The nature of hydrocarbon production, storage and refining processes implies risks that must be known in order to focus maintenance resources on those components that present the greatest risk. In this way, measures can be implemented to minimize the occurrence of an undesired event and its consequences, increasing the reliability of the facilities.

For the maintenance area, this means a constant search for methodologies to increase the reliability, availability and useful life of the equipment that make up a facility, taking into account the reduction of costs associated with the failure of equipment and its components (repairs, replacements, production losses, among others).

Analysis of susceptibility to damage mechanisms

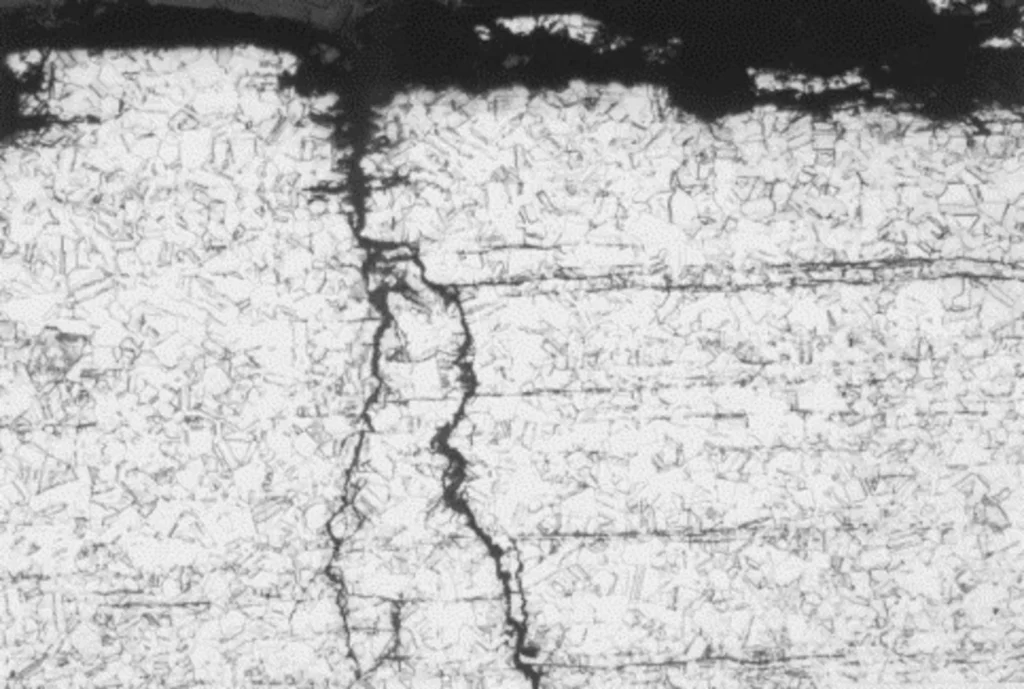

The identification of the damage mechanisms is carried out considering the equipment characteristics and its operating conditions and taking as a reference the indications in the API 571, which describes the most probable damages that occur in equipment (piping, pressure vessels and tanks) in the refining industry, in affected materials, critical factors, appearance or morphology of the damage, prevention/mitigation, inspection, monitoring and related mechanisms.

Knowledge of the damage mechanisms affecting the equipment allows us to select effective inspection methods to detect and characterize the damage. It is worth mentioning that Penspen has software that allows us to calculate the quantitative failure probability for the identified damage mechanisms.

Mechanical integrity – fitness for service (FFS) evaluation

The Mechanical Integrity analysis is performed based on the applicable national and international standards according to the type of equipment to be verified (ASME Section VIII, Div. 1, API 510, API 572, API 579, API 577, API 953, BS 7910 and API 1176). In some cases, it is necessary to develop a level III evaluation using finite element software.

The fitness-for-duty evaluation includes the following activities:

- Analysis of historical and current equipment information (year and code of construction, design pressure and temperature, operating pressure and temperature history, material of construction, nominal thicknesses, service, heat treatment, etc.).

- Determination of the Maximum Permissible Working Pressure (PMTP) and the minimum thicknesses required for each equipment component.

- Estimation of wear rate and Remaining Life Time.

- Evaluation of the discontinuities reported (provided they are correctly dimensioned) during the inspections carried out on the equipment.

- If required, repair alternatives are issued for each anomaly (repair, rehabilitation, replacement).

- Establishment of the maximum inspection interval in accordance with the results of the evaluation, the provisions of the applicable regulations and the national legislation in force.

In conclusion, the mechanical integrity evaluation allows determining the fitness for service of the equipment based on its current condition, ensuring integrity and reliability until the next inspection period.

Risk based inspection (RBI)

The methodology of Risk-Based Inspection (RBI) is based on API 580, API 581, DNV-RP-G101 and ASME PPC-3 standards, through the quantitative determination of the estimated failure probabilities for each damage mechanism and considering the effectiveness of the prevention and/or control methods, as well as the quantitative estimation of the failure consequences. The purpose of the above is to determine the quantitative risk level, derived from the combination of the failure probability and the estimated consequence.

During the application of the RBI methodology, the following steps are followed:

- Review, classification of the information and preparation of the database with all relevant information on the equipment: design and construction, operational context, and inspection and maintenance history.

- Determination of the probability of failure for the identified damage mechanisms that may be present in each component and the cause that originates them. Damage identified during an in-service inspection may be the result of a pre-existing condition (i.e., prior to entering service) or service-induced.

- Determination of the consequence to classify the equipment based on the impact that can be generated by the type of failure caused by the identified mechanisms.

- Determination of the risk level using the API 581 matrix (5 x 5) or the one indicated by the Client, considering the probability of failure and the estimated consequences, based on the failure mode according to the identified damage mechanism.

- Determination of optimal inspection plan frequencies. Once the risk level is defined, the inspection plan is determined with frequencies (in order to optimize resources) with focused inspection activities (what, how, when and where to inspect).

- Risk mitigation actions. If necessary and in order to prevent, detect or minimize the consequences of undesirable events, actions are recommended to maintain the risk at levels tolerable by the organization.

In conclusion, the RBI allows prioritizing maintenance activities based on the level of risk, optimizing resources by focusing inspections on critical equipment or areas.

Strategic decision making

Based on the combined results of the FFS assessment and RBI analysis, the operator can make strategic decisions on inspection deferral, ensuring proper maintenance management based on the risk level and mechanical integrity condition of the equipment. This contributes to the effective implementation of a process safety system.

This article was developed by Penspen and published as part of the fourth edition of Inspenet Brief magazine December 2024, dedicated to technical content in the energy and industrial sector.