Table of Contents

- What type of compressor does API 617 govern?

- What type of compressor does API 617 cover?

- What types of compressors does API 619 cover?

- Design and construction: Conflicting Engineering Philosophie

- Maintenance of API 617 and API 619 compressors

- Which standard handles dirty gases better?

- Conclusions

- References

The American Petroleum Institute (API) has established a set of standards that regulate the design, construction, and performance of rotating equipment used in the oil and gas industry. These standards ensure the reliability, efficiency, and safety of equipment subjected to severe operating conditions, such as high pressures, elevated temperatures, and corrosive or contaminated gases.

In the case of compressors, API 617 and API 619 are the most representative standards. Each defines the minimum requirements for design, materials, testing, and maintenance for different types of equipment within the energy and industrial sectors.

What type of compressor does API 617 govern?

API 617 applies to centrifugal, axial, and mixed-flow compressors used in continuous service within refineries, petrochemical plants, gas pipelines, and natural gas processing systems. This equipment is designed to handle large gas flows at moderate or high pressures, maintaining stable and efficient operation over long periods.

Compressors under this standard are characterized by their high-precision construction, industrial-grade bearings and mechanical seals, and a modular configuration that facilitates maintenance and allows direct integration into compression trains alongside turbines or electric motors.

In terms of performance, API 617 compressors guarantee precise flow and pressure control, with superior volumetric efficiency and the ability to operate without interruption in critical applications where reliability is an essential parameter.

What type of compressor does API 617 cover?

The API 619 standard applies to positive displacement rotary compressors, mainly rotary screw, sliding vane, or roots type. This equipment is designed to handle dirty, wet, or high-particle-content gases, where centrifugal compressors are not suitable due to the risk of erosion or damage to the impellers.

Unlike API 617, API 619 compressors focus on delivering constant flow regardless of pressure, making them ideal for low to medium pressure services, process steam systems, waste gas recovery, instrument air, or high viscosity gases.

Their design incorporates wider tolerances and robust lubrication systems capable of protecting internal components from wear and contamination. In addition, API 619 compressors typically have lower maintenance costs and greater tolerance to variations in suction conditions.

What types of compressors does API 619 cover?

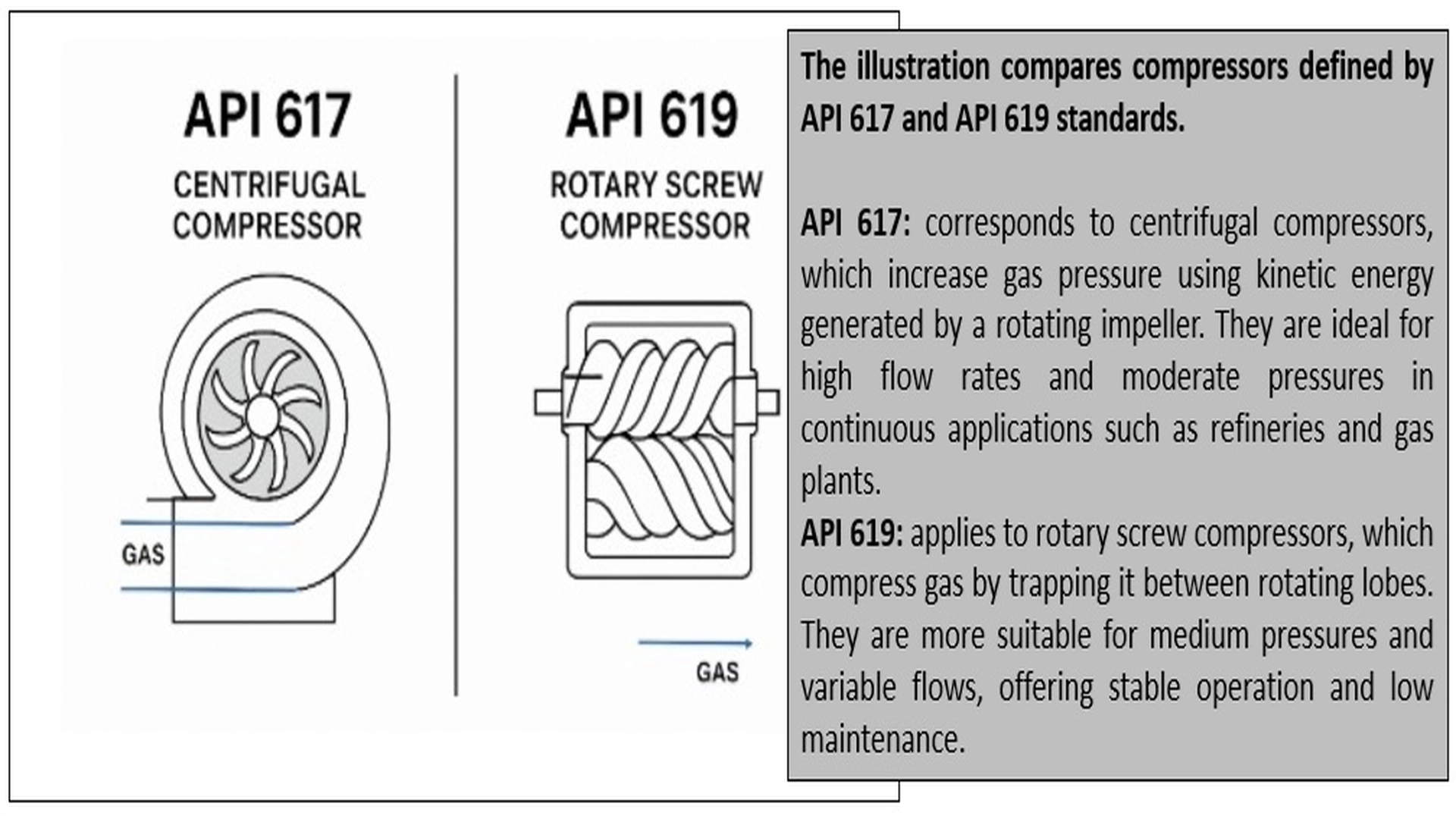

Although both standards belong to the API family of standards for rotating equipment, their technical application differs significantly:

API 617 defines the requirements for centrifugal compressors, whose operation depends on the conversion of kinetic energy into pressure energy. This equipment is suitable for clean, dry, non-corrosive gases and is notable for its ability to handle large volumes with high-energy efficiency.

In contrast, API 619 covers positive displacement rotary compressors, where compression is achieved by reducing the volume of gas within closed chambers. This design is more suitable for dirty or liquid-laden gases, as its operation is not affected by moderate impurities or condensates.

In summary, API 617 prioritizes efficiency and continuous performance, while API 619 focuses on robustness, ease of maintenance, and adaptability to adverse conditions.

Comparative table of technical differences between API 617 vs API 619

| Parameter | API 617 (Centrifugal) | API 619 (Positive Displacement Rotary) |

| Compressor type | Centrifugal, axial, or mixed flow | Screw, vanes, or rotary lobes |

| Operating principle | Conversion of kinetic energy to pressure | Volumetric gas reduction |

| Gas type | Clean and dry | Dirty, wet, or containing particles |

| Typical pressure | High to very high | Low to medium |

| Efficiency | High isentropic efficiency | Moderate efficiency |

| Maintenance | High precision, predictive | Frequent but simple |

| Applications | Gas pipelines, refineries, petrochemicals | Gas recovery, instrument air |

| Life cycle cost | High, associated with reliability | Moderate, with less complexity |

Design and construction: Conflicting Engineering Philosophie

The design of an API 617 compressor is based on fluid dynamics and three-dimensional aerodynamic analysis, seeking to maximize isentropic efficiency and reduce internal losses due to turbulence.

The impellers are precision balanced, made of high-strength materials such as stainless steel or nickel alloys, with dry gas seals to minimize leaks.

On the other hand, the API 619 design focuses on displacement mechanics. The screws, lobes, or vanes generate uniform compression, with hardened materials and surface treatments that improve durability against contaminated gases. The mechanical simplicity of this equipment facilitates its operation in remote environments and its repair in the field.

Maintenance of API 617 and API 619 compressors

The maintenance of API 617 compressors is highly specialized. It requires trained personnel for precise shaft alignment, bearing inspection, and gas seal calibration.

Any deviation in clearances or dynamic balance can lead to critical vibrations, overheating, or loss of efficiency. For this reason, predictive maintenance through vibration analysis, thermography, and condition monitoring is essential.

In contrast, API 619 compressors require more frequent but less complex maintenance. Routine tasks typically include inspecting rotors, checking the lubrication system, and servicing discharge valves.

Their more tolerant design allows for greater operational flexibility, although their energy efficiency tends to be lower compared to centrifugal equipment.

Which standard handles dirty gases better?

The choice between an API 617 or API 619 compressor depends on the type of gas, operating pressure, required flow rate, and environmental conditions. In dry gas services, with high efficiency and availability requirements, API 617 is the undisputed benchmark.

On the other hand, when the gas contains impurities or moisture, API 619 offers a more robust and reliable solution.

In modern petrochemical plants, both types of compressors often coexist: centrifugal compressors are used in main process stages and rotary compressors in auxiliary services or gas recovery systems.

Proper integration of both designs optimizes the overall performance of the facility and reduces operating costs.

Conclusions

API 617 and API 619 standards represent two complementary philosophies in the world of industrial compressors. While the former defines the highest level of engineering for clean gases and critical services, the latter provides robustness and flexibility for more adverse operating conditions.

Understanding the technical differences between the two allows you to select the right equipment, optimize operation, and design maintenance strategies according to process needs.

In the oil and gas industry, where reliability is synonymous with profitability, API standards remain the technical benchmark that guarantees safety, efficiency, and durability in rotating equipment.

References

- https://www.api.org/products-and-services/standards/important-standards-announcements

- American Petroleum Institute (API-617/ API- 619)