Table of Contents

- Did you know that a bad weld can shut down a refinery?

- Types of welding: a strategic vision in engineering

- Electrodes: Key to weld bead quality

- Welding Procedure Specification (WPS) for integrity

- Welding procedures and qualification (PQR and WPQ)

- Weld Inspection: The Shield of Operational Reliability

- Non Destructive Testing (NDT) applied to welds

- Regulations: The global framework for integrity in welding

- Conclusion

- References

- FAQs on welding and inspection ASTM 2025

IIn the energy industry, welding and inspection are not just techniques; they represent the safety, productivity, and longevity of multimillion-dollar assets. From Pemex pipelines to offshore systems in the North Sea, every weld bead is a promise of operational integrity. “With a global welding cable market valued at USD 9,678.4 million in 2018 and projected to reach USD 21,260.7 million by 2032, the economic magnitude of this industry is undeniable”.1

In a context of constant technological evolution, where leading events such as FABTECH set the standard for innovations in manufacturing, welding, and metals, a deep understanding of these processes is more crucial than ever.

Did you know that a bad weld can shut down a refinery?

In this sector, welding is not just a task; it is often the critical path in the schedules of gigantic projects. A simple delay in a welding phase during transcontinental pipeline laying, or in a major plant shutdown (turnaround or scheduled shutdown) at a mega-refinery in Saudi Arabia such as Ras Tanura, in ambitious modernization projects at Pemex in Mexico, or at key refineries in Argentina, can translate into millions in losses and unacceptable risks to safety and the environment.

Essentially, welding is the process of joining two or more pieces of material, usually metals, by applying heat, pressure, or a combination of both, with or without the use of filler material (such as a welding rod), to achieve coalescence at the atomic level. It is the science and art of ensuring that the most vital components of our infrastructure remain joined, despite the most extreme conditions and operational challenges.

In this context of complex systems, the definition of welding is often described as a system that integrates multiple essential factors: “Welding is said to be a system because it involves the elements of the system itself, namely the 5 Ms: manpower, materials, machines, environment, and written means (procedures). A satisfactory joint means that it must pass mechanical tests (tension and bending). The techniques are the different processes (SMAW, SAW, GTAW, etc.) used for the most convenient and favorable situation, making it the most economical, without neglecting safety.2“

Types of welding: a strategic vision in engineering

Welding encompasses a wide range of processes, each with specific applications, advantages, and challenges. Understanding their classifications is essential for selecting the optimal method based on the asset type, operating conditions, and current regulations. Types of welding include:

- Arc Welding (AW)

- SMAW (Shielded Metal Arc Welding): Also known as “stick welding,” ideal for maintenance and field repairs, using a welding machine and generating an arc from the current.

- GMAW (Gas Metal Arc Welding / MIG welding/MAG): High productivity in workshops and for manufacturing refinery components, using continuous wire and gas shielding. The MIG wire segment accounted for 50.5% of the global welding wire market share in 2018, highlighting its prevalence1.

- GTAW (Gas Tungsten Arc Welding / TIG Welding): Precision for alloys and stainless steel, ideal for impeccable finishes with a non-consumable tungsten electrode and inert gas.

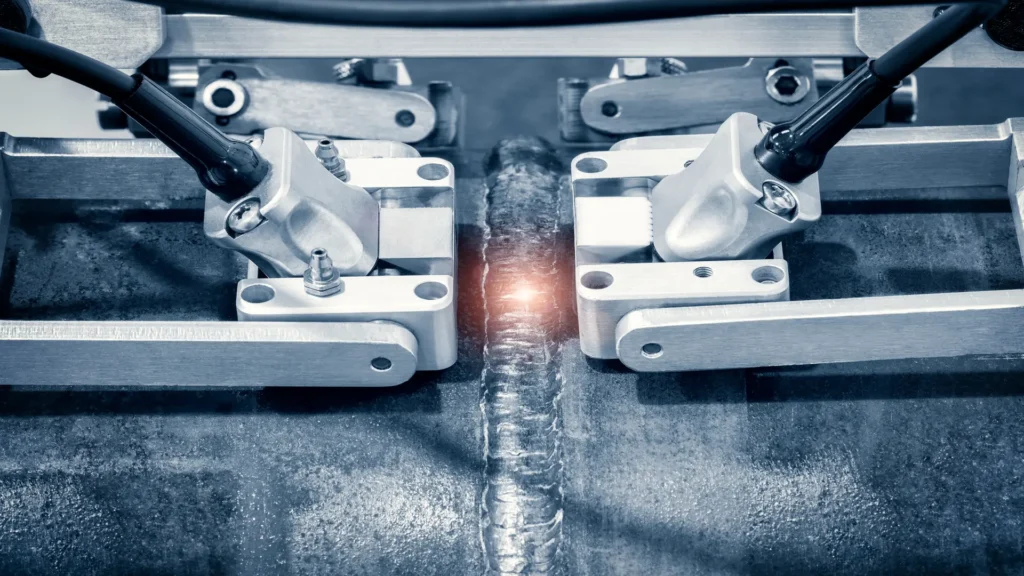

- SAW (Submerged Arc Welding): High efficiency for large thicknesses in large-diameter pipelines and tanks, with the arc submerged under a granular flux.

- FCAW (Flux-Cored Arc Welding): Versatility and high productivity outdoors, using a tubular wire with flux.

- PAW (Plasma Arc Welding): Controlled penetration and high quality in critical alloys, using a plasma jet.

- Gas Welding (GW)

- OAW (Oxyfuel Gas Welding): Fundamental for light repairs and metal cutting, through gas combustion.

- Resistance Welding (RW)

- Ideal for mass production, joining metals by electrical resistance and pressure: includes processes like spot welding, seam welding, projection welding, and flash welding.

- Solid-State Welding (SSW)

- FSW (Friction Stir Welding), friction, explosion, diffusion, ultrasonic: Joining without direct melting, where heat is generated by mechanical or chemical/physical means, key for dissimilar or sensitive materials.

- Energy Beam Welding (EBW & LBW)

- Maximum precision and minimal distortion: electron beam welding (EBW) and laser beam welding (LBW), using highly concentrated energy beams.

- Complementary Joining Processes

- Thermit Welding: Key alternative for joining large sections, like rails, through an exothermic chemical reaction.

- Brazing and Soldering: Key alternatives for lower-temperature joining with filler material, without melting the base material.

Electrodes: Key to weld bead quality

In the vast universe of welding, the welding wire is a general term encompassing the various metallic filler materials used in joining processes. These wires, including Metal Inert Gas (MIG) wire, Tungsten Inert Gas (TIG) wire, and other variants (such as SMAW covered electrodes or wires for SAW and FCAW), are fundamental to the formation of the weld and come in different forms and compositions, adapting to the process and base material. The global market is a key indicator of the health of the welding industry.

The selection of the electrode or welding wire defines the strength, toughness, and lifespan of the weld bead. The AWS (E XXYZ) classification guides this technical decision:

- E: Indicates that it is an electrode for arc welding.

- XX (or XXX): Represents the minimum tensile strength of the deposited metal (in thousands of pounds per square inch or ksi).

- Y: Indicates the welding position in which the electrode can be used (1: all positions, 2: flat and horizontal, 4: flat, horizontal, vertical down, and overhead).

- Z: Indicates the type of coating and current, influencing the properties of the deposit and penetration.

Types of electrodes according to their coating: Classification Z

- Cellulosic Electrodes (e.g., E6010, E6011): Deep penetration, ideal for pipelines and root passes, crucial for field repairs in gas pipeline networks in Mexico’s Pemex.

- Rutile Electrodes (e.g., E6013): Clean finish, smooth arc, versatile in the workshop.

- Basic Electrodes (e.g., E7018): Low hydrogen, high mechanical strength, extensive use in refineries and critical offshore structures like those in the North Sea, and components of Repsol or Pemex.

- Special alloys: For stainless steels, nickel, aluminum, and low-alloy steels under critical conditions. It is crucial to control toxic fumes when welding stainless steel (hexavalent chromium) with good ventilation and PPE, an indispensable welding best practice for welder safety.

Electrodes for alloys: precision in materials

When working with advanced alloys, electrode selection is a high-level engineering decision. The chemical composition of the filler material must be compatible and often nearly identical to that of the base metal to ensure desired mechanical properties and corrosion resistance.

- Stainless Steel Electrodes (e.g., E308L-16, E316L-16, E347-16 – AWS A5.4 Series): Designed to weld various grades of stainless steels. The “L” indicates low carbon, vital for minimizing sensitization in highly corrosive environments, such as gas processing plants and refineries. Important: “what toxic substance is released when welding stainless steel?”. The welding of stainless steels can generate fumes with hexavalent chromium (a carcinogen). Ventilation and PPE are indispensable welding best practices for welder safety.

- Low-Alloy Steel Electrodes (e.g., E7018-A1, E8018-B2 – AWS A5.5 Series): Contain alloying elements to match mechanical properties and resistance to creep or low temperature. Indispensable in the construction and repair of thick-walled pressure vessels, high-temperature piping, boilers, and critical components of power plants under severe conditions.

- Nickel Alloy Electrodes (e.g., ENiCrMo-3, ENiCu-7 – AWS A5.11 Series): Formulated to weld nickel alloys. They offer exceptional corrosion resistance in aggressive environments (acids, caustics) and at high temperatures. Critical in chemical processing plants and reactor components.

- Aluminum Alloy Electrodes (e.g., E4043, E5356 – AWS A5.3 Series): Designed for welding aluminum alloys. Relevant in cryogenic storage tanks (for LNG) and lightweight structural components in new energy sectors, where lightness and corrosion resistance are crucial.

Welding Procedure Specification (WPS) for integrity

In welding engineering, the Welding Procedure Specification (WPS) is a fundamental technical document that details all the variables and parameters necessary to produce a quality, repeatable weld. It is not simply a guide, but an unavoidable requirement to guarantee the integrity and safety of welded joints on critical assets. For highly demanding projects, such as the fabrication or modification of pressure vessels and pipelines, it is essential that the Welding Procedure Specification (WPS) is meticulously defined, qualified, and documented before any work begins.

A WPS is the detailed plan that a welder or welding machine operator must follow. Its purpose is to ensure that a welded joint meets the requirements of the applicable code or standard and possesses the desired mechanical and metallurgical properties for the service to which it will be exposed.

Key elements of a WPS

A typical WPS, governed by codes such as ASME BPVC Section IX or API 1104, contains detailed information on:

- Welding Process: The method or methods to be used (e.g., SMAW, GTAW, SAW).

- Base Material: Type, grade, P-number (for ASME), thickness or range of thicknesses.

- Filler Material: AWS classification of the electrode or wire, diameter, F-number (for ASME).

- Electrical Parameters: Current type (AC/DC), polarity, amperage, voltage.

- Gas Parameters: Type of shielding gas, flow rate (for GMAW, GTAW, FCAW-G).

- Joint Preparation: Joint type (butt, fillet), bevel design, fit-up.

- Weld Passes: Number of passes, pass technique (stringer or weaving), sequence.

- Welding Position: Permitted positions for which the procedure is qualified. This is a critical variable that directly influences the welder’s ability to execute the joint.

- Preheating and Interpass Temperature: Minimum and maximum temperatures required before and between welding passes, essential to prevent hydrogen cracking in alloy steels.

- Post-Weld Heat Treatment (PWHT): Requirements for temperature, time, and cooling rate, fundamental for relieving residual stresses and improving toughness.

Welding procedures and qualification (PQR and WPQ)

The validity of a WPS is established through a Procedure Qualification Record (PQR). The PQR is a record of the variables used during the welding of a test coupon and of the results of the destructive tests (tensile, bend, impact, hardness) performed on that coupon. If the results comply with the code, the WPS is considered qualified.

Once a WPS is qualified, welders and welding machine operators must be qualified to work under that procedure. This is done through a Welder Performance Qualification (WPQ), which evaluates the welder’s ability to deposit sound weld metal following a qualified WPS.

Strict adherence to a qualified WPS is a pillar of asset integrity, ensuring quality, reliability, and regulatory compliance in every welded joint of a project.

Weld Inspection: The Shield of Operational Reliability

Weld inspection is an irreplaceable pillar of mechanical integrity and operational reliability in the global energy sector. Its purpose is to ensure that welded joints comply with the most stringent codes, standards, and design specifications, and are free from discontinuities that could compromise their performance or safety. Organizations such as the American Society for Nondestructive Testing (ASNT) are fundamental in the standardization and advancement of the technologies that are applied. For this, we apply both non-destructive testing (NDT) or non-destructive examination (NDE) and, in specific cases, destructive testing.

Non Destructive Testing (NDT) applied to welds

These methods allow us to evaluate the integrity of the weld without damaging the part. Their selection is an engineering decision based on the material, thickness, geometry, the nature of the discontinuity sought, and strict regulatory requirements (e.g., API, ASME, NACE, NOM standards in Mexico, UNE standards in Spain).

1. Visual Testing (VT): The most fundamental and cost-effective method, performed before, during, and after welding. A certified and experienced weld inspector evaluates the weld surface for visible discontinuities such as cracks, porosity, undercuts. It is the first line of defense. API 653, API 570, and API 510 emphasize its critical importance in tank inspection, pipeline inspection, and pressure vessel inspection, respectively.

2. Liquid Penetrant Testing (PT): Detects surface discontinuities open to the surface. A liquid is applied that is absorbed by the defects, then a developer extracts them and makes them visible. Ideal for complex weld geometries or non-ferromagnetic materials such as stainless steel in petrochemical plants.

3. Magnetic Particle Testing (MT): Detects surface and subsurface discontinuities in ferromagnetic materials. A magnetic field is induced and particles cluster at the flux leaks caused by the defects. Very effective for detecting fine cracks in offshore structural weld beads.

4. Ultrasonic Testing (UT): It uses high-frequency sound waves. Upon finding an internal defect, part of the energy is reflected. With advanced techniques such as Phased Array UT (PAUT) and Time-of-Flight Diffraction (TOFD), a detailed image of the discontinuities and their location is obtained. It is a powerful tool for detecting internal defects such as lack of fusion or slag inclusions in thick welds in pipelines and pressure vessels. ASME and API standards validate its use.

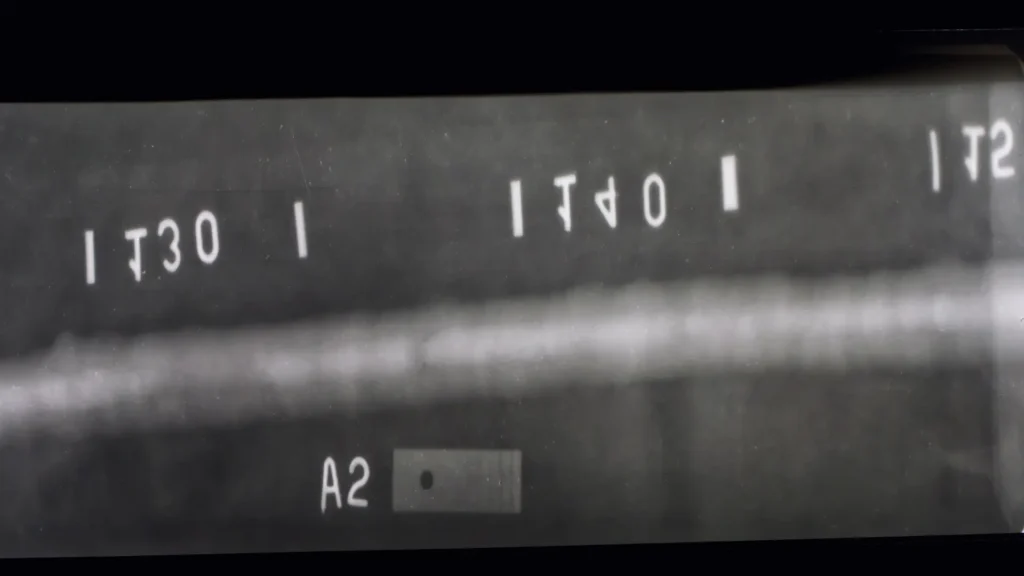

5. Radiographic Testing (RT): Uses X-rays or gamma rays to obtain an image of the internal density of the weld on a film or digital detector. Internal discontinuities (porosity, slag inclusions, lack of penetration) appear as density variations. It is a standard method for welder qualification and critical weld inspection in pipelines and pressure vessels.

Regulations: The global framework for integrity in welding

The rigor of welding inspections is dictated by a series of international codes and standards, which are essential for the safety and uninterrupted operation of energy facilities.

- API (American Petroleum Institute): For pressure vessels (API 510), pipelines (API 570), and tanks (API 653), as well as pipeline welding (API 1104).

- ASME (American Society of Mechanical Engineers): Its codes, such as the ASME Boiler and Pressure Vessel Code (BPVC), are the global standard for the design, manufacture, and inspection of boilers and pressure vessels. Section V (Non-Destructive Testing) and Section IX (Welding and Welder Qualification) are required reading for any engineer in the industry working on large-scale projects. It is important to note that ASME Section IX provides the rules for WPS and WPQ qualification.

- AWS (American Welding Society): Establishes standards for welder qualification, procedures, and various welding processes (e.g., AWS D1.1 for structural steel).

- NACE International: Crucial for corrosion control and material selection (e.g., NACE MR0175/ISO 15156).

- ISO (International Organization for Standardization): Standards like ISO 9712 (NDT personnel qualification) and ISO 3834 (quality requirements for welding).

- Local standards: Such as NOM (Official Mexican Standards) and UNE (Spanish Standard).

Conclusion

Welding and inspection are critical processes in materials engineering and industrial asset management. Proper consumable selection, welding procedure specification (WPS) validation, and non-destructive testing (NDT) in accordance with international codes and standards ensure compliance with design and performance requirements. Technical discussions at international forums such as FABTECH 2025 and the ASNT Annual Meeting highlight the convergence between technological innovation and industrial practice, driving the development of automated solutions and advanced systems.

References

- Fortune Business Insights. “Welding Wires Market.” Fortune Business Insights, https://www.fortunebusinessinsights.com/en/industry-reports/welding-wires-market-101597 (Accessed: July 26, 2025).

- “Welding.” Wikipedia, The Free Encyclopedia, https://en.wikipedia.org/wiki/Welding (Accessed: July 13, 2025).

FAQs on welding and inspection ASTM 2025

How relevant is the ASTM 2025 event for weld inspection?

The ASTM 2025 meeting updates standards and testing methods applicable to welding and NDT. Its decisions directly impact WPS/PQR procedures and quality requirements in energy projects.

What must a company guarantee in order to comply with ASTM welding standards?

It must qualify procedures (WPS/PQR), certify inspectors according to ASNT/ISO, apply NDT in accordance with the standard, and maintain full traceability of materials, welders, and reports.