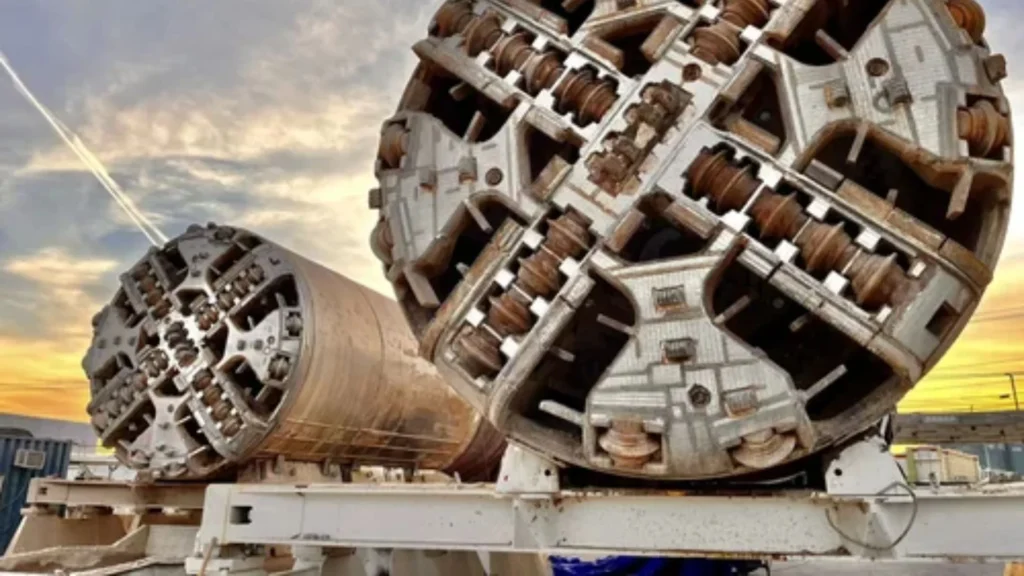

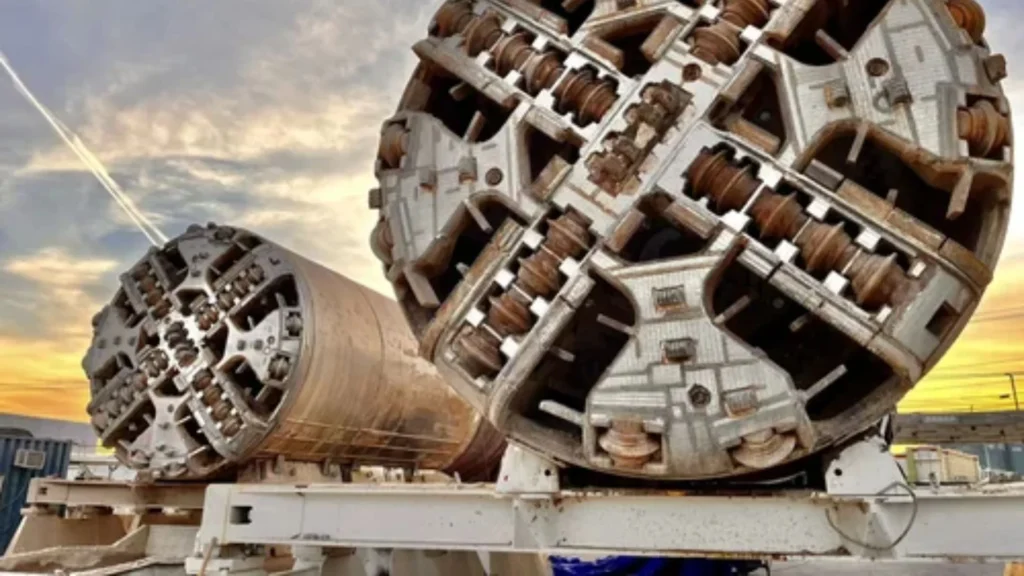

The Boring Company launches Prufrock-4, its new unmanned tunnel boring machine

The Prufrock-4 introduces continuous excavation and remote operation to reduce costs and accelerate tunneling projects throughout the Loop system.

The Prufrock-4 introduces continuous excavation and remote operation to reduce costs and accelerate tunneling projects throughout the Loop system.

The Changtai Bridge integrates road and rail at a 10 km crossing over the river.

The building uses recycled electric car batteries to store solar energy and reduce costs.

In addition to the bridge, there will be more than 40 km of new roads and highways, with three metro stations, some ten viaducts and several…

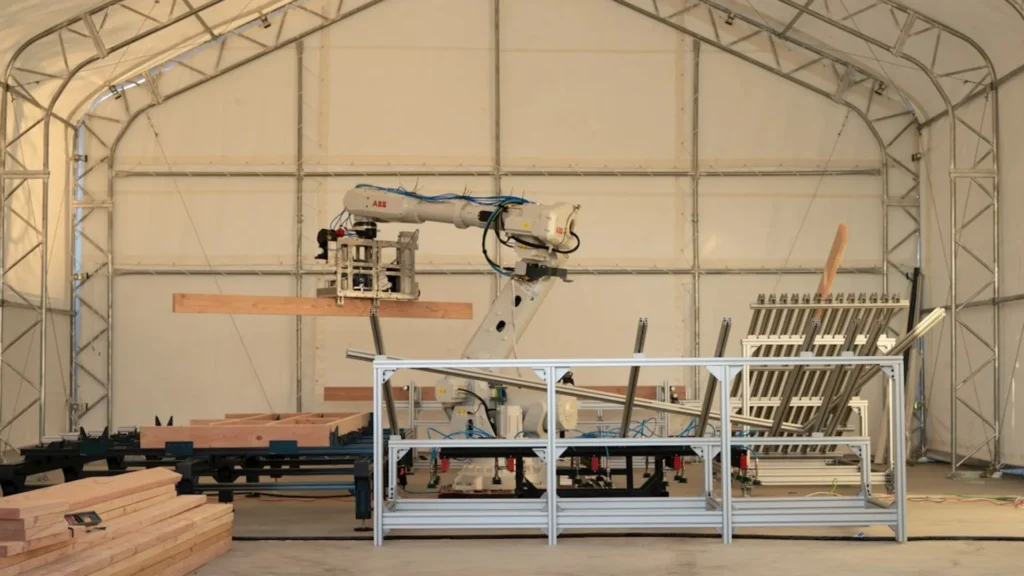

The mobile microfactory reduces construction time by 70% and costs by 30%.

A new technology promises to turn buildings into carbon sinks through materials that absorb CO₂ directly from the air.

Hermes is the first advanced reactor in the U.S. approved for construction with 3D printed molds.

Proven two-year reduction in track wear and settling due to the use of recycled rubber.

Qatar builds 2 schools of 40,000 m² using the world's largest 3D printers.

The bricks are fired at only 200 °C, reducing energy consumption by 80% compared to traditional bricks.

CivDot robots can mark up to 3,000 points per day with an accuracy of 8 mm, six times the speed of human work.

The Mayrit tunnel boring machine is capable of excavating up to 15 meters per day.