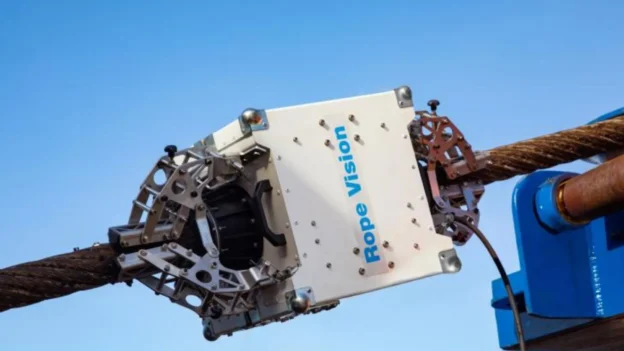

Rope Vision is the new automated system developed by Huisman to visually inspect steel wire ropes on high-capacity cranes. Its objective is to reduce downtime and anticipate failures through a technical analysis of critical parameters.

Rope Vision and its application to predictive maintenance

The tool combines high-resolution images with crane operational data and rope condition. Thanks to this integration, teams can make informed decisions based on actual rope wear, avoiding inaccurate manual inspections.

The system uses four high-speed cameras that capture a full 360-degree view, allowing continuous scanning at 45 meters per minute. It is compatible with metallic cables between 50 and 72 millimeters in diameter.

Technical evaluation according to international standards

Rope Vision measures variables such as diameter, pitch length, breakage and deformation. From this data, a severity classification is generated according to the standard ISO 4309facilitating maintenance scheduling based on objective criteria and not on predefined intervals.

This approach improves safety in lifting operations by reducing the risk of sudden failures and optimizes asset management by extending rope life without compromising operation.

A paradigm shift in cable management

Martijn Reissenweber, Director of Services at Huisman, emphasized that this solution allows moving from reactive maintenance to a proactive strategy.

With Rope Vision, our customers can anticipate the ideal time to make adjustments, avoiding unnecessary interruptions.

Reissenweber.

The implementation of this type of technology positions the company as a leader in innovation in the industrial hoisting sector, meeting the requirements of efficiency and safety in the energy industry. and safety requirements of the energy and infrastructure and infrastructure industry.

Source and photo: Huisman Equipment