Voliro and Gresco UAS join forces to improve industrial aerial inspection in the U.S.

Some infrastructures such as power towers, industrial plants and telecommunication facilities will benefit from a safer and less invasive technical assessment.

Some infrastructures such as power towers, industrial plants and telecommunication facilities will benefit from a safer and less invasive technical assessment.

nT-Tao's C3 system goes into operation two months after assembly and seeks to validate a modular, high-density nuclear fusion architecture.

The system is being tested at two demonstration sites with more than four categories of food products.

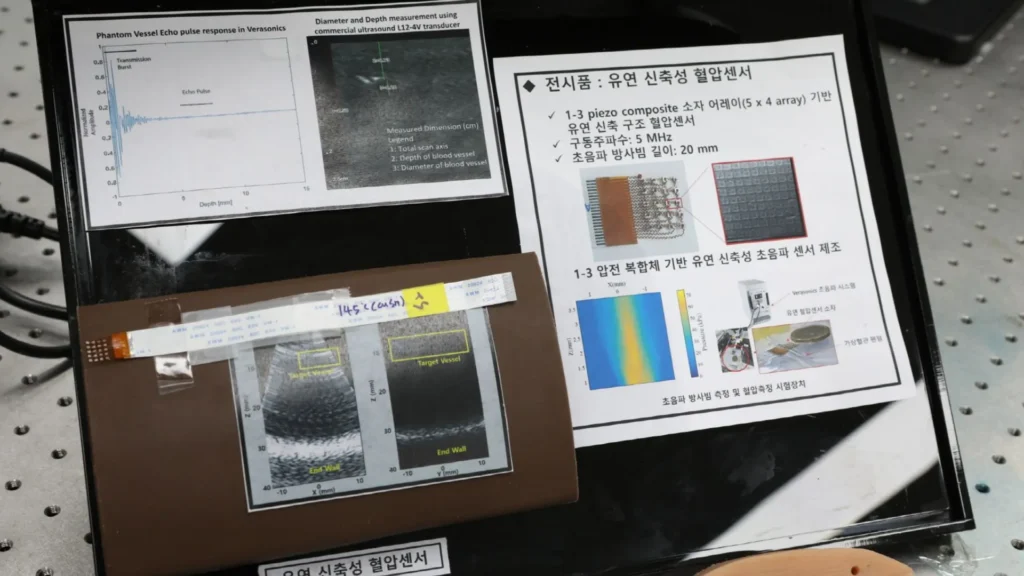

The sleeveless optical methods have inaccuracies due to motion, while this ultrasonic sensor overcomes these limitations by penetrating the skin and directly measuring deep arteries.

The objective is to convert agricultural residues into high-value resources through viable biotechnological solutions for the industrial sector.

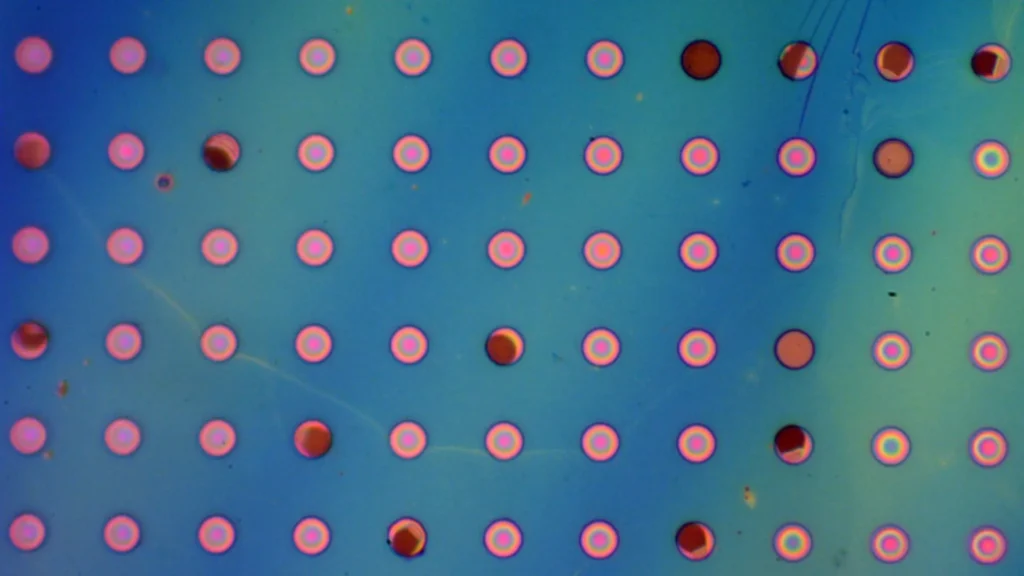

This bacterium is commonly found in the environment and can naturally establish biofilms on plastic materials.

PDCA produced with bacteria could replace PET due to its improved efficiency, purity and physical properties.

Researchers compare the dynamics of drones to the interaction between a surgeon and a nurse during an operation.

The clock is ticking towards December 2026 and chemical plants must accelerate their plans to meet WGC BREF requirements.

Because it is nearly impervious to gases, the polymer coating developed by MIT engineers could be used to protect solar panels, machinery, infrastructure and more.

This material is highly stable under extreme conditions and has the ability to self-repair.

AIMPLAS applies in vitro bioassays to detect risks in bio-based materials whose complexity prevents a complete chemical characterization.