By : Franyi Sarmiento, Ph.D., Inspenet, July 14, 2022

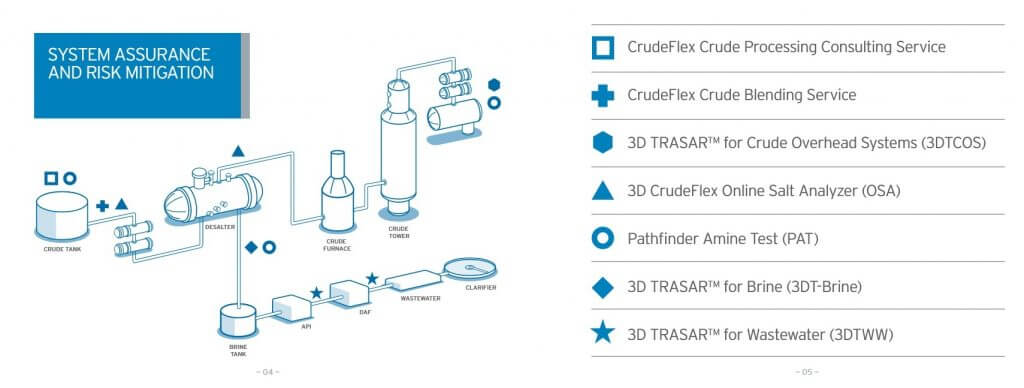

Ecolab developed CrudeFlex, a technological system that seeks to facilitate the automation and detection of faults in real time during the refining of crude oil.

Among the benefits of his proposal, the increase in profitability for specific solutions in the production chain stands out, which allows companies to achieve their objectives and cover their commercial needs.

“If refineries want to thrive in this increasingly challenging environment, they will have to improve or at least maintain current levels of reliability in their units while successfully processing more diverse feedstock in a timely manner,” said Esteban Guáqueta, Marketing Manager. of Ecolab in Latin America.

In the case of refineries, this solution represents a higher level of confidence in the systems as it mitigates and manages potential risks in crude or wastewater operations.

Mainly, it contributes to the resolution of corrosion and fouling due to operating deviations, which generate 90 percent of the problems and occur 10 percent of the time that the refinery is in operation.

Therefore, identifying and correcting this type of deviation in the process in real time, in addition to generating a history of failures in the short, medium and long term, allows complexes to save up to 5 million dollars per year and increase their profitability.

This Energy21 portal material has been edited for clarity, style, and length.