In a context where the solar industry is expanding rapidly and the pressure for sustainable materials is increasing, AIKO marks a turning point. Its new bet now is to replace traditional silver in the metallization of solar modules with copper interconnects, a more abundant, affordable and efficient material.

Why copper in solar modules?

To begin with, copper has a significantly lower electrical resistivity than the silver used in paste, which favors current collection and improves performance under high irradiation conditions. In addition, by eliminating the sintering process, thermal stress is reduced and contamination on the silicon wafer is minimized, extending the lifetime of the solar modules. solar modules.

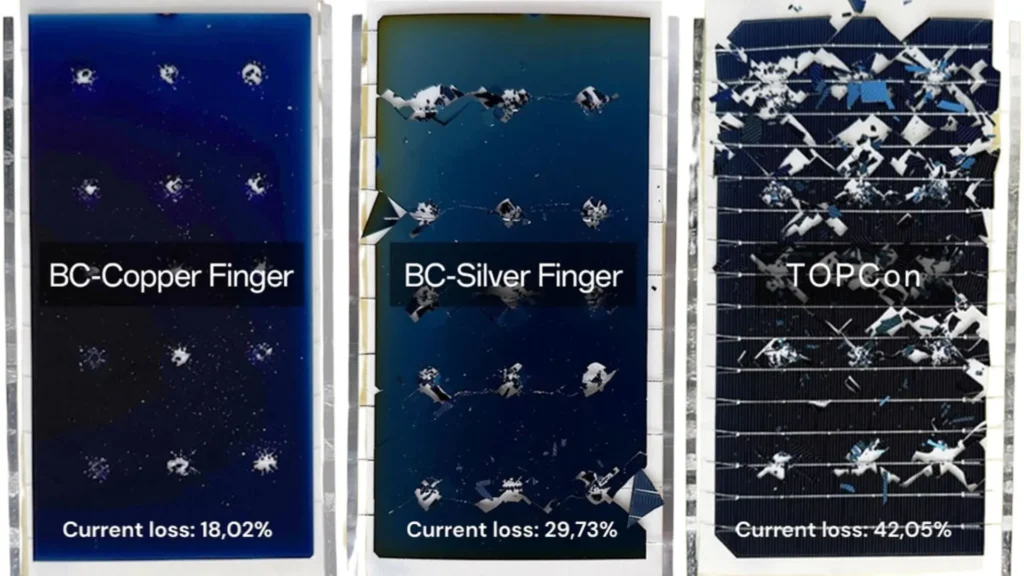

In addition, this innovation strengthens the mechanical resistance of the ABC modules. ABC modules. The copper solder joints achieve higher tensile strengths, allowing them to better withstand impacts and extreme environmental conditions. This translates into an ideal solution for exposed installations such as alpine roofs or floating systems. floating systems.

AIKO combines efficiency and sustainability

AIKO’s strategy redefines the balance between performance, cost and sustainability. Reduced maintenance costs and lower fire risk fire risk associated associated with its optimized thermal behavior strengthen the value proposition for EPCs and asset owners.

Finally, in an increasingly competitive European market, this technology offers a clear path to differentiation through superior energy efficiency, extended durability and alignment with decarbonization goals.

Follow us on social networks and don’t miss any of our publications!

YouTube LinkedIn Facebook Instagram X (Twitter) TikTok

Source and internal photo: AIKO

Main photo: Shutterstock