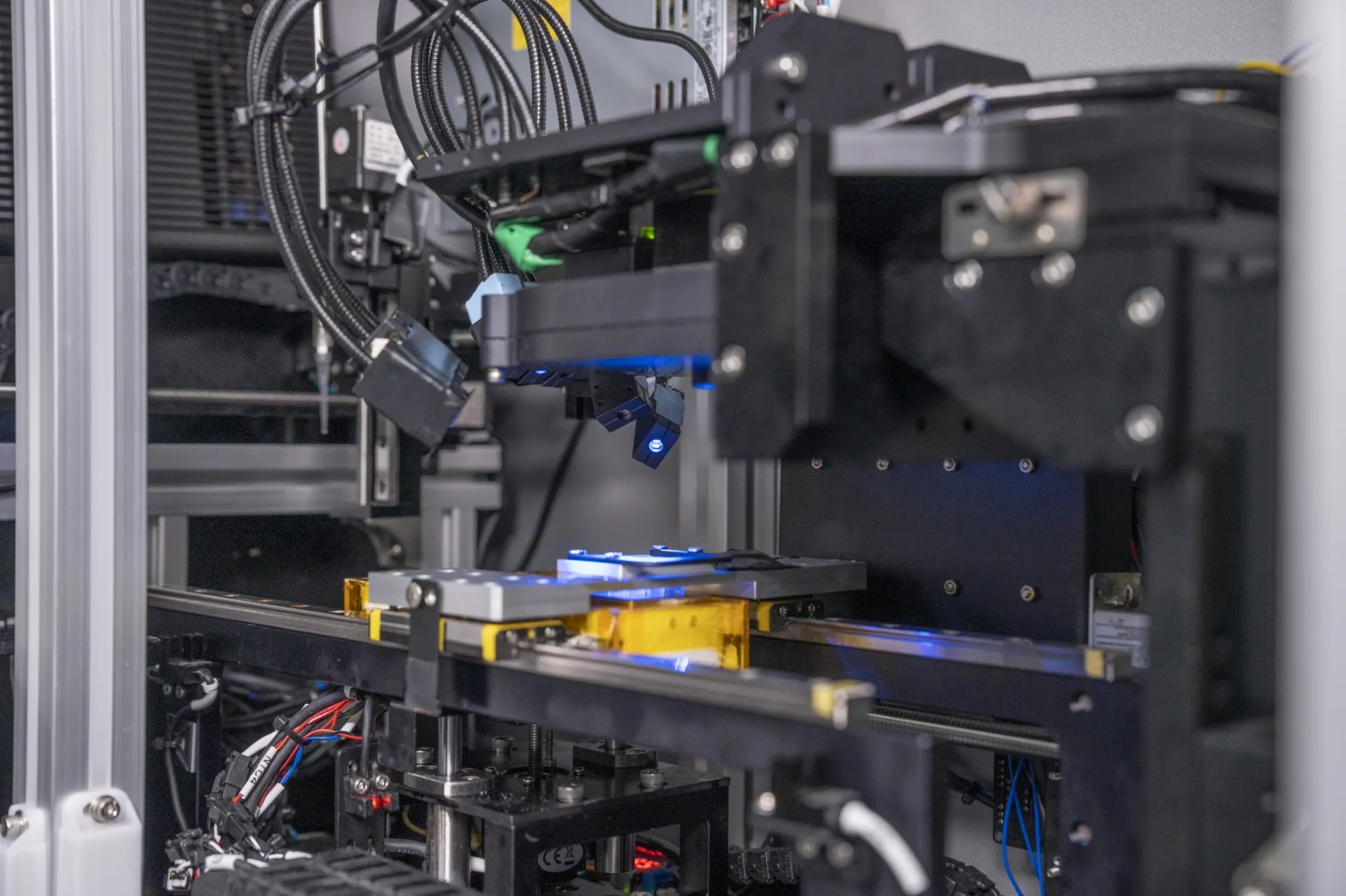

The device separates pathogens pathogens without disturbing the food sample using hydrodynamic forces generated by high-speed propellers. Subsequently, the residues are filtered by multilayer membranes. In parallel, the genetic material is subjected to a mechanically controlled thermal amplification process, completing 40 cycles in 15 minutes. The reading of results is performed with fluorescence sensors and integrated software.

The system is being tested at two demonstration sites with more than four categories of food products. Tests have confirmed both its accuracy and efficiency in the field. This innovation has been developed under the R&D program of the Korean Ministry of Internal Affairs and Security, which focuses on technological solutions with high social impact.

The project’s principal investigator, Chanyong Park, mentioned that this breakthrough can turn the prevention of foodborne diseases. Meanwhile, Dongkyu Lee, a specialist from KIMM’s diagnostic sensor laboratory, mentioned that comprehensive process automation is an improvement in food safety management.

Source and photo: KIMM