Table of Contents

- Introduction

- Considerations and precautions to be taken into account

- Know the weight of the load

- Load Center of Gravity (CG)

- lifting hook

- Shackles

- staples

- Calculation of forces exerted by crane support points

- Calculation of forces acting on the ground during hoisting

- COVENIN Standards to be consulted

- Conclusions

- Bibliographic references

Introduction

The present work describes the most notable characteristics, the technical aspects and the safety criteria of the load lifting tools with the greatest presence in the workplace .

The load lifting equipment is very required in the industries of line production, operations, construction and services, to perform activities that require the assistance of this equipment for its versatility to lift loads and move them to lower and upper sites, and many times to place them on load platforms to be transported to other places; However, if some provisions for their reliable use are not considered, some of the elements that integrate them may present failures; as well as, the way to handle each particular hoisting situation such as crane stabilization, load lashing or unlashing, hoisting plan, floor load, centers of gravity and moments of inertia.

For this reason, incidents due to equipment collapses and/or falling loads are the failures that occur and cause severe or catastrophic consequences that involve the loss of human lives of own personnel or third parties; as well as, damage to the facilities, means of production, and paralysis of the same.

In any lifting maneuver, as logical and obvious as it may seem, there is a risk of falls. The consequences and associated costs can be very high if the appropriate measures are not taken; It is necessary to consider not only the fall of materials and/or equipment that may later present damage or become unusable, but also in the most serious cases, loss of human life. Ensuring the protection of workers against the risks caused by work teams is one of the broadest and most complex fields of the occupational safety specialty.

Among the most important factors to consider for the success of project work where lifting machinery is involved; In order for these procedures to be carried out correctly, the following are necessary:

Considerations and precautions to be taken into account

- Certification and operability of lifting equipment: All load lifting equipment must be certified by a recognized entity, which endorses the inspection of the equipment: the required load test has been performed, and it meets the required operability and safety conditions.

- Certification of the lifting equipment operator: The person handling the lifting equipment must have a certificate from a recognized entity that certifies his or her training in the use and handling of the equipment and heavy loads.

- Delimitation and Anchor Radius for hoisting: When hoisting, the crane must be anchored in a flat point, according to the center of gravity and taking into account the weight of the load, the radius to be delimited will be the length of the anchor cable. multiplied by two, when delimiting, cordoning tape and safety cones should be used to prevent personnel or vehicles from moving in the vicinity or under the load.

Know the weight of the load

The main thing in a lifting job should be the load; so it is of the utmost importance to monitor its security. which is directly related to the weight exerted on the lifting equipment. Knowing the weight is the fundamental factor to determine the characteristics of the lifting equipment and even the ideal machinery to carry out the work. The more weight the load has, the more resistance should be both the machine in general, and the equipment that will be used.

To determine the exact weight of the load, certain characteristics must be evaluated; such as, for example, the material, its shape or design, among others such as:

Rated Weight or Capacity: Maximum weight that the lifting equipment can lift according to the design conditions, capacity and operating condition indicated by the manufacturer. Established weight: It is the one indicated by the manufacturer or by the packaging company.

Gross weight: Net weight + tare.

Calculation of the weight of the load: It can be done using the following formula.

P = V x Pe.

Where: P= Weight; V= Volume. Pe = Specific weight of the material.

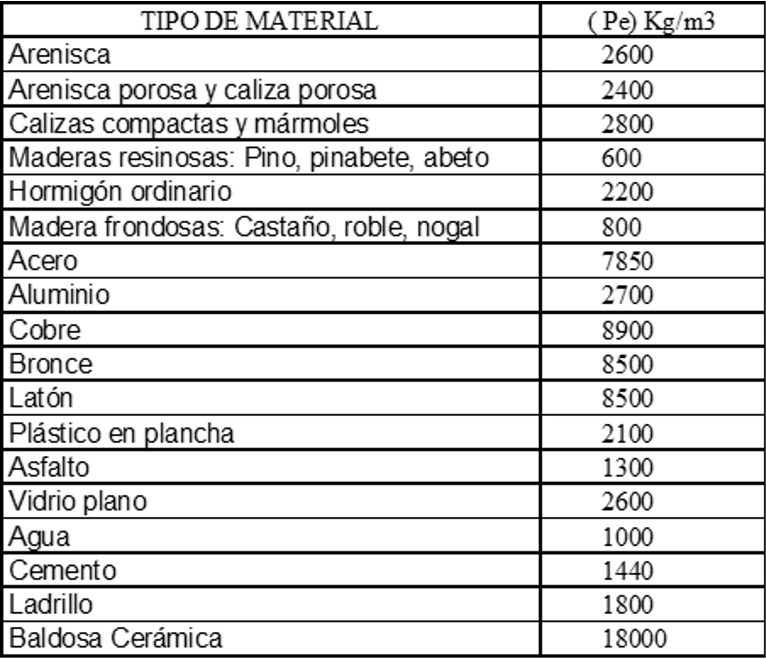

Table of specific weight of some materials.

Table 1 shows the specific weight of some materials necessary to determine the weight of the load to be lifted by the lifting equipment.

Load Center of Gravity (CG)

It is defined as the point where all the mass of any object is concentrated. Its location is very important before carrying out lifting work; in order to be able to correctly place the slings, chains or any other tool that allows securing the load. In most cases, where an object of symmetrical proportions is presented, the center of gravity is the midpoint; however, when it has an asymmetrical shape, a decomposition of the object is carried out in order to locate different centers of gravity and thus finally determine a single CG.

Location of the Center of Gravity of the load (CG) of symmetrical shapes:

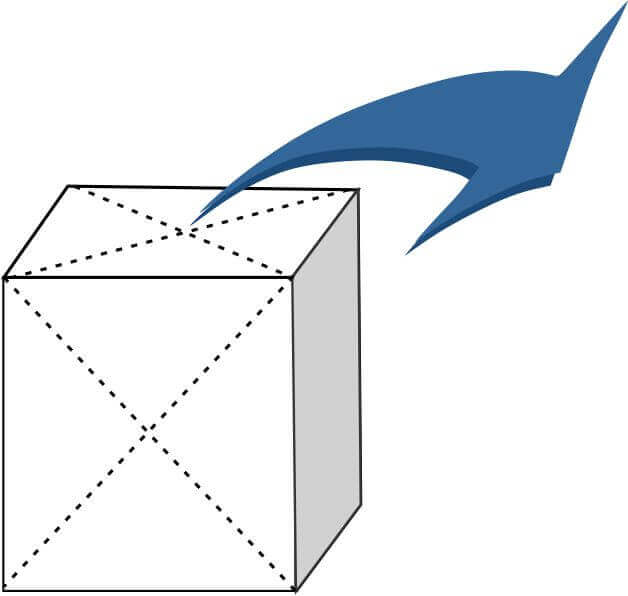

In figure 1, the Center of Gravity (CG) is shown: It is a fixed point in a body, through which the line of action of the weight passes.

In bodies whose figure is symmetrical, the center of gravity is at the intersection of its diagonals.

Figure 1. Center of Gravity (CG) for a symmetrical body.

Graphic method to determine the center of gravity of asymmetrical objects.

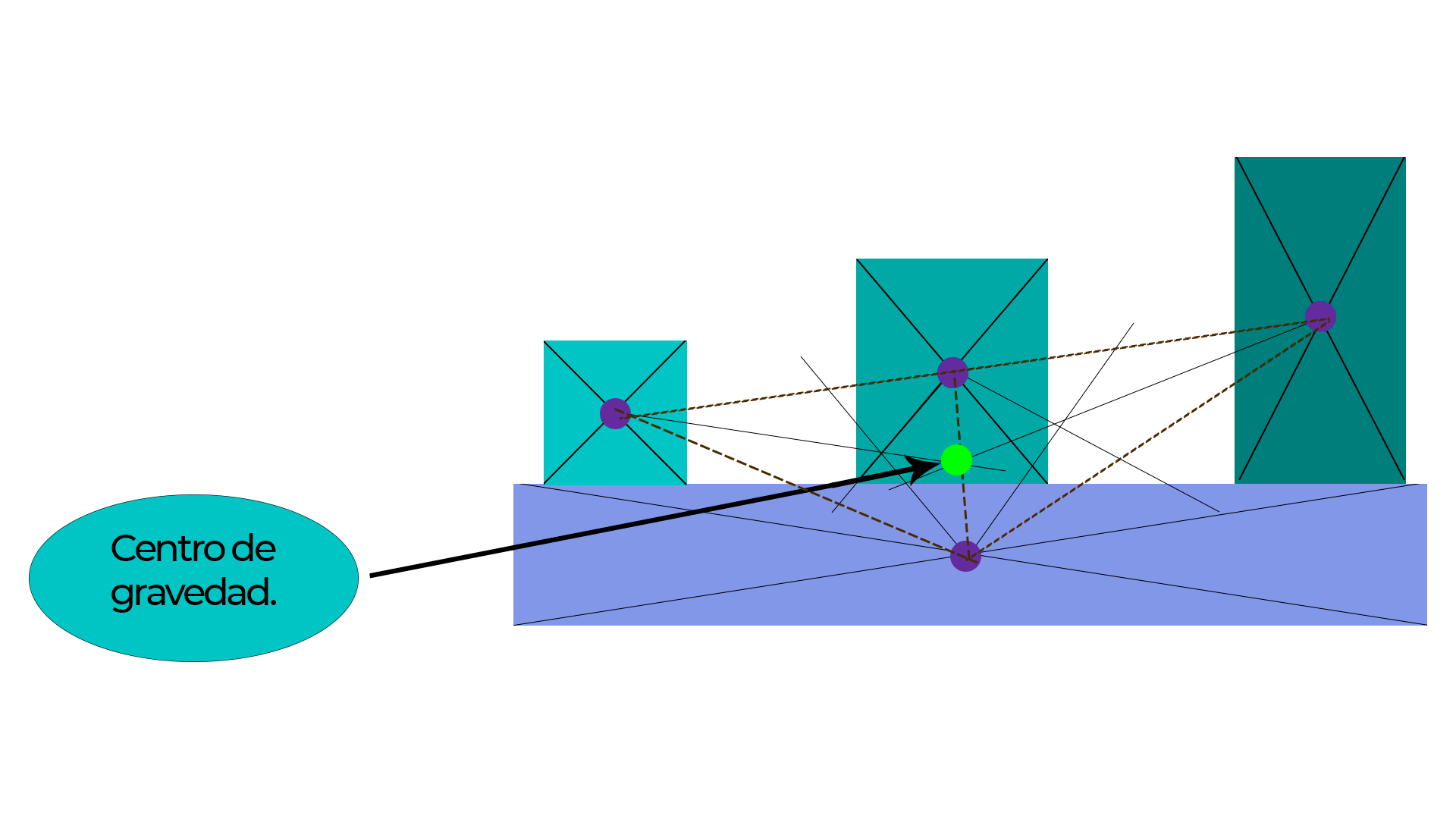

Figure 2 shows the steps to follow to calculate the CG in asymmetric objects.

- Decompose the shape of the load into rectangles.

- Find the center of gravity of each rectangle (in the plane).

- Join the centers of gravity with a line.

- Form triangles.

- Take the bisectors of the triangles.

- The Center of Gravity will be approximately in the center of the

- resulting line, to join the intersection points of the bisectors.

Figure 2. Graphic calculation of the CG for asymmetrical objects.

A.- First method

A.1. Center of gravity of three bodies:

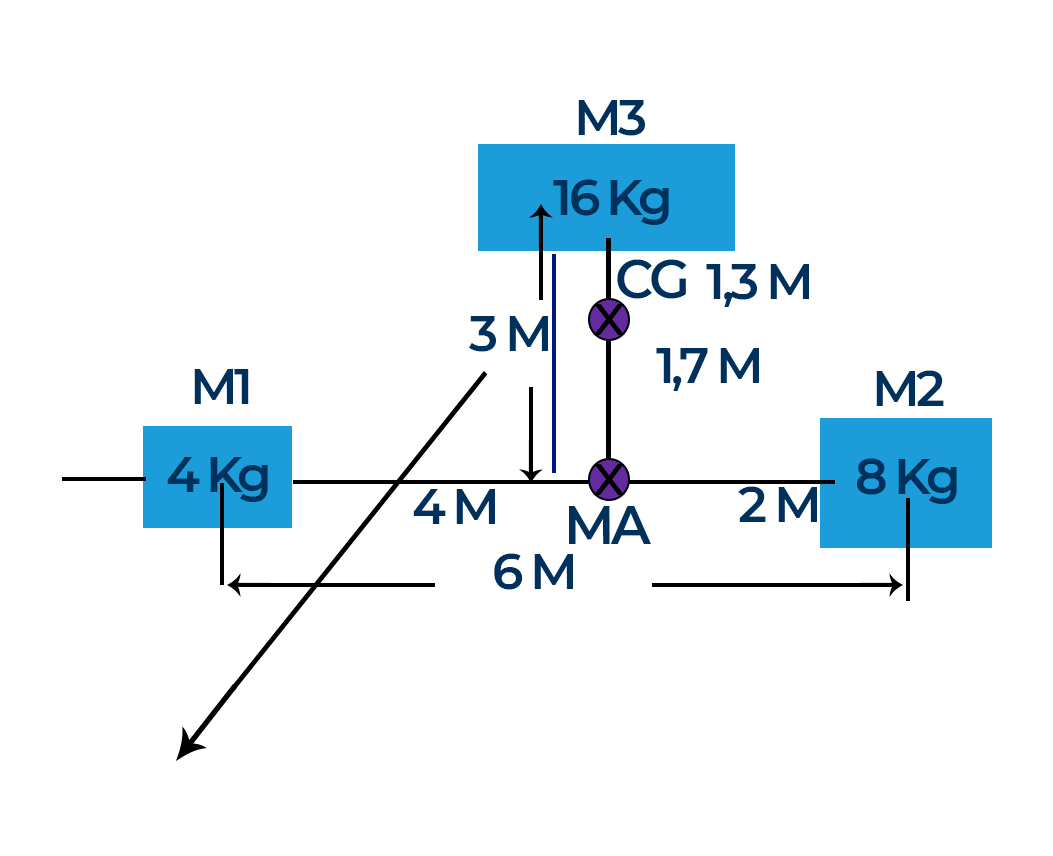

Example: Figure 3, graphically shows the data and steps to follow to carry out the mathematical calculation.

- The center of gravity of the M1 and M2 is calculated

- Add the masses M1 and M2 = 4 + 8 = 12 Kg

- Calculate the mass percentage of M1 and M2: 4/12 = 0.33 and 8/12 = 0.66

0.33 X 6 = 1.98 @ 2 AND 0.66 X 6 = 3.96 @ 4

- Calculate the center of gravity of MA and M3

- Add the masses MA YM3 = 12 + 16 = 28 Kg

- Calculate the mass percentage of MA and M3

12/28 = 0.43 AND 16/28 = 0.57

- 0.43 X 3 = 1.29 @ 1.3 AND 0.57 X 3 = 1.71 @ 1.7

Figure 3. CG calculation example.

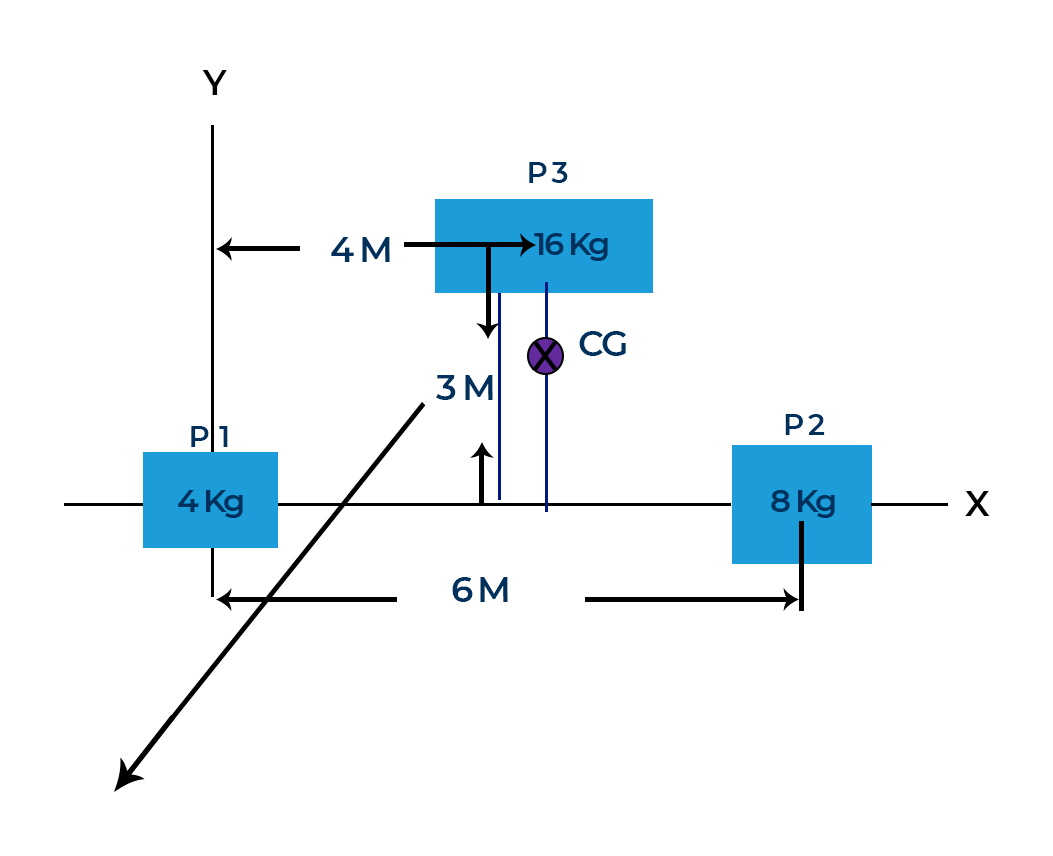

B.- Second method (X and Y coordinate plane).

Figure 4 shows the steps to follow for this method.

- P1 = 4 kg, X1 = 0, Y1 = 0

- P2 = 8 Kg, X2 = 6 M, Y2 = 0

- P3 = 16 Kg., X3 = 4 M, Y3 = 3 M

- The center of gravity is calculated at “x”

- X= åPX/ åP = (4 X 0) + (8 X 6) + (16 X 4)/(4 + 8 +16) = (48 + 64)/28 = 112/28 = 4

- Calculate the center of gravity in “Y”

- Y= åPY/ åP = (4 X 0) + (8 X 0) + (16 X 3)/(4 + 8 +16) = 48/28 = 1.71

Figure 4. CG (coordinate plane) calculation example.

lifting hook

It is a “J” shaped connector (Figure 5), where other connectors can be placed at its open end (seat) and where the rings, hooks and eyes of the slings are attached to the rigging of one of a team. load. They are devices for lifting, lowering and moving loads due to the effect of a motor that holds it with the help of a main cable and chains called slings that hold the loads to be moved.

Figure 5. Lifting hook.

The Cargo Hook: Before each use, it should be visually inspected according to the following steps:

Step 1: Inspect the hook for damage. Look carefully for cracks, sharp edges, burrs, deformities, or dents. Check bending or deformation.

Step 2: Inspect the hook for excessive corrosion or contamination affecting its operation. The lock and latch should operate easily without difficulty. The lock and latch must close completely. The latch must prevent the hook from opening when closed.

Step 3: Inspect the hook markings. Markings must remain and be completely legible.

Step 4: Inspect each component according to the manufacturer’s instructions.

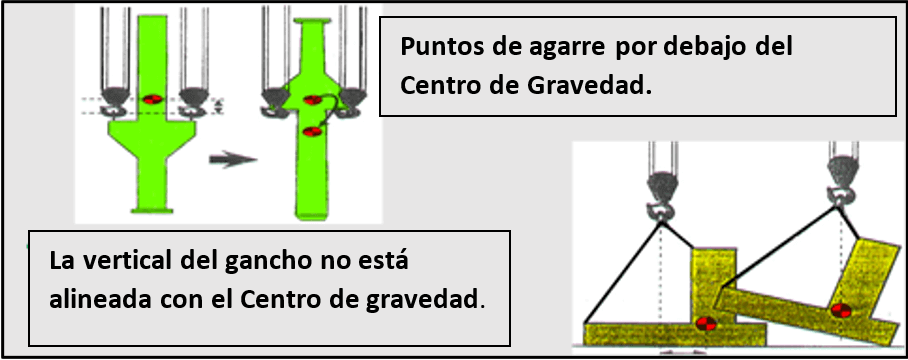

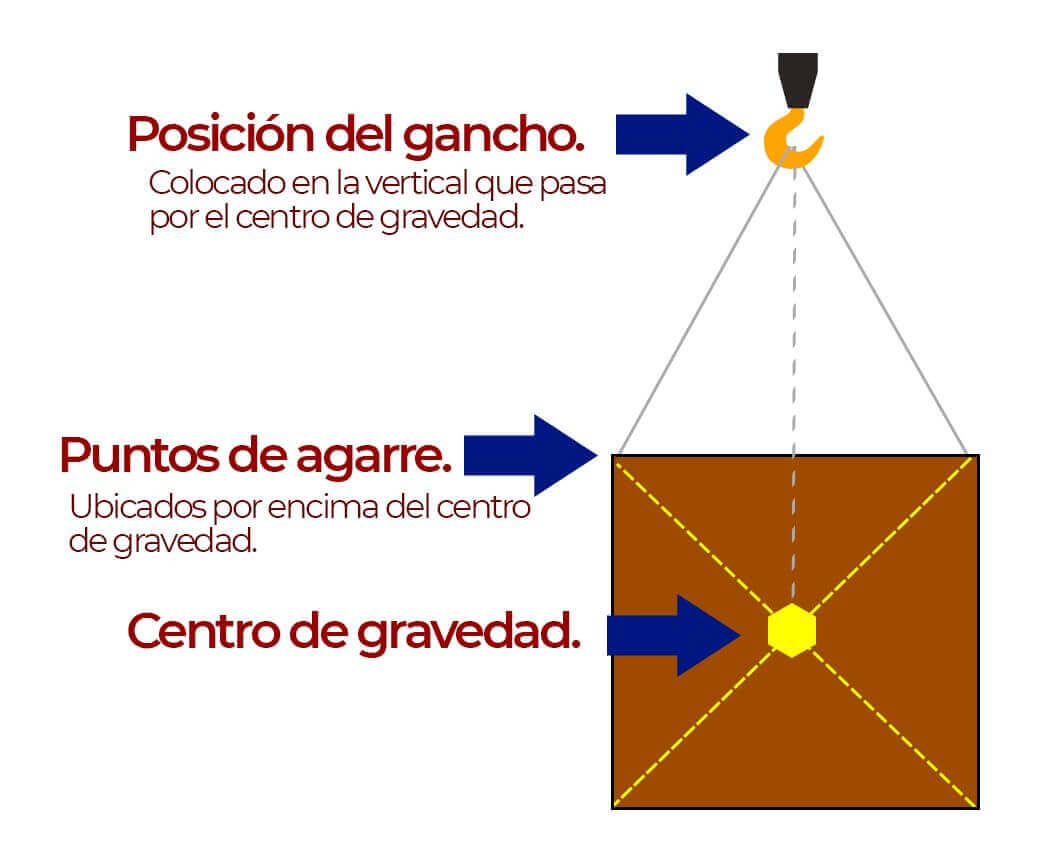

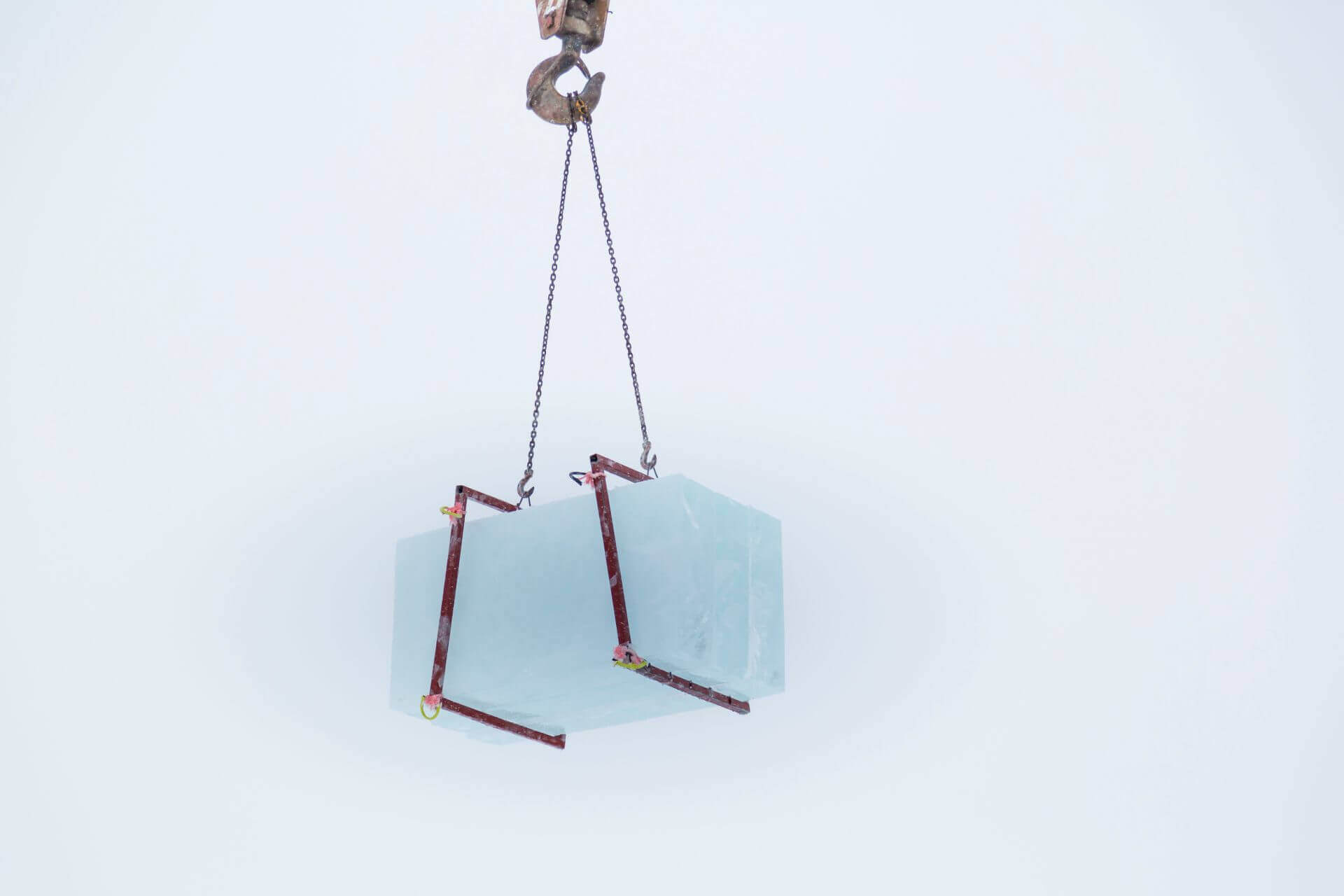

Balance on hoisted loads and load hook location

Every load when being hoisted will tend to seek stable equilibrium, that is, it will seek the situation in which its mooring point is in the same vertical as its center of gravity and above it (Figure 6).

Stable: When the center of gravity of the solid is below the mooring point, in this case the body tends towards verticality.

Unstable: When the center of gravity is above the mooring point. As soon as the center of gravity leaves the vertical, the body falls rotating around the mooring point.

Location of the load hook.

The maximum travel height of the crane hook is the vertical distance between the lowest level of the ground (including the pit, if any) and the load hook, when it is in the highest working position (Figure. 7 ).

Figure 7. Balancing loads and load hook location.

Slings:

It is a tape of specific dimensions provided with hooks to support large loads. They are flexible and very resistant, made of textile material, chemical fibers or even steel cables.

Figure 8. Types of slings.

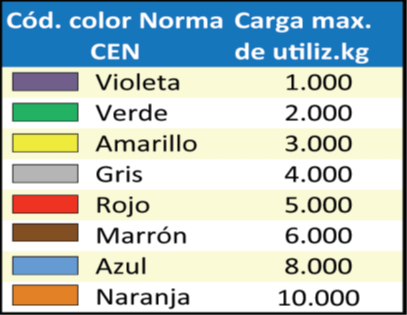

The maximum use load of textile slings is identified by a series of colors according to international codes (figure 8).

Figure 8. Specific color of a synthetic sling depending on the load.

Many factors influence the selection of the most appropriate cables for each crane application. The resistance of the cable, although of greater importance, is only one of these factors; it is therefore necessary and essential to use ropes of the size, type and construction required by the manufacturer for each crane application. Slings must be clearly marked with the maximum safe load and an identification number, i.e. all slings must be marked with the load capacity in kilograms.

Only slings for which a valid test certificate has been issued should be used, thus they can be used in a lift. Before using any lifting accessory such as slings, it is recommended that they be checked by a competent worker, slings in poor condition should be removed from service.

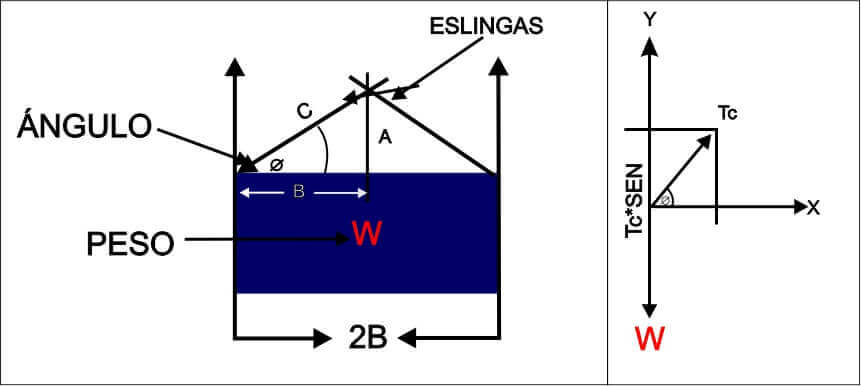

Calculation of the tension exerted on the slings.

In figure 9. graphical representation is shown to determine the tension exerted on the slings.

- ∑X= 0

- åY = Tc*SINθ – W = 0

- Voltage in C = W/SINθ

- The length of the slings must be C greater than and equal to 2B.

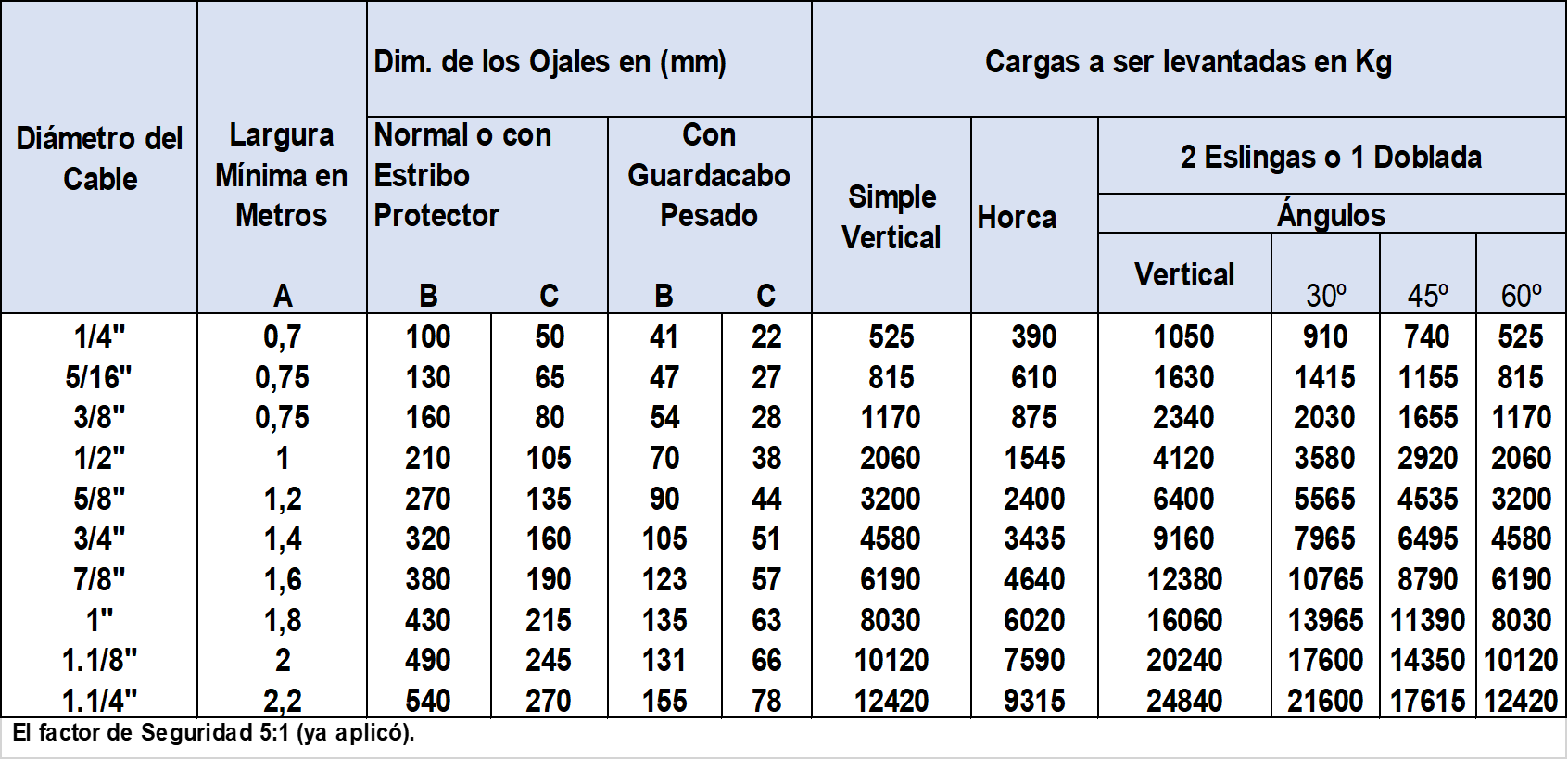

Table 2 presents information to consider for the selection of slings.

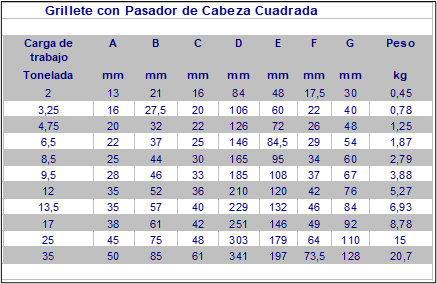

Shackles

They are made of steel and consist of a “U” shaped piece (Figure 10), with a forged steel pin passing through both ends, which serves to permanently connect a grommet to other fasteners.

Figure 10. Types of shackles.

They are two-piece connectors, a body and a flexible and resistant threaded pin, used to make the coupling between the load and a sling. Do not replace the original pin with any other type of element that substitutes its function, all shackles must be certified by the manufacturer and bear the maximum design load capacity in high relief.

Shackles are used in lifting systems, as well as in static systems, as connecting elements for cable, chain and other terminals. Punch head shackles are typically applied in both loading and non-permanent fastening operations. Locknut shackles are recommended for long-term or permanent installations or where the load could slip on the shackle pin causing it to rotate.

Steps for visual inspection of shackles.

Step 1: Examine the shackle for damage. carefully look for cracks, dents. Check bending or deformation.

Step 2: Inspect the shackle for pin or threading issues to establish rigging security.

Step 3: Check shackle markings. Markings must remain and be completely legible.

Step 4: Analyze each component according to the manufacturer’s instructions.

Step 5: Recognize wear in key points of the shackle which should never exceed 10%.

Step 6: Inspect for signs of excessive temperature, including weld spatter, impact or electrical spark damage or evidence of welding.

Step 7: Recognize replacement components not authorized or validated by the rig manufacturer.

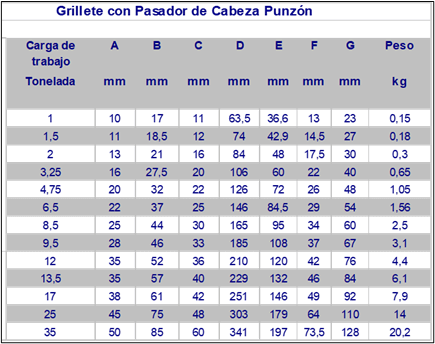

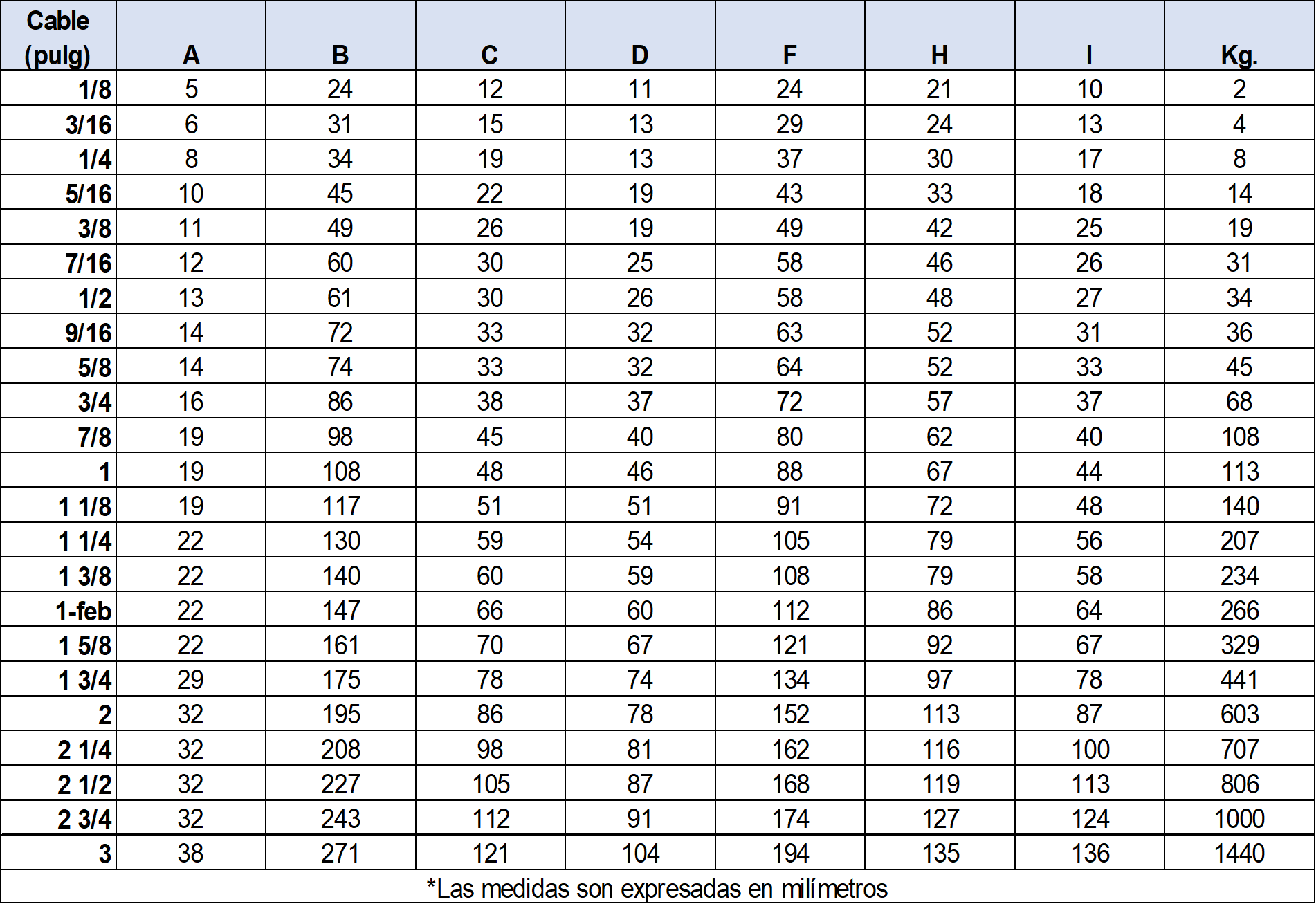

Tables for the selection of Shackles.

Tables 3a and 3b show the tables for the selection of shackles depending on the type:

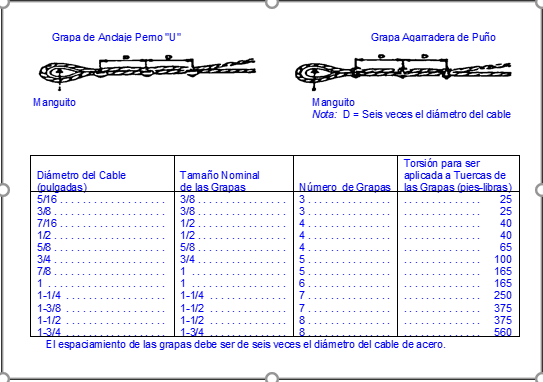

staples

Table 4 shows the type of clamp based on the inches of the cables,

These accessories, also known as clamps, are used in cable terminations, which are made by a set of metal pieces formed by a “U” bolt with its ends threaded and a perforated plate or base. (Figure 11).

Figure 11. Staples used for Lifting.

Staples for steel cables.

Table 5 shows the type of staple depending on the diameter of the steel cable.

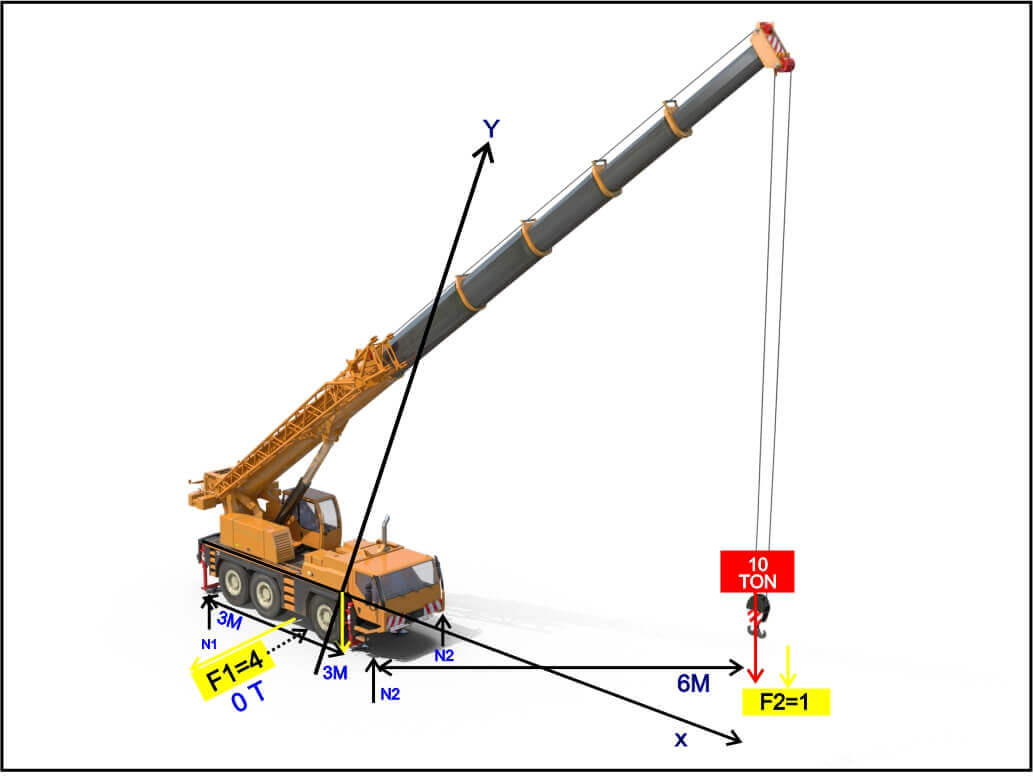

Calculation of forces exerted by crane support points

Next, a procedure is presented to carry out the necessary calculations to determine the forces that act on the ground during a loading process according to the information shown in figure 12.

Figure. 12. Forces exerted by support points of a lifting equipment.

Calculation of forces acting on the ground during hoisting

Sum of forces:

- ΣFx =0

- ΣFy = -F1 – F2 + N1 + N2

- ΣFy = -40 – 10 + N1 + N2 = -50 + N1 + N2

- N1 + N2 = 50 Tons. (1)

Sum of Moments:

- ΣM2 =0

- ΣM2 = -N1*(6M) + N2*(0M) + F1*(3M) – F2*(6M)

- ΣM2 = -N1*(6M) + N2*(0M) + 40*(3M) – 10*(6M)

- N1*(6) = 60 Tons.

- N1 = 60/6 = 10 Tons.

- N1 = 10 Tons .

Since equation (1) IS N1 + N2 = 50 TON., then the values of N1 are substituted in equation (1) and N2 is solved.

- N2 + 10 = 50 Tons.

- N2 = 50 – 10 = 40 Ton:

- N2 = 40 Tons.

Force on the front supports:

F3=40/2=20 Tons.

Data: Soil bearing load (P1=1.9 Kg/CM 2 )

Data: Area of each leg = 0.85 M 2 = AP

Pressure exerted by each leg on the ground.

P=F3/AP=20/0.85= 23529 Kg / M2

23529Kg/M2 X 1M2 / 10000CM2 = 2.4Kg / CM2

The force exerted by the crane supports is greater than the bearing load of the ground, for this reason the hoist cannot be carried out.

Calculation of the area of the crane supports to lift the weight on a floor whose bearing load is P1 = 1.9 Kg/CM 2.

P1= F3/AP = 1.9 Kg/CM 2 = 20000 Kg/AP

AP = 20000 Kg /1.9 Kg / CM2 = 10526.32 CM2 = 1.052632 M2

The area to be considered at each crane support must be 1.052632 M2

P= F3 / AP = 20 / 1.052632 = 18999 Kg / M2

18999 Kg/ M2 X 1 M2 / 10000CM2 = 1.8999 Kg / CM2

COVENIN Standards to be consulted

3088 – 2000 3224 – 1990 3177 – 1995

3089 – 2000 3210 – 1996 3511 – 1999

3131 – 2000 3268 – 1996 3176 – 1995

3175 – 1995 3211 – 1996 3512 – 1999

3132 – 1994 3188 – 2000 1611 – 1996

3174 – 2000 3212 – 1996 3267 – 1996

3510 – 1999 3223 – 1996 3333 – 1997

3331 – 1997 3332 – 1997 3329 – 1997

Conclusions

Not only the certificates of the accessory equipment and personnel are important: the conditions of the soil must also be inspected and checked, be it natural terrain, compacted, already covered with asphalt, with concrete slabs, in any of the areas of the industries. as well as cross-country.

Bibliographic references

- COVENIN standards.

- Rafael R Ruda. “Operation manual for cargo lifting.

- CRANES. Emilio Larrodé and Antonio Miravete. Edited by the publication service of the Higher Polytechnic Center of the University of Zaragoza.

About the Author

Ramón J Reyes A. Industrial Engineer, with a Postgraduate Degree in Occupational Health, dedicated and trained in the area of Industrial Safety, Environment and Occupational Health, with 33 years of experience in Safety, operations of thermoelectric plants, construction of industrial, oil, and petrochemical plants. and gas as well as in the installation of platforms for wellheads and installation of anchors for the grip of FSO used as a storage tank and dispatch of crude oil