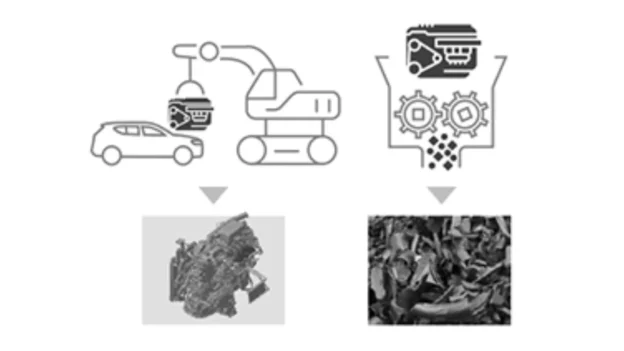

Honda R&D announced the development of a “chemical sorting” technology to separate solid contaminants from end-of-life automobile-derived plastic waste. The technology will enable the extraction of high-purity reusable plastics, overcoming the limitations of recycling methods and marking a significant advance in the automotive industry’s circular economy.

Plastic waste technology

The company plans to build a pilot plant with a processing capacity of up to 350 tons per year, with the goal of verifying the technology by the end of 2026 and implementing it around 2029.

Unlike physical sorting, which requires manual or mechanical separation, the new method dissolves the resin in a solvent to remove contaminants such as metal inserts, hoses, rubber gaskets and glass fibers. This innovation improves the separation rate to more than 99%, enabling the recovery of plastics suitable for closed-loop recycling.

The technology uses coarse-mesh filters and centrifuges to remove contaminants of all sizes, enabling a continuous and scalable process to be established, minimizing the need for maintenance and filter replacement. Through these features, Honda has been able to expand the range of recyclable parts, achieve economic viability, and facilitate the practical application of the technology on an industrial scale.

In addition, this solution contributes to the reduction of CO₂ emissions, because it allows for the recycling of fiber-reinforced plastics reinforced plastics that were previously incinerated. It also improves recycling performance by avoiding resin loss during the separation process and allows the recovery of plastic in pellet form, ready for reuse in automotive components.

Source and photo: Honda R&D