If you ever have the fortune to visit Rome, you will see how the dome of the Pantheon rises imposingly, nearly two millennia after its construction. And if you reach the ports of the Mediterranean, you will encounter pillars of concrete submerged in saltwater that defy not only the passage of time but also the logic of modern engineering. These structures stand as silent witnesses to the superiority of an ancient material: opus caementicium, or Roman concrete. For centuries, we attributed its longevity to mysticism or luck, but modern science has unraveled its secrets, revealing that not only are we capable of emulating it, we can surpass it.

Why has Roman concrete endured for more than 2,000 years, while modern concrete lasts barely a century? The arrival of Portland cement 200 years ago, and now that of self-healing concrete, does not simply represent a technological advance; it is the culmination of a dialogue between past and future, where ancient wisdom fuses with nanotechnology to create materials that could triple the lifespan of our infrastructure, far surpassing the already astonishing durability of Roman concrete.

How does Portland Cement differ from Roman Concrete?

The radical divergence between modern Portland cement and Roman concrete is not one of ingredients, but of chemical philosophy. Contrary to what one might think, the goal remains the same: to endure through time with the least possible degradation.

Portland Cement

Invented in the 19th century, it was the product of industrialization—and also of chance. In 1824, Joseph Aspdin, searching for a stronger mixture for his works, calcined limestone and clay in a kitchen oven. The result was a product called clinker, later ground with gypsum. Its strength derives primarily from the formation of calcium-silicate-hydrate (C-S-H), an amorphous, dense gel. But it has a weakness: it is rigid and brittle.

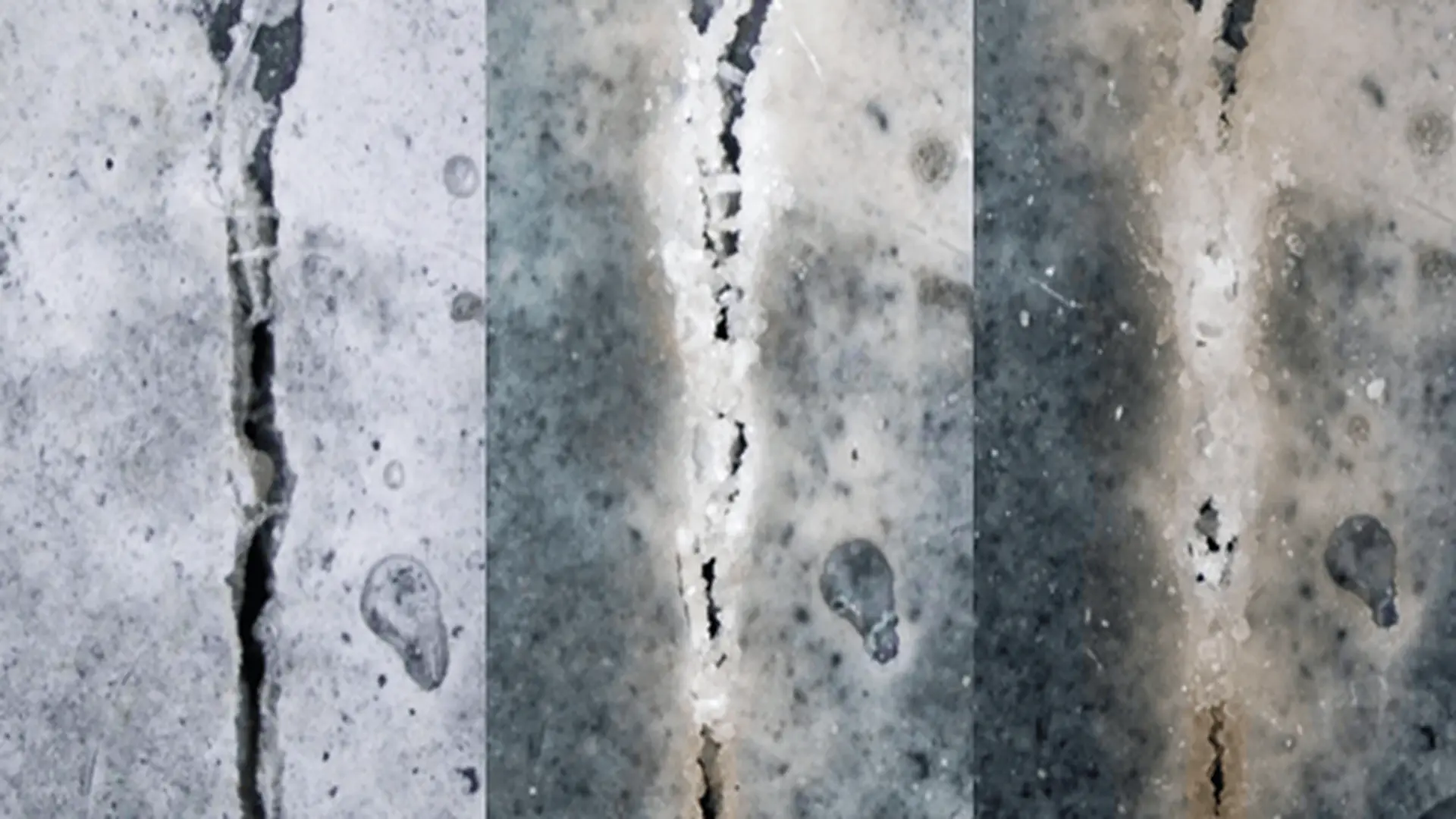

Microcracks are inevitable due to stress, shrinkage, and load cycles. Once water and aggressive agents such as chlorides and sulfates penetrate these cracks, they corrode the reinforcement steel and degrade the matrix, accelerating the structure’s decline. Its design lifespan typically ranges from 50 to 100 years, requiring costly and constant maintenance (Scrivener et al., 2018).

Roman Concrete

It must first be clarified that the Romans did not have access to high-temperature kilns. Their genius was empirical and practical. They mixed quicklime (CaO) with pozzolana, a volcanic ash rich in silica and aluminum. The marvel occurred upon hydration. Instead of merely forming C-S-H, the reaction between lime, pozzolana, and seawater (in maritime structures) produced a blend of extremely stable crystalline minerals, such as strätlingite and, fundamentally, aluminous crystalline tobermorite (Jackson et al., 2014).

These crystals act as microscopic internal reinforcement. Even more fascinating, recent research has revealed that Roman concrete is not static. The constant washing of seawater through its pores does not damage it—it heals it! Seawater slowly dissolves residual lime, providing calcium ions and alkalinity for the pozzolana to continue reacting, forming additional sealing minerals, according to research conducted at the Massachusetts Institute of Technology (MIT, 2023).

Although saline environments normally corrode and damage structures, how does Roman concrete “self-heal” when interacting with seawater? Because it passively regenerates itself over centuries. It did not require steel reinforcement, since its mass and structural design (such as the use of arches and vaults in bridges and other structures) distributed loads efficiently, while its chemical matrix was inherently resistant to the very agents that plague modern engineers.

The past still teaches

Current examples demonstrate its resilience. The superiority of the Roman principle is not merely theoretical; it manifests in structures that today serve as natural laboratories.

Caesarea Maritima Harbor (Israel)

Built by Herod the Great, its submerged pilings have withstood two millennia of marine agitation. While adjacent modern concrete piers show severe sulfate degradation and erosion in just a few decades, the Roman ruins remain dense and coherent. Core analyses reveal layers of secondary minerals formed through reactions with seawater that sealed the structure instead of fracturing it (Oleson et al., 2014).

Retaining walls and foundations

Throughout Italy, Roman concrete cores extracted from walls and foundations display a capacity to “grow” with the substrate, adapting to minor ground movements by self-welding cracks—a process impossible for rigid Portland cement (Jackson et al., 2014).

These examples serve as time-validated proof of concept. Extreme durability requires dynamic, not static, chemistry.

The self-healing concrete that now surpasses the Romans

Replicating Roman concrete exactly as it was is unfeasible; our construction scale and need for rapid initial strength are different. However, we have understood its fundamental principle: self-healing. Modern engineering does not seek to copy it but to reinterpret and improve it with nanotechnology. The current goal is not to build for 100 years, but for 500, 1,000, or more.

Current Strategies of Self-Healing That Surpass the Romans

- Microcapsules: This method incorporates tiny biodegradable polymer capsules containing sealing agents such as epoxy resin or sodium silicate into the mix. When a crack forms, the capsules rupture and release the “healing” agent, which polymerizes upon contact with air or water, sealing the fissure instantly (White et al., 2001). The response is immediate, far faster than the Roman process.

- Vascular networks: An innovative approach that creates networks of hollow microtubes within concrete, inspired by biological circulatory systems. A repair agent can be periodically pumped through this network, flowing to cracks and healing them actively and repeatedly (Toohey et al., 2007). This surpasses the Roman limitation of relying on a finite reagent like lime, since the “immune system” can be replenished.

- Limestone-producing bacteria: Biotechnology applied to concrete. Spores of bacteria (such as Bacillus pseudofirmus) and their nutrient (calcium lactate) are incorporated into the mix. These spores remain dormant for decades. When water enters a crack, the spores hydrate, bacteria “awaken,” consume the nutrient, and as a byproduct, precipitate calcite (CaCO₃), sealing the crack in perfect compatibility with the matrix (Jonkers, 2011). It is a version 2.0 of the Roman process: instead of a slow chemical reaction, we employ programmed microorganisms to achieve the same task more efficiently and directly.

Conclusion

Roman concrete proved that true durability lies in the capacity for active regeneration. Today, self-repairing concrete takes this principle to new heights through programmed and biological systems that could extend the useful life of structures to 6,000 years, far surpassing the legendary strength of Roman works.

The final lesson is profound. Sustainable construction is not necessarily about exotic new materials but about observing the intelligence of the ancients and of nature itself. By combining the wisdom of opus caementicium with the power of nano- and biotechnology, we are closing a historical circle. We are not merely building infrastructure; we are creating petrified legacies—living structures that breathe and heal themselves, destined to tell our story to civilizations yet unborn.

References

- Jackson, M. D., Mulcahy, S. R., Chen, H., Li, Y., Li, Q., Cappelletti, P., & Wenk, H.-R. (2014). Phillipsite and Al-tobermorite mineral cements produced through low-temperature water-rock reactions in Roman marine concrete. American Mineralogist, 102(7), 1435–1450. https://doi.org/10.2138/am-2017-5993CCBY

- Jonkers, H. M. (2011). Bacteria-based self-healing concrete. Heron, 56(1/2), 1–12.

- Massachusetts Institute of Technology. (2023, January 6). Riddle solved: Why was Roman concrete so durable? MIT News. https://news.mit.edu/2023/roman-concrete-durability-lime-casts-0106

- Oleson, J. P., Brandon, C., Cramer, S. M., Cucitore, R., Gotti, E., & Hohlfelder, R. L. (2014). The ROMACONS project: A contribution to the historical and engineering analysis of hydraulic concrete in Roman maritime structures. International Journal of Nautical Archaeology, 43(2), 683–688. https://doi.org/10.1111/1095-9270.12069

- Scrivener, K. L., John, V. M., & Gartner, E. M. (2018). Eco-efficient cements: Potential economically viable solutions for a low-CO₂ cement-based materials industry. Cement and Concrete Research, 114, 2–26. https://doi.org/10.1016/j.cemconres.2018.03.015

- Toohey, K. S., Sottos, N. R., Lewis, J. A., Moore, J. S., & White, S. R. (2007). Self-healing materials with microvascular networks. Nature Materials, 6(8), 581–585. https://doi.org/10.1038/nmat1934

- White, S. R., Sottos, N. R., Geubelle, P. H., Moore, J. S., Kessler, M. R., Sriram, S. R., Brown, E. N., & Viswanathan, S. (2001). Autonomic healing of polymer composites. Nature, 409(6822), 794–797. https://doi.org/10.1038/35057232