Guided Ultrasonics Limited (GUL) has been at the forefront of the industry of Non Destructive Testing (NDT) for 25 years, offering state-of-the-art solutions and revolutionizing the field with innovative technology. In this exclusive interview, Inspenet speaks with Dr. David Alleyne, CEO and co-founder of GUL, to discuss the company’s journey, its approach to innovation, and its vision for the future of the industry.

Inspenet (I): GUL has been an industry leader for 25 years. What are some of the milestones that have marked the company’s trajectory?

Dr. David Alleyne (DA): I think what has shaped us the most is the response we’ve received from the industry: the enthusiasm of our customers and the dedication of the people who have worked with us. It’s about feeling that we ‘re really contributing to solving the challenges facing the industry. That sense of contribution, over time, has motivated and encouraged us to do more and continuously improve.

I: Some companies in the Non-Destructive Testing sector have been around for almost a century. How do you envision the next 75 years for GUL?

DA: I’m old enough to know that I won’t see the next 75 years, but I hope to witness a significant part of that future. Innovation is central to the longevity of any company. For us, it’s about creating solutions to today’s problems, making those solutions more efficient and being prepared for challenges that have not yet arisen. Our goal is to innovate in response to the ways of working that are yet to come, helping our clients become more efficient, profitable and successful. Through their success, comes our own.

I: The energy sector is undergoing major changes, how is GUL adapting to offer the solutions required by the sector?

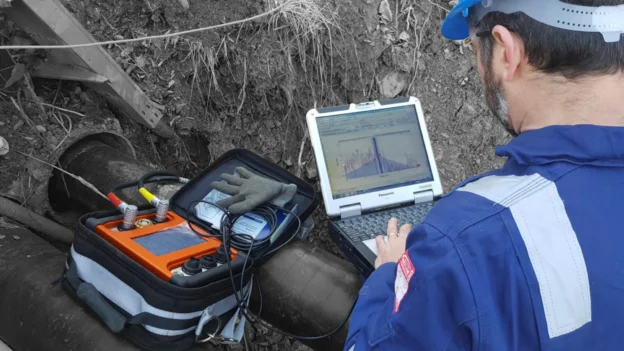

DA: The energy sector is evolving significantly, from the basis of what energy is to how it is distributed and managed. One of the areas we are focusing on is monitoring, which is reshaping our industry. We are focusing more on asset monitoring. Instead of reacting to problems like damage and corrosion, we are helping the industry anticipate them. By providing information such as, “This is happening, this is how fast it’s happening,” we provide the data needed to predict problems and enable more controlled and efficient asset management.

While we continue to develop and manufacture inspection equipment, we are increasingly offering monitoring equipment and, more importantly, global monitoring solutions that integrate technologies such as artificial intelligence, machine learning and automation.

I: We also want to ask you about managing a company in this sector. Can you share specific challenges the company has faced and how you have overcome them?

DA: We face many challenges, and they are part of the satisfaction of running a company. For us, improving communication, both within the company and with customers, has been a key challenge. How did we overcome it? Through technology. The pandemic taught us how to use technology to meet and generate interest remotely, and we have applied those lessons to improve communication with colleagues and the industry.

We understand that the measure of our success is not just what we sell, but how quickly we innovate technology. It’s also about listening to our customers to understand how to implement technology effectively and understanding their needs to define our next steps. It all comes down to communication.

I: What specific goals do you have for the next five years? And longer term, in 8 or 10 years? What would you like to see happen?

DA: I would like to see the expansion of this exciting new market of what I call real-time large area monitoring. This monitoring encompasses corrosion under insulation (CUI), midstream jetty lines, buried and aboveground pipelines, and process pipelines. The area of automation for monitoring is very exciting. We are achieving 10 times more efficiency and sensitivity, and getting real-time information about when corrosion or other types of damage starts, its growth rate and its causes. It’s really exciting to lead this new technological frontier, similar to when we introduced guided-wave pipeline screening 25 years ago.

I: What new NDT solutions do you have planned for the future? How will they improve safety and efficiency in the industry?

DA: We are focusing on artificial intelligence and machine learning. These technologies are already integrated into current inspection products, such as QSR, and are being expanded for use with Wavemaker. It’s all about helping inspectors do more in the time they have. The data can be reviewed by both people and automated machine learning systems. We also focus on connectivity, allowing data to be instantly reviewed by a Level 2 or Level 3 inspector from a remote location or analyzed automatically. It’s all about digitization and communication for a seamless flow of data and information.

I: David, one last question: Do you have a message for your employees, partners and customers?

DA: Thank you for your support. Thank you for trusting us. We value that trust. Our success is backed by people who are passionate about our technology. We specialize in guided waves and have world experts in this area. Over the past 30 years, we have been the innovators in this technology, introducing new tools such as Wavemaker inspection, gPIMS Monitoring and QSR scanning. Your support has enabled GUL to reach this 25-year milestone, and you can be absolutely certain that we are committed to improving and delivering even better technology for the next 25 years, ensuring that our reliability and commitment remain unmatched.

I: Dr. David Alleyne of Guided Ultrasonics Limited, thank you very much for this special interview.

DA: Many thanks to Inspenet for making this possible, for the fantastic communication, for their commitment to our industry and for spreading the word about the work of those of us who really want to push our industry forward and have the ambition to take it to new levels. With a constant focus on innovation, GUL continues to lead the NDT sector, pushing boundaries and preparing for a promising future.

This article was developed by the specialists at Guided Ultrasonics Limited and published as part of the fourth edition of Inspenet Brief magazine December 2024, dedicated to technical content in the energy and industrial sector.