The Korea Institute of Machinery and Materials(KIMM) has unveiled the development of portable robots that can be used as an extra piece of clothing, with the creation of an automated weaving system that enables the mass production of “textile muscles.”

The flexibility and adaptability of portable robots

This technological breakthrough utilizes ultralight muscle fibers based on alloy with shape memory(SMA), creating a new way to build and engineer robots that can assist people in physical activities.

The robots are designed to assist joints such as the elbow, shoulder and waist, often relied on pneumatic actuators or heavy motors, making them bulky, noisy and uncomfortable for extended use.

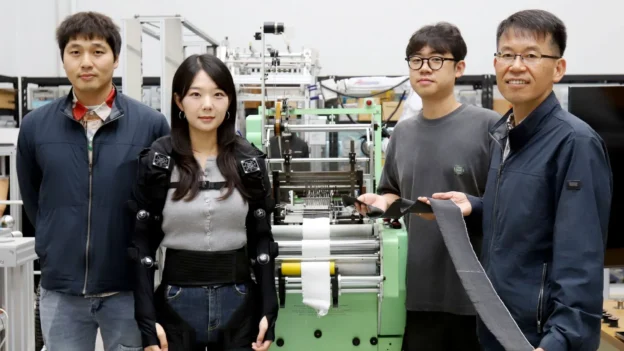

However, through research led by Dr. Cheol Hoon Park at KIMM’s Advanced Robotics Research Center , a much lighter, more flexible and efficient solution has now been developed: textile muscle actuators.

This new system uses shape-memory alloy wire that is only 25 μm in diameter, and when compared to a human hair, represents only about a quarter of the thickness. This wire is processed in the form of a spiral thread, which enables the

The robot has been tested in clinical trials at Seoul National University Hospital(SNUH), where it was shown to improve the range of motion of patients with muscle weakness, including those with Duchenne muscular dystrophy, by more than 57%. This portable device has the potential to improve the daily lives of those suffering from muscle weakness, giving them greater independence and reducing the burden on caregivers.

The technology has been developed with the support of institutions such as the Ministry of Trade, Industry and Resources (MOTIR) through the Basic Robotic Technology Development Program, and the Lee Kun-hee Project for supporting research on childhood cancer and rare diseases.

Our development of continuous mass production technology for textile muscles, an essential component of wearable robots, will significantly improve the quality of life in sectors such as healthcare, logistics and construction.

We will continue to develop KIMM’s wearable robotics technologies to accelerate their commercialization and lead the global wearable robotics market.

Dr. Cheol Hoon Park, principal investigator, KIMM Advanced Robotics Research Center.

This development has been recognized as one of KIMM‘s most important research, winning the KIMM 2024 Best Research Award. The results of this project were published in the October 2025 issue of TNSRE (IEEE Transactions on Neural Systems and Rehabilitation Engineering), one of the most influential journals in the field of rehabilitation engineering.

Source and photo: KIMM