X-ray Diffraction is a scientific technique used to evaluate the internal structure of materials. It is based on the phenomenon of the interference of X-ray waves when they impinge on a crystalline sample. This technique has proven to be especially valuable in characterizing the crystalline structure of various materials, including those used in hydroelectric plants.

Although it is a little-known technique, its ability to reveal details of the atomic and molecular structures of materials makes X-ray diffraction a very useful tool to assess the quality, safety, and efficiency of such materials.

Basic principles of X-ray Diffraction

X-ray Diffraction is a technique that is based on the principle of constructive interference of X-ray waves when interacting with a sample. When X-rays strike a crystalline material, the atoms scatter the radiation in different directions, creating a characteristic diffraction pattern. This pattern contains important information about the arrangement of atoms in the crystal structure and the distances between them.

X-Ray Diffraction Tests (XRD)

It is a non-destructive testing method for the determination of residual stress in polycrystalline materials. Stress, induced by heat treatment or machining, for example, can build up over the life of the material and cause unexpected failure of equipment or piping in a Hydro Power Plant. The control of residual stress, therefore, is essential to improve the safety and durability of a material.

Applications in hydroelectric plants

In the context of this type of plants, X-ray diffraction tests are especially useful to evaluate the residual stresses present in the materials used in their construction. These stresses can arise during the manufacturing process or due to the load and continuous operation of the plant. If not properly detected and controlled, residual stresses can compromise the structural integrity of materials, which could lead to catastrophic failures and endanger the safety of the plant and those close to it.

X-ray diffraction residual stress (XRD) analysis can be applied to a wide variety of polycrystalline materials, such as hardened steel, welded joints, or ceramics. It is used as a quality control tool, as well as in academic and industrial research.

With X-ray Diffraction (XRD) , residual stress near the surface is investigated, typically to a depth of a few microns. Films and coatings with a thickness of submicrons can also be investigated using a friction impingement geometry. This technique also allows the elaboration of depth profiles.

Some of the key applications of X-ray diffraction in hydropower plants include:

- Characterization of structural materials

X-Ray Diffraction is used to analyze the crystalline structure of materials used in hydroelectric plants, among others. This allows determining the quality of the material, identifying defects in the crystalline structure and evaluating its mechanical resistance. For example, when analyzing the concrete used in the construction of dams, it is possible to detect the formation of undesirable phases or the deterioration of the structure due to prolonged exposure to water.

- QA

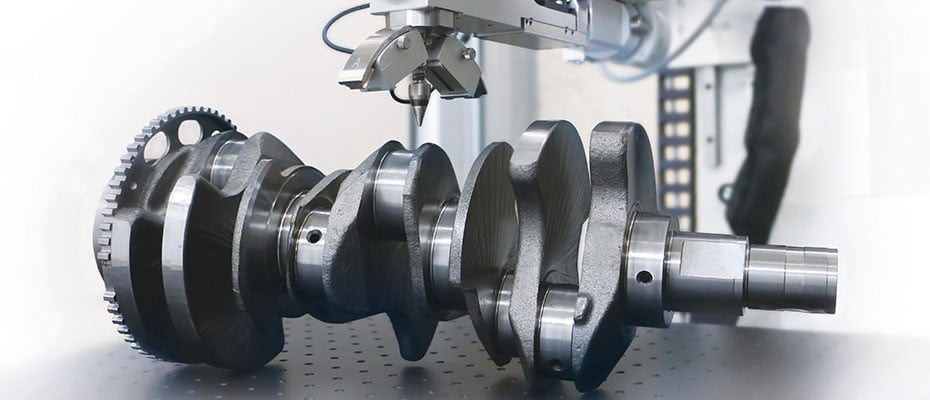

This technique is used for quality control of surface treatments on different types of components such as gears, crankshafts and turbine blades.

- Residual stress analysis

X-ray diffraction is also used to measure residual stresses in the structural materials of hydroelectric plants. These stresses can be generated during the manufacturing process, cooling, or due to external loads. Knowledge of residual stresses is essential to prevent structural failures and guarantee the safety of the facilities. X-ray diffraction makes it possible to measure deformations in the crystalline structure of materials and to calculate the corresponding stresses.

- Identification of crystalline phases

In hydroelectric plants, it is essential to know the crystalline phases present in the materials used, since this can affect their mechanical behavior and their resistance to corrosion. X-ray diffraction makes it possible to identify the crystalline phases present in a sample, which helps to better understand the physical and chemical properties of the materials used.

Stress analysis of a crankshaft with X-Ray Diffraction , Source https://test-systems.es/difraccion-de-rayos-x/

Benefits of the application of X-ray diffraction

The application of X-ray diffraction in hydroelectric plants offers several significant benefits, including:

- Security enhancement

By evaluating the internal structure of materials, this technique can detect defects and residual stresses that could lead to catastrophic failure. This contributes to improving the safety of hydroelectric plants and reduces the risk of accidents or collapses.

- Increased efficiency

By better understanding the crystalline structure of the materials used, it is possible to select more suitable materials and design more efficient components in hydroelectric plants. This can result in greater energy efficiency and reduced operating costs.

- Maintenance optimization

It is used to monitor the degradation of materials in hydroelectric plants over time. This makes it possible to schedule maintenance interventions proactively, avoiding unplanned stops and optimizing maintenance intervals.

Advantages and Disadvantages of the Technique

Advantages of the technique

- It is non-destructive.

- Applicable in laboratory or in situ.

- Perform biaxial residual stress measurements.

- Excellent for measuring surface tension gradients.

- Large magnitude residual stresses are accurately measured.

- Complex shapes can be tested

- Very quick and easy to apply.

- Measurement of macro and micro tensions.

Disadvantages of the technique

- Measuring depths are only 10-20 μm as standard, without electropolishing.

- Only applicable to polycrystalline materials.

- Accuracy seriously affected by grain size and texture.

- Requires a good surface finish.

Conclusions

X-ray diffraction tests represent a very versatile, reliable and little-known tool to evaluate residual stresses in hydroelectric plant materials. By analyzing diffraction patterns, it is possible to reveal the internal structure of materials and detect hidden stresses that could compromise the safety and efficiency of these infrastructures.

The application of this technology in hydroelectric plants offers significant benefits, including improved safety, optimization of manufacturing processes, and reduced maintenance costs. It is essential that professionals in this field become aware of the usefulness of X-ray diffraction tests and consider them as a valuable alternative to guarantee the optimal operation of hydroelectric plants in the future.