Energy asset management integrates processes, people and technology to maximize performance, reliability and profitability throughout the lifecycle. In a process of transition and regulatory pressure, moving from reactive to proactive and predictive is key to process optimization, energy sustainability and economic efficiency.

This guide explains what EAM is, what energy assets it encompasses, what data analytics platforms and systems drive it (SCADA, CMMS/APM, EMS), how to implement it and what tangible benefits it brings. The objective is to provide practical criteria, comparisons and best practices for technical decisions.

What is energy asset management (EAM)?

EAM is a comprehensive system of governance, processes and data designed to plan, operate, maintain and retire assets, maximizing their value and minimizing risk throughout their entire life cycle. This strategic approach replaces the “fix it when it breaks” mentality with proactive and predictive data-driven strategies.

It is aligned with ISO 55000 and rests on three pillars: people, processes and technology. It uses risk models and key performance indicators (KPIs) such as availability and MTBF/MTTR (mean time between failures and mean time to repair) to orchestrate a digital ecosystem that enables verifiable decisions aligned with energy sustainability.

What are energy assets?

An energy asset is any physical asset, and its digital enabler, that produces, transforms, transports, stores, measures or controls energy. Its performance impacts the reliability, cost, compliance and sustainability of any operation.

Main types

- Generation: Gas/steam turbines, photovoltaic, wind, boilers, diesel units.

- Transformation: Transformers, inverters/rectifiers, heat exchangers, VFDs.

- Transmission and distribution: Lines and substations, pipelines, pump/gas pipelines, pump/compressor stations.

- Storage: BESS, storage tanks, LNG/LPG, hydrogen (tanks and pipelines).

- Measurement and control: Fiscal meters, chromatographs, SCADA, protections, IoT sensors.

- Energy intensive consumption: Furnaces, compressors, pumps, chillers, industrial HVAC.

Key technologies driving EAM

Energy asset management is driven by interconnected technologies that provide real-time data, automation and advanced analytics. These tools are critical for diagnosing asset condition, forecasting failures, and making informed decisions that balance performance, cost, risk, and sustainability.

SCADA and real-time monitoring

SCADA (Supervisory Control and Data Acquisition) systems are the “nervous system” of the operation. They collect and consolidate data from sensors and field equipment, generate early alarms and feed historians for trend and anomaly analysis. This continuous monitoring is the basis of an effective EAM, allowing proactive adjustments and better coordination with other systems.

CMMS, EAM and APM software

- A CMMS (Computerized Maintenance Management System) centralizes work orders, planning, inventories and traceability.

- EAM platforms extend this scope with a financial, compliance and full asset lifecycle view.

- The APM (Asset Performance Management) layer adds failure analytics, asset health modeling and risk-based maintenance prioritization (RCM/FMEA).

Together, this toolset integrates IoT/SCADA data, supports field mobility, and connects operational metrics with financial metrics to justify technical decisions with verifiable ROI.

Predictive and preventive maintenance

Predictive maintenance combines sensor data (vibration, temperature, ultrasound, thermography) with analytics and artificial intelligence to estimate degradation and time to failure. This approach complements preventive (time/usage-based) and condition-based maintenance (CBM), avoiding unexpected shutdowns and unnecessary interventions, extending asset life and stabilizing availability.

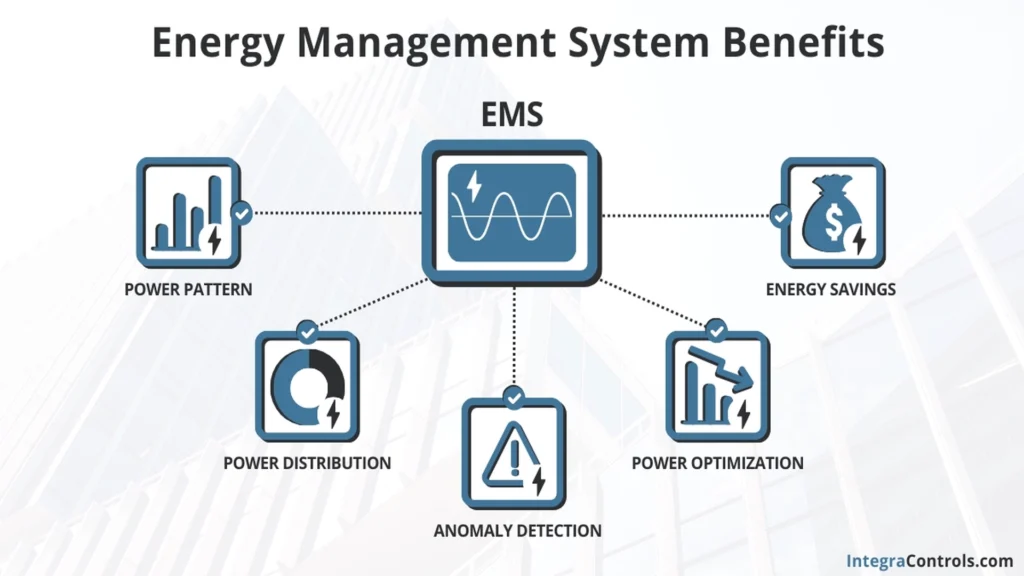

Energy Management Systems (EMS)

An EMS optimizes the balance between generation, storage and demand. It provides granular metering by zone and enables demand response. Integrated with EAM, it translates efficiency opportunities into action plans and measurable benefits, such as reduced consumption, emissions and costs.

Enabling digital assets

Data analytics platforms, SCADA/historian, CMMS/APM, EMS and digital twins provide the end-to-end traceability and operational-financial context needed for decision making. In modern architectures, they are supported by data lakes/BI, interoperability (OPC UA/API) and industrial cybersecurity (IEC 62443).

How to implement EAM in your organization

Implementing EAM is not just about installing software; it is about orchestrating people, processes and data to extract more value from assets. The key is to start with a defined scope, demonstrate early ROI and scale with an architecture that integrates SCADA, CMMS/APM, EMS and data analytics platforms. Here’s a practical path.

- Comprehensive asset evaluation: Before investing, know your asset pool. Build the catalog and hierarchy (plant → system → asset → component), and evaluate condition, failure modes and criticality (safety, environment, production, cost). Build a baseline of performance (availability, MTBF/MTTR), OPEX and energy consumption.

- Define goals and metrics: Connect business objectives to operational KPIs. For example: “Reduce unplanned downtime by 2%”, “reduce OPEX by 10%” or “improve energy intensity by 5%”. Set thresholds and dashboards to monitor progress.

- Select the technology: The goal is not “the most complete tool”, but the most integrable architecture. Choose an EAM/CMMS/APM system that communicates with your SCADA/IoT via APIs or OPC UA. Consider scalability, advanced analytics and data governance.

- Implement and train: Avoid the “big bang” approach. Implement a pilot in an area with critical assets and available data. Define success criteria, standardize procedures and train teams in the new processes and tools, not just in the use of the software.

- Integration and cybersecurity: Connecting SCADA, IoT, EAM, EMS and BI systems requires robust interoperability and strong industrial cybersecurity. Align policies with standards such as IEC 62443 to ensure data integrity, reliability and security.

- Continuous improvement: EAM is a maturing process. Establish regular review cycles, perform root cause analysis (RCA) for critical events and adjust predictive maintenance plans based on evidence. The ultimate goal is to create a data-driven decision culture.

Benefits: Sustainability, performance and costs

- Improved performance: higher asset availability and fewer unplanned shutdowns thanks to the transition from reactive to predictive, with optimized intervention windows and extended service life.

- Cost reduction: lower operating expenses (OPEX) due to optimized maintenance plans and reduced energy consumption. CAPEX is also deferred by extending the useful life of assets.

- Energy sustainability: increased efficiency and more effective integration of renewables, with clear traceability of emissions to meet ESG targets.

- Risk mitigation and compliance: Real-time monitoring, early warnings and criticality management reduce the likelihood of serious failures and penalties.

Comparisons and best practices

CMMS vs EMS

- CMMS: Focused on predictive maintenance, work order management, intervention scheduling and recurrent failure analysis, integrating IoT data for greater accuracy.

- EMS: Focused on global energy efficiency, consumption optimization and dynamic balance between generation, storage and demand, with the ability to report sustainability metrics in real time.

Selection criteria

- Scalability with asset portfolio.

- Integration with ERP, SCADA and IoT for a unified data source.

- Functionality: mobile access, robust reporting, dashboards, asset modeling/status.

International best practices

- ISO 55000 for asset management with a systematic approach.

- Integration of ESG KPIs in operational and strategic performance indicators.

- Use of digital twins for simulation, predictive modeling and risk scenario assessment.

Conclusions

The future of the energy sector is intrinsically linked to smart asset management, where energy asset management is not just a trend, it is a fundamental necessity for organizations seeking to improve reliability, profitability and long-term viability.

By integrating data analytics, SCADA, CMMS/APM and EMS platforms, companies can move from reactive to predictive management, raising the availability of their assets and reducing their risks and costs. With clear goals, data governance and a focus on continuous improvement, EAM aligns operations with financial and ESG objectives, preparing the organization for a more digital, efficient and sustainable future.

Frequently Asked Questions (FAQ) about EAM

What is the difference between EAM and CMMS?

EAM is a strategic approach that manages the entire asset lifecycle (planning, finance and risk), while CMMS focuses on maintenance tasks.

How does EAM help sustainability?

Optimizes energy use, reduces waste and efficiently manages renewable energy assets, improving energy sustainability.

What are the main challenges of implementing EAM?

Data quality assurance, systems integration, management support for staff training.