The BMW Group’s Steyr plant announces plans for series production of its third-generation hydrogen fuel cell system to begin in 2028. Currently, the competence centers in Munich and Steyr are developing prototypes, while the technology center in Landshut will manufacture key components such as the Energy Master, responsible for managing the power supply in ranges up to 800 volts.

The evolution of hydrogen propulsion systems

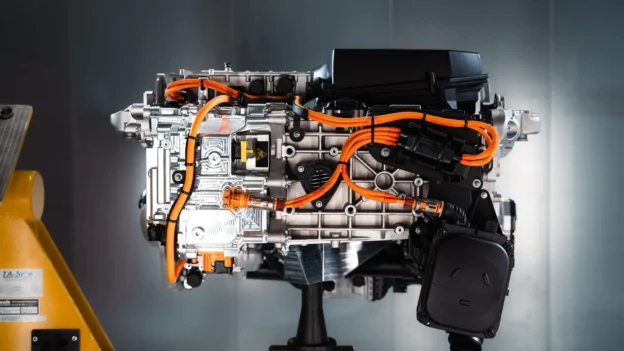

Since 2014, BMW has come a long way in the development of hydrogen propulsion systems. The first generation was supplied by Toyota and integrated into the 535iA model. From there, the second version powered the BMW iX5 Hydrogen in pilot tests. Today, the third generation is born from a deeper collaboration between BMW and Toyota, seeking efficiency, performance and adaptability in future platforms.

The new fuel cell system reduces its volume by 25 %, increases power density and is easily integrated into upcoming vehicle architectures. It also improves energy efficiency thanks to optimized components and refined operating strategies. The result: longer range, lower consumption and zero emissions.

The choice of Steyr as a production site is no accident. Its expertise in combustion and electric engines positions it as a key hub of BMW’s open technology approach. For its part, the Munich site leads process validation and efficiency tests, while Landshut produces specific hardware such as the housing and pressure plate.

BMW and Toyota strengthen their alliance with a common strategy: to develop a hydrogen-based propulsion system applicable to both commercial and passenger vehicles.

While new test benches are being built and the facilities in Steyr are being adapted, BMW is focusing on scalability and quality assurance. In parallel, the first prototypes of the Energy Master are being manufactured at the Dingolfing plant, completing the production ecosystem for this technology.

Source and photo: BMW Group