Table of Contents

- What is a mooring system in offshore terminals?

- Modernization: Materials and technological solutions

- Structural integrity and operational performance assessment

- Technical requalification under international standards

- Challenges and trends in liquid hydrocarbon terminals

- The importance of secure mooring in maritime operations

- Consequences of mooring system failures

- Regulatory and compliance impact

- Assessment of mooring integrity

- Evaluation criteria for existing systems

- Emerging technologies in mooring systems

- Modernized design criteria

- Technical requalification processes

- Risk management and best practices

- Case studies and lessons learned

- Strategic recommendations

- Conclusions

- References

Mooring systems are a critical component in the operation of offshore terminals, single buoys, and floating production, storage, and offloading (FPSO) units. These systems, consisting of mooring lines, anchors, buoys, and specialized accessories, ensure the safety and operability of offshore facilities in adverse environmental conditions such as waves, wind, and currents. Currently, the industry faces the challenge of modernizing and reclassifying these systems, incorporating innovative technologies that increase the structural reliability of the facility.

The evolution toward smarter and more innovative mooring systems responds to the need to improve energy efficiency, extend the useful life of assets, and comply with increasingly stringent international regulations. This article analyzes the criteria for evaluating, updating, and requalifying mooring systems, taking as a reference the recommended practice API RP 2SK and its application in monobuoys or single point mooring (SPM).

What is a mooring system in offshore terminals?

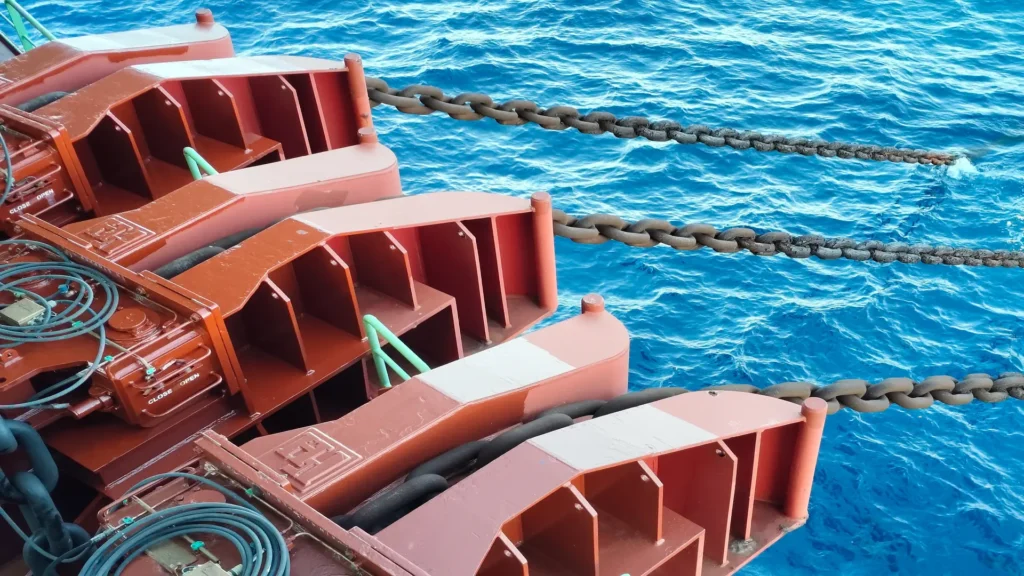

A mooring system is the set of components that ensures the position and stability of a floating unit, whether it is a tanker, a single buoy mooring, or an FPSO, against dynamic loads imposed by wind, waves, and sea currents. Traditionally, these systems have been designed with chains, synthetic ropes, and high-capacity anchors, whose dimensions depend on specific hydrodynamic analyses for each location. However, fatigue wear, corrosion, and accumulated stresses on metal elements represent a recurring challenge that affects the system’s service life.

In single-point mooring systems, the system allows the vessel to rotate freely around the buoy, reducing loads on the mooring lines. These systems are widely used in crude oil export terminals due to their operational flexibility and lower investment in fixed infrastructure compared to conventional ports.

Modernization: Materials and technological solutions

The modernization of mooring systems responds to the need to extend their useful life and adapt them to new regulatory and environmental requirements. In recent years, the use of composite materials and high-strength synthetic fibers has partially replaced conventional steel chains, offering greater flexibility and weight reduction.

In turn, the incorporation of state-of-the-art anti-corrosion coatings and cathodic protection systems has proven to be an effective tool against degradation due to marine exposure. Real-time monitoring, through IoT sensors and digital platforms, opens up the possibility of implementing digital twins that simulate the structural behavior of moorings, facilitating decision-making based on accurate data.

Automation and intelligent control in mooring systems

Automation has become a strategic focus in the evolution of mooring systems, enabling safer, faster operations with less direct human intervention. Automated positioning and release systems integrate hydraulic and electric actuators controlled from control rooms, reducing personnel exposure to risk areas during maneuvers.

In addition, the use of predictive control algorithms and dynamic positioning systems complements the operation of traditional moorings, adjusting line tensions in real time according to wind, wave, and current conditions. This technological integration not only increases efficiency but also improves the traceability of operational data, facilitating safety audits and optimizing scheduled maintenance tasks.

Structural integrity and operational performance assessment

Mooring systems must be assessed periodically, integrating both physical inspection of components and computational analysis of performance under different load scenarios. Factors such as material fatigue, corrosion accelerated by marine environments, and abrasion generated by continuous contact with the vessel are critical variables in the diagnosis.

The use of online monitoring technologies and hydrodynamic simulations allows for the anticipation of failures and the establishment of predictive maintenance plans, minimizing the probability of incidents and optimizing operational availability.

Technical requalification under international standards

Requalification is a key process to ensure that mooring systems continue to meet the safety criteria required by international organizations such as OCIMF, API, and DNV. This procedure includes controlled load testing, non-destructive analysis, and validation of design parameters against new operating conditions. In many cases, requalification allows the service life of an installed system to be extended, provided that it is demonstrated to comply with established tolerances and that appropriate corrective maintenance plans are implemented. This achieves a balance between operational safety, economic sustainability, and environmental responsibility.

Challenges and trends in liquid hydrocarbon terminals

The biggest challenge currently facing liquid hydrocarbon terminals is combining safety, efficiency, and sustainability in an environment of increasing energy transition. Mooring structures must respond not only to increasingly demanding operating conditions, but also to the need to reduce environmental impact through eco-efficient materials and less invasive maintenance processes. The future points toward hybrid systems that integrate artificial intelligence to predict failures, load optimization algorithms, and self-diagnostic mechanisms, consolidating a new standard of reliability in maritime terminal management.

The importance of secure mooring in maritime operations

A reliable mooring system is the basis for operational safety at maritime terminals and single buoys. The stability of a vessel during loading and unloading maneuvers depends on the strength and correct arrangement of the moorings, which must withstand dynamic forces generated by currents, waves, and winds. A failure in these elements can trigger high-impact incidents, from structural damage to oil spills with serious environmental consequences. Therefore, secure mooring is not only a technical measure, but a strategic requirement that ensures operational continuity and protects both the crew and coastal and offshore facilities.

Mooring systems are the first line of defense against environmental forces in offshore operations. Their failure can trigger a cascade of catastrophic consequences ranging from human loss to irreversible environmental damage.

Verified statistical data:

- According to DNV, the average failure rate for mooring lines is 1.23E-03 per year.

A study by Granherne found that on 33 FPSOs, 150 mooring lines had to be repaired or replaced over a ten-year period - In the last two decades, there have been more than 20 global incidents related to failures of permanent mooring systems on floating structures

Consequences of mooring system failures

- Critical risk factors: Fatigue degradation: Mooring systems are subject to constant cyclic loads from environmental forces (waves, wind, currents), which causes fatigue damage to accumulate that may not be detected until failure occurs.

- Accelerated corrosion: The aggressive marine environment accelerates corrosion processes, especially in:

- Air-water interface areas (splash zone)

- Bimetallic connections

- Areas with poor cathodic protection

- Points of contact with marine mooring

- Inspection and maintenance deficiencies: Mooring line selection is often based on incorrect criteria, resulting in reduced line response. Additionally, even if the criteria were appropriate, inadequate storage or maintenance procedures can lead to the same results.

Regulatory and compliance impact

Environmental responsibility:

Mooring failures can cause:

- Oil spills due to transfer system failure

- Damage to sensitive marine ecosystems

- Significant regulatory fines

- Suspension of operating permits

- Civil liability for environmental damage

Compliance with international standards:

- Loss of safety certifications

- Operational restrictions by maritime authorities

- Increase in insurance premiums

- Exclusion from demanding international markets

Assessment of mooring integrity

API RP 2SK: Design and analysis of position maintenance systems

API RP 2SK Design and Analysis of Positioning Systems for Offshore Floating Structures, in its fourth edition published in February 2024, is the fundamental standard for the design and evaluation of mooring systems. This recommended practice establishes deterministic analysis methods for system responses, differentiated criteria for mobile and permanent moorings, quasi-static and dynamic analysis procedures, safety factors and acceptance criteria, as well as time domain evaluation methodologies.

Periodic evaluation is essential to extend service life and prevent catastrophic failures. API RP 2SK establishes load analysis methodologies and safety criteria. Parameters evaluated include:

- Overloading of mooring lines: identified through hydrodynamic simulations.

- Corrosion and wear on chains and anchors: underwater inspection with ROV and thickness measurement.

- Fatigue of mooring cables and connectors: monitoring with tension sensors and load cycles.

- Behavior under extreme conditions: hurricanes, return waves, and design storms.

Mooring system integrity management

API RP 2MIM Mooring Integrity Management, published in 2019, provides a comprehensive management framework throughout the system’s life cycle. This standard covers comprehensive management from design to decommissioning, inspection and monitoring protocols, damage assessment and fitness-for-service analysis, risk reduction strategies and mitigation plans, as well as safe decommissioning processes.

Evaluation criteria for existing systems

A mooring system requires immediate intervention when it presents critical criteria such as a loss of nominal tension with a reduction of more than 15% in mooring lines, severe corrosion with a loss of cross-section greater than 10% in critical components, structural deformation with geometric deviations outside design tolerances, hardware failures manifested in fractures, cracks, or excessive wear in connectors, and excessive drift with displacements outside the permitted drift circle.

Early warning criteria include sustained increases in line tensions, abnormal vibrations or altered natural frequencies, degradation in monitoring systems, and changes in accumulated fatigue patterns.

Emerging technologies in mooring systems

Advanced monitoring systems incorporate IoT sensors with real-time transmission, predictive analysis using artificial intelligence, automated early warning systems, and integration with remote control centers. In terms of advanced materials, ultra-high-strength steel chains, high-modulus synthetic fiber cables, advanced anti-corrosion coatings, and intelligent cathodic protection systems are used.

Modernized design criteria

The new standards emphasize probabilistic analysis by incorporating uncertainties into the design, risk-based design with cost-benefit optimization of safety measures, environmental sustainability focused on minimizing ecological impact, and operational efficiency that seeks to reduce downtime and maintenance costs.

Technical requalification processes

Regulatory framework for requalification

The requalification of mooring systems must follow established protocols that include mandatory elements such as a comprehensive review of original documentation, updating of load analysis according to current conditions, evaluation of compliance with current regulations, and certification by a recognized independent body.

Step-by-step reclassification process

- Phase 1, called Preliminary Assessment, lasts 2 to 4 weeks and includes gathering historical documentation, general visual inspection, identifying undocumented modifications, and evaluating the overall condition of the system.

- Phase 2, Detailed Technical Analysis, lasts 6 to 8 weeks and includes updated numerical modeling, structural capacity analysis, accumulated fatigue assessment, and extreme condition simulation.

- Phase 3, Specialized Inspection, requires 4 to 6 weeks to perform detailed underwater inspection, load testing of critical components, evaluation of auxiliary systems, and complete photographic documentation.

- Phase 4, Compliance Assessment, takes 2 to 3 weeks and includes comparison with current standards, identification of compliance gaps, development of a corrective action plan, and estimation of remaining useful life.

- Phase 5, Certification and Documentation, completes the process in 1 to 2 weeks with the preparation of a comprehensive technical report, certification of compliance, development of an updated maintenance plan, and establishment of upcoming evaluation milestones.

Acceptance criteria for requalification

Structural criteria require a safety factor greater than or equal to 2.0 for operational loads, a safety factor greater than or equal to 1.67 for extreme loads, a remaining service life greater than or equal to 5 years for complete requalification, and the absence of critical non-repairable defects.

Functional criteria require the ability to maintain position within operational limits, proper functioning of safety systems, compatibility with current operational procedures, and emergency response capability.

Risk management and best practices

Risk mitigation strategies

Preventive measures include predictive maintenance programs, continuous monitoring systems, specialized personnel training, and updated operational procedures. Response measures include emergency response protocols, backup and redundancy systems, evacuation and rescue plans, and coordination with maritime authorities.

Case studies and lessons learned

- Case 1: SPM modernization in the Gulf of Mexico: The challenge involved a 25-year-old SPM system with severely degraded mooring chains. The solution implemented included replacing chains with higher-strength steel, installing real-time tension sensors, upgrading cathodic protection systems, and implementing a risk-based inspection protocol. The results achieved were a 15-year extension of service life, a 40% reduction in maintenance costs, and a 25% improvement in operational availability.

- Case 2: Recertification of the CALM system in the North Sea: The challenge was to comply with new environmental and safety regulations. The approach adopted included probabilistic analysis of extreme loads, advanced soil-structure interaction modeling, updated environmental impact assessment, and certification under ISO 19901-7 standards. The lessons learned highlight the importance of maintaining up-to-date documentation, the value of investing in monitoring technologies, the need for continuous staff training, and the benefits of a proactive versus reactive approach.

Strategic recommendations

- For terminal operators: Terminal operators should implement integrity management programs based on API RP 2MIM, invest in continuous monitoring and predictive analytics systems, develop internal capabilities for specialized technical evaluation, and establish relationships with certified service providers.

- For design engineers: Design engineers should adopt probabilistic analysis and risk-based design methodologies, incorporate sustainability and environmental impact considerations, use advanced modeling technologies for design optimization, and stay up to date on standards and best practices.

- For regulatory authorities: Regulatory authorities should promote the adoption of updated international standards, develop regulatory frameworks that encourage technological innovation, establish certification programs for specialized professionals, and encourage the exchange of information on lessons learned.

Conclusions

The assessment, modernization, and requalification of mooring systems is a cornerstone of comprehensive offshore terminal management. Proper implementation ensures safe operations, reduces environmental risks, and optimizes asset availability. Technological advances, together with compliance with international standards, will enable us to meet the challenges of an industry that is evolving towards more sustainable models, where innovation and integrity management will be decisive in ensuring operational continuity in a highly competitive market.

A good mooring system is the first line of defense for the stability of marine terminals and single-point mooring. Its evaluation under API RP 2SK, updating with advanced technologies, and periodic requalification ensure that the systems meet current demands for reliability, safety, and sustainability in offshore environments.

References

- API RP 2SK (4th Edition, 2024). «Design and Analysis of Stationkeeping Systems for Floating Offshore Structures»

- API RP 2MIM (2019). «Mooring Integrity Management»

- ISO 19901-7 (2013). «Petroleum and natural gas industries – Specific requirements for offshore structures – Part 7: Stationkeeping systems for floating offshore structures and mobile offshore units»

- DNV-OS-E301 (2010). «Position Mooring»

- OCIMF (2018). «Mooring Equipment Guidelines, 4th Edition»