Sustainable and efficient organic inhibitors are compounds that can be used to mitigate corrosion in various industrial applications. These are environmentally friendly and offer acceptable inhibition efficacy.

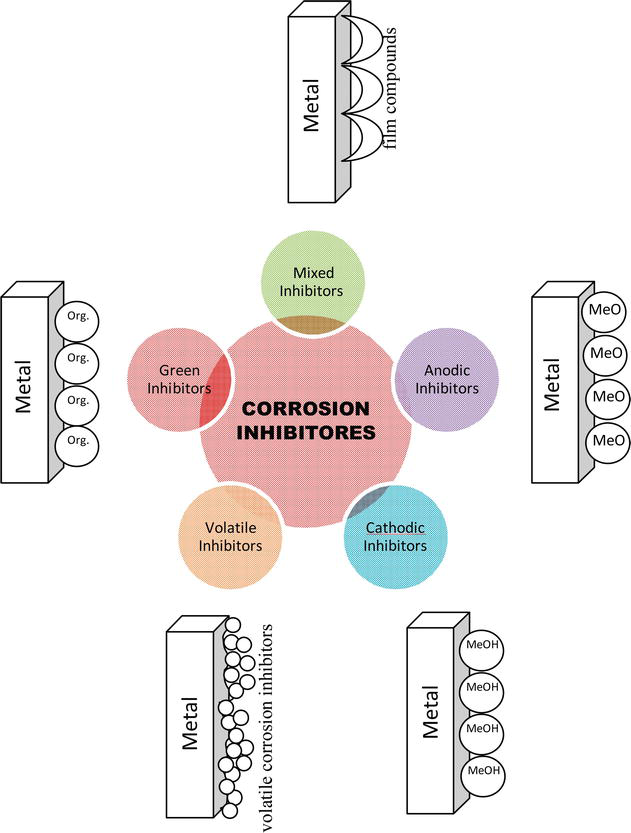

They are chemical substances that, added in small concentrations to the corrosive medium, act at the metal-solution interface, significantly decreasing the corrosion rate of the metallic material exposed to it.

These compounds constitute chemical agents used with the purpose of preventing or retarding the corrosive process in metallic substrates. These operate by adsorbing at the metal interface and developing a protective film that attenuates the interaction of the metal with its corrosive environment.

Compared to other corrosion protection techniques, such as special coatings or alloys resistant to this corrosive process, these are usually cheaper and easier to apply. This increases its viability in various industrial applications.

They can also significantly extend the life of materials, reducing the need for frequent replacement and therefore wasted resources.

In addition, they can be designed to be less toxic and more biodegradable, which decreases their impact on the environment compared to more harmful conventional ones.

Sustainable Organic Inhibitors and Corrosion

Metallic materials are widely used for various applications, for example as building materials, especially in the oil and gas industries. However, most metals in their pure form are thermodynamically unstable and therefore easily undergo corrosive degradation from the reaction of constituents in the surrounding environment.

Safety issues and economic damages

According to a recent estimate by NACE (National Association of Corrosion Engineers), the global cost of corrosion is around $2.5 trillion, which constitutes about 3.5% of world GDP.

This cost can be direct or indirect. The direct cost includes the repair, storage and replacement of corroded metal equipment, modifying alloys into metals and vice versa.

Indirect costs include liquid (petroleum) and gas leaks from transportation pipelines that negatively affect machinery performance and transportation efficiency.

This phenomenon also arises due to the presence of solid deposits, sand, scale and products of corrosive agents (Figure 1). It builds an extra layer that the inhibitor has to overcome. It also adsorbs the active components and promotes the growth of bacteria, which leads to microbial corrosion.

Therefore, the most suitable inhibitor is required for protection. Two types are required depending on the type of aggressive medium (1) soluble in water and (2) soluble in hydrocarbons.

Water solubles are used in oil production and transportation and in the descaling process. Corrosion caused by CO2 (sweet corrosion) and H2S (sour corrosion) is the most frequent form of attack in oil and gas production.

Currently, organic compounds are established as one of the most effective and profitable inhibition methods due to their association with E4 (efficiency, economy, ecology and respect for the environment).

Trends in environmentally friendly organic inhibitors.

Current trends in the development of environmentally friendly inhibitors are focused on the search for innovative and technological solutions that promote sustainability and reduce environmental impact. Some of these trends include:

1. Biological inhibitors: Microorganisms and biological products are being investigated as alternatives to traditional chemical inhibitors. These biological agents take advantage of natural processes to control climate in a sustainable way.

2. Nanomaterials as inhibitors: As metallic nanoparticles and nanometric compounds, they are being studied as effective and environmentally friendly inhibitors.

3. Polymeric inhibitors: Conductive polymers and other functional polymers are being explored as corrosion inhibitors.

4. Plant-derived inhibitors: Plant-derived extracts and compounds are being developed for their ability to inhibit this process. These natural products are a sustainable alternative to synthetic chemicals.

5. Inhibitors based on ecological salts: Less toxic and environmentally friendly inorganic salts are studied as corrosion inhibitors. These compounds are less harmful to aquatic ecosystems and other forms of life.

6. Focus on durability and efficiency: It seeks to develop inhibitors with a long useful life and high efficiency at low concentrations, which reduces the total amount required and minimizes the environmental impact.

7. Controlled release technologies: Controlled release systems for inhibitors are being investigated, increasing their effectiveness by releasing them gradually and sustainably over time.

8. Life Cycle Assessment and Sustainability: In addition to inhibition effectiveness, attention is paid to the life cycle assessment of inhibitors, considering their production, use and disposal to determine their overall environmental impact.

Current trends in the field of environmentally friendly inhibitors focus on the use of organic compounds derived from renewable sources, specifically biopolymers and bioresins.

These compounds demonstrate enhanced sustainability attributes due to their biodegradability, which significantly mitigates their overall ecological footprint.

Another prominent direction in research concerns the development of “green inhibitors.” This implies the search for compounds devoid of heavy metals or dangerous chemical substances, thus strengthening the safety of both the workers who handle these products and the ecological environment in which these compounds are applied.

In addition, an innovative line that is being explored involves the incorporation of controlled release mechanisms into the systems. This strategic integration aims to optimize the efficiency of these compounds while minimizing consumption frequencies.

This, in turn, improves operational efficiency and decreases the need for recurring applications.

Here are some key points:

1. Purpose: They are designed to create a protective layer on the surface of the material, acting as a barrier against corrosive agents or factors that could cause degradation.

2. Mechanism: They work by adsorbing on the surface of the material, forming a thin film that avoids direct contact with the aggressive environment.

3. Types of organic inhibitors:

– Organic corrosion: These include organic compounds such as amino acids, alcohols and amines. They are commonly used in industries such as oil and gas, petrochemical, and marine applications.

– From nitrites: These contain nitrite ions as an active ingredient and are often used in cooling water systems and boilers.

– Ecological: With the growing concern for the environmental impact of these chemical compounds, there is a progressive interest in developing them of the ecological type.

“Sustainable organic inhibitors with the ecosystem”

During the last two decades there has been a considerable increase in research and development of new compounds with low toxicity. Efforts around the world have been directed to the search for more suitable compounds that comply with the restrictions imposed on dangerous substances.

Given the recent attention towards the development of new compounds, it is important to note that, in addition to focusing on their anticorrosive efficacy, both toxicity and the increasingly stringent environmental regulations surrounding their application and disposal must be considered.

Eco-friendly corrosion inhibitors are biodegradable, low toxicity, low volatility, low cost, good for water solubility, good adsorbent, and do not contain heavy metals or other toxic compounds.

They are compatible with nature and offer acceptable inhibition efficiency. They can be used in various industrial applications such as oil and gas, petrochemical, and marine applications.

In response to this need, various investigations have addressed the implementation of environmentally benign approaches by incorporating the natural type.

Various eco-friendly types are available on the market today that seek to provide more environmentally friendly protection to prevent or reduce the degradation of metals and materials in corrosive environments.

Some examples of common corrosion inhibitors include

1. Polymer-based: They use polymers that form a protective film on the surface of the metal, creating a physical barrier that isolates the metal from the corrosive environment.

2. Amine-based: Organic compounds, can be adsorbed on the metal surface and form a protective layer. Some amines used are biodegradable and less harmful to the environment.

3. Based on plant compounds: Some plant extracts contain natural compounds that have shown inhibitory properties. These extracts may be less toxic and more sustainable than conventional chemical inhibitors.

4. Nanoparticle-based: Used in coating formulations or dispersed in fluids to provide protection.

5. Based on enzymes: They have the ability to modify the metal surface and form protective films. These may present advantages in terms of sustainability and reduced toxicity compared to conventional chemical alternatives.

Conclusion

These technologies are biodegradable, free of heavy metals, and environmentally friendly, making them a sustainable and cost-effective solution for corrosion prevention. By embracing these green technologies, we can promote sustainable results. In general, corrosion inhibitors find a wide field of application in practically all kinds of industries.

References

- Journal of Adhesion Science and Technology. https://www.tandfonline.com/

- https://inspenet.com/articulo/inhibidores-ecologicos-control-la-corrosion/

- W.von Baeckmann, W. Prinz, W. Schwenk/ Handbook of Cathodic Corrosion Protection /Gulf Publishing Company.