Welding, widely used in manufacturing and industrial maintenance, has progressed with the objective of optimizing the strength, precision and efficiency of joints. Today, technological advances have transformed both traditional processes and modern techniques, integrating automation, computer simulation, new energy sources and intelligent welding equipment.

This article analyzes the main types of welding and the technical innovations applied in processes and equipment, addressing how these transformations contribute to improve operational efficiency, traceability and structural quality in modern industry.

Importance of innovation in welding processes

In modern industrial manufacturing, welding is no longer an isolated manual operation but a strategic manufacturing process. Technical innovation in both welding processes and welding equipment has been consolidated to meet requirements for productivity, adaptation to new materials, defect reduction and regulatory compliance.

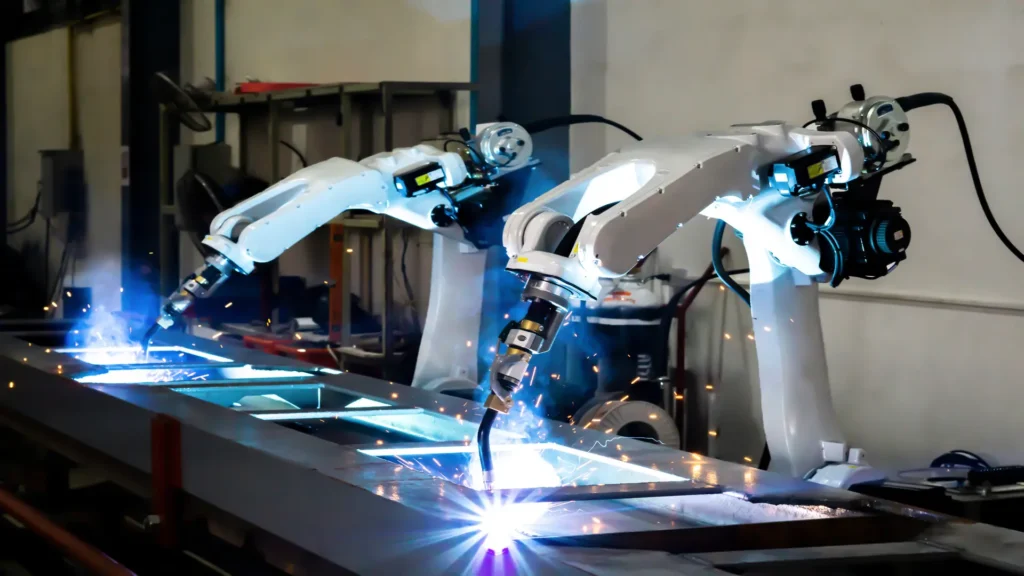

State-of-the-art equipment – from multiprocess power sources to intelligent torches, robotic heads and digital power systems – incorporates features to configure and control parameters in real time. The integration of advanced sensors, CNC controls, IoT connectivity and programmable interfaces has elevated welding to a new level of precision, safety and repeatability within the specialized technical industry.

Technical classification of welding types

Industrial welding is classified into five major technical categories, depending on the physical principle that generates the joint: electric arc welding, gas welding, resistance welding, energy beam welding and solid state welding. The most representative types in each group are described below:

Electric arc welding

It is based on the formation of an electric arc between an electrode and the base piece, which generates the heat necessary to melt the metals and form the joint. Electric arc welding is the most widely used family globally.

- SMAW (Shielded Metal Arc Welding) or coated electrode: It employs a consumable electrode with a flux coating that protects the molten pool. It is portable and widely used in construction and maintenance.

- GMAW (Gas Metal Arc Welding) or MAG / MIG welding: Employs a continuous electrode wire and shielding gas (inert for MIG, active for MAG). It is versatile, automatable and common in the automotive industry.

- FCAW (Flux-Cored Arc Welding): Similar to GMAW, but the wire contains internal flux. May or may not require external gas. Used for high deposition welds.

- GTAW (Gas Tungsten Arc Welding) or TIG welding: Uses a non-consumable tungsten electrode and inert gas (argon or helium). Ideal for precision welding of stainless steels, light alloys and reactive metals.

- SAW (Submerged Arc Welding): Produces the arc under a bed of granular flux. It offers high penetration, minimum radiation and excellent performance in joints.

Gas welding

Uses the thermal energy of a flame generated by the combustion of combustible gases (such as acetylene) with oxygen.

- Oxyacetylene welding: employs an oxyacetylene flame to melt the base metal and filler material. Although displaced by electrical methods, it is still useful in repairs, cutting and fine welding.

Resistance welding

It is based on the heat generated by the electrical resistance to the passage of current, combined with mechanical pressure to achieve the joint; it does not require filler material or shielding gas.

- Spot welding (RSW): Joins overlapping metal sheets by means of electrodes. Most commonly used in automotive bodies.

- Resistance spot welding (RSEW) or seam welding: Generates continuous beads by means of conductive rollers. Ideal in packaging and hermetic structures.

Energy beam welding

Uses high energy density beams to melt the base material with high precision and minimal HAZ (Heat Affected Zone).

- Electron beam welding (EBW): Performed in a vacuum with an accelerated electron beam, resulting in deeper, narrower, low-distortion welds. Used in aerospace, nuclear and medical devices.

- Laser beam welding (LBW): Employs a highly concentrated laser beam. Ideal for high speed, minimal ZAC and precision in steels, aluminum or electronics.

Solid-state welding

In these processes, the base material is not melted; heat and mechanical pressure generate the joint through controlled plastic deformation.

- Friction stir welding (FSW): A rotating tool plasticizes the edges without melting; widely used in aluminum, magnesium and aerospace or railway sectors.

- Rotary or linear friction: presses two parts in relative motion until the joining temperature is reached; common in shafts, gears and symmetrical elements.

- Ultrasonic welding: The joint is made by ultrasonic vibrations under pressure. It is used in thin films, copper, aluminum and electronic or biomedical applications.

Recent innovations in welding processes

Digital sources and advanced arc control modes

Advanced arc technologies have undergone a major development, with the use of digital multiprocess power sources, precisely modulating energy delivery according to the dynamic behavior of the arc. They control in real time variables such as voltage, current, arc length and wire speed, improving process repeatability and integrating with robots, cobots and automated cells.

Advanced operating modes such as Cold Metal Transfer (CMT), Surface Tension Transfer (STT) and pulse-on-pulse have optimized metal transfer in GMAW (MIG) processes; these modes offer a more stable arc, reduced spatter welding of galvanized or thin materials with greater thermal control, less distortion and better bead quality.

In the video below, Lincoln Electric demonstrates the use of the STT® Field mode in conjunction with the Activ8X Pipe® feeder, a specialized setup for root welding on pipe. It improves arc stability, optimizes penetration and reduces manual defects.

STT® field vs stick – root pass weld comparison.

Smart filler materials and shielding gases

The development of specialized consumables has optimized structural quality in different types of welding. Advanced compositions —such as microalloyed alloys, hybrid solid wires or consumables designed for pulsed processes— improve mechanical strength and corrosion resistance in conditions such as HIC, pitting or SSC. They also increase toughness and reduce defects during solidification.

In parallel, shielding gas mixtures have been formulated to stabilize the arc, control bead geometry and reduce the Heat Affected Zone (HAZ). Combinations of argon with CO₂, helium or hydrogen are adapted according to the type of transfer (pulse, CMT, spray), base material and thickness, achieving controlled melting and greater metallurgical uniformity.

Collaborative robotics and autonomous welding powered by AI

The incorporation of collaborative robots (cobots) has automated welding tasks in small parts, high precision processes or small batch production, with less integration complexity and affordable costs. They are integrated with 3D vision systems and laser sensors to adapt to variations in the position of the joint, correcting its trajectory and parameters in real time.

Welding cobots enable flexible automation, sensor integration and dynamic adaptation in high-precision tasks

Using autonomous welding, powered by artificial intelligence, the robots execute the welds, and optimize the process themselves. They detect in-line defects, adjust the trajectory and perform finishing tasks such as bead grinding with precision.

Recent advances include active vision sensors based on neuromorphic events, which mimic the human visual system to detect and anticipate changes in the weld pool, bead geometry and environment, enabling adaptive welds on deformed or misaligned parts without human intervention.

AI-assisted simulation and predictive modeling

Thermal simulation and computational modeling tools such as SYSWELD, Simufact Welding or ANSYS Mechanical Welding Suite can predict residual stresses, distortions, thermal distribution and microstructural evolution in complex welded joints.

The latest versions incorporate machine learning algorithms, automatically adjusting parameters such as energy input, feed rate or bead path according to the simulated results. This hybrid approach accelerates the validation of procedures, reduces the need for prototypes and is applied in sectors such as nuclear, oil & gas and aerospace.

TIP TIG welding and laser guidance of the arc

The TIP TIG process is an evolution of conventional TIG welding that introduces wire oscillation and modulated pulsed current. This technique improves deposition rate, reduces thermal input and is ideal for alloys such as Inconel, Hastelloy and titanium used in pharmaceutical, aerospace and nuclear piping.

A case in point is the SWR TIP TIG® SWR system, shown in the following ABICOR BINZEL video, applied to automated orbital pipe welding. It combines thermal control, repeatability and high productivity in critical applications such as heat exchangers or pressure vessels.

Automated orbital welding with TIP TIG SWR® process

In addition, Laser Guided Arc Welding technology combines a laser beam with the MIG or TIG arc, stabilizing its trajectory, reducing the bead width and doubling the feed rate without loss of penetration. It is applied to thin sheets and complex fillets with automated visual assistance.

Intelligent quality control and welder assistance

Multimodal AI systems integrate thermal, acoustic and visual analysis to detect defects such as porosity, inclusions or lack of fusion in real time. This adaptive monitoring dynamically corrects parameters, ensuring quality in critical turbine, pressure vessel or offshore welds. In addition, by digitally validating bead integrity, the need for physical prototypes and nondestructive testing (NDT) is reduced, streamlining technical validation.

Augmented reality (AR) is also transforming welding training and support. By overlaying digital information on the physical environment, it guides trajectories, alerts on deviations and corrects errors in real time, reducing the learning curve, improving operational accuracy and strengthening traceability under Industry 4.0 standards.

Conclusions

Welding evolves at the pace of modern engineering advances. The different types of welding, from classical processes such as SMAW and TIG to state-of-the-art technologies such as FSW, laser or WAAM, each process has been refined to meet increasing technical demands.

The incorporation of intelligent power sources, innovative welding equipment, robotic heads, computational simulation and adaptive monitoring have optimized thermal efficiency, reduced defects and expanded application possibilities in complex geometries. Backed by international standards and digital traceability, welding remains a strategic process in advanced industrial manufacturing.

Welding processes are poised to lead advanced manufacturing in an environment of unprecedented digital, energy and structural demands.

References

- https://es.wikipedia.org/wiki/Soldadura

- https://eticampus.edu/welding-program/welding-training/different-types-of-welding/