TotalEnergies will supply 800 GWh of electricity with Clean Firm Power technology for SWM.

Pioneering renewable energy contract with constant delivery profile sets new standard for energy-intensive paper industry in Europe

He has more than 40 years in the oil and gas industry and is an expert in Level I Ultrasonic maintenance and inspection. His commitment to excellence ensures the reliability of critical equipment. He stands out for his vast experience, comprehensive understanding of methodologies and adaptability to new technologies.

Pioneering renewable energy contract with constant delivery profile sets new standard for energy-intensive paper industry in Europe

Diesel exhaust fluid (DEF) optimizes SCR systems, reducing NOx emissions while ensuring catalyst protection and efficiency.

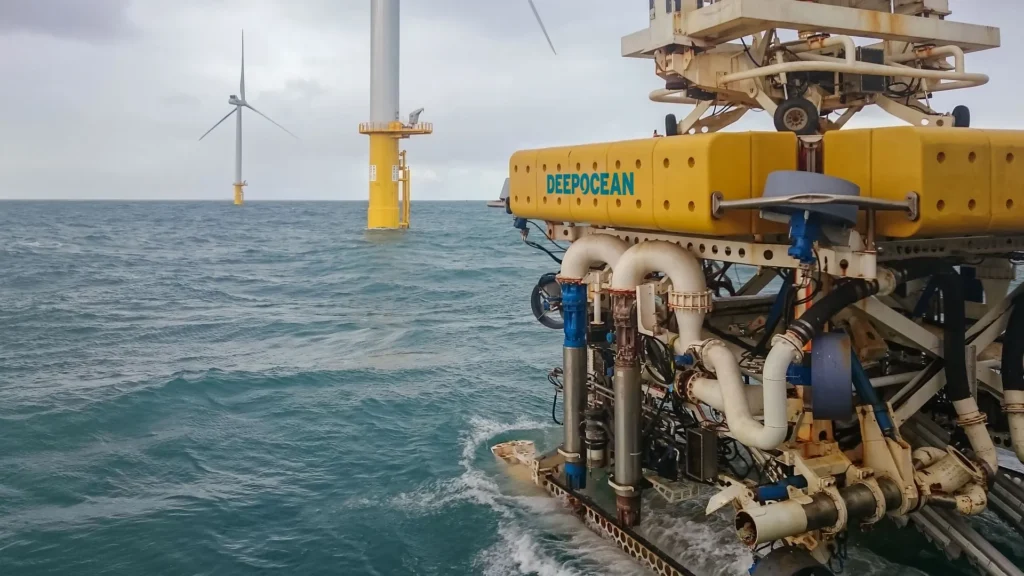

Norwegian company completes excavation and protection of submarine cables for U.S. offshore wind farm with advanced technology

The correct application of API 520 is critical to ensure the protection of pressurized equipment against overpressure scenarios.

In Davos, EDP supports the IETI's call to accelerate the energy transition and reindustrialize Iberia as a competitive engine for Europe.

Energy Fuels announced the acquisition of ASM for US$299 million to build the largest integrated rare earths chain outside China.

Offshore drilling company Seadrill Limited has announced the award of contracts for its West Capella, West Elara and West Carina vessels.

Harold Hamm suspends drilling in Bakken due to low oil profitability, a historic change for U.S. fracking.

The expansion of the Southern Gas Corridor brings the number of buyer countries to 16 and strengthens Azerbaijan's role as a reliable energy supplier in Europe.

Fire protection systems incorporate integrated components to detect fires as quickly as possible.

Energy for AI introduces an intense, concentrated, and continuous demand that redefines the rules of the game.

Gas production, operating efficiency and focus on LNG outline the Lower 48's upstream strategy in the face of lower oil activity.