Table of Contents

- Operating principle of cathodic protection

- Efficiency monitoring of cathodic protection systems

- How can check the effectiveness of cathodic protection?

- Technological innovations in PC monitoring

- Applications and benefits

- Why check the effectiveness of cathodic protection?

- Conclusion

- References

- FAQs on the efficiency of cathodic protection

Cathodic Protection (CP) is an advanced electrolytic corrosion control technique applied to metallic components exposed to electrically conductive environments. This technique is fundamental to prolong the service life of critical metallic structures such as pipelines, tanks, and offshore platforms. In this context, continuous monitoring of cathodic protection is crucial to avoid the deterioration of metallic structures in contact with electrically conductive environments. This practice is significant in the maintenance, structural integrity, and operational efficiency of industrial metallic structures.

The article focuses mainly on the aspects that can condition the effectiveness of cathodic protection systems over time, such as measurement techniques, control, and maintenance. It highlights how the correct use of appropriate techniques and modern remote monitoring systems for cathodic protection simplify control operations and ensures system efficiency over time.

Operating principle of cathodic protection

The basic principle of cathodic protection involves the application of a direct current between an electrode, called the anode, and the surface of the component to be protected, known as the cathode. This current reduces the electrical potential of the metal surface, significantly slowing down the corrosion process. There are two main methods of cathodic protection:

- Cathodic Protection by sacrificial anodes: Also known as galvanic protection, it depends on the typical potential of the anode, which is the most active metal and acts as sacrificial material (it corrodes) and the noblest will be the cathode (it is protected).

- Impressed Current Cathodic Protection (ICCP): Requires an external current source. This type of method also simulates an electrolytic cell, i.e. it resembles a battery. The material to be protected will function as the negative pole of the source, so it will be the cathode of the electrolytic cell.

Types of sacrificial anodes

The most commonly used sacrificial anodes are: Magnesium, Zinc, and Aluminum, each one has its application depending on the medium and certain conditions at the time of making a CP design, it is important to know the conditions of the medium for proper selection: Below are some of the characteristics of interest:

- Magnesium: Mainly for use in soils and fresh water. They are used in soils with low-condition coatings and even in soils of high resistivity with coatings that do not demand high current densities.

- Zinc: It is massively used, especially for cathodic protection in seawater. Main applications are: hulls of marine vessels, vertical condensers of wells, structures, and submerged lines, among others.

- Aluminum: Used specifically in seawater. Due to its electrochemical characteristics, it is the ideal material to be used as a sacrificial anode, its use as such is relatively recent. One of the disadvantages of aluminum is the formation of an aluminum oxide film (anodic passivation) which makes it very resistant to corrosion and therefore to “sacrifice”.

Efficiency monitoring of cathodic protection systems

The effectiveness of a cathodic protection system is confirmed if it is adequately controlling corrosion, although this corrosive process can be identified in some pipelines using smart pigs; however, directly determining the corrosion rate is not usually a simple process. Therefore, indirect methods must be used to assess the suitability of a cathodic protection system.

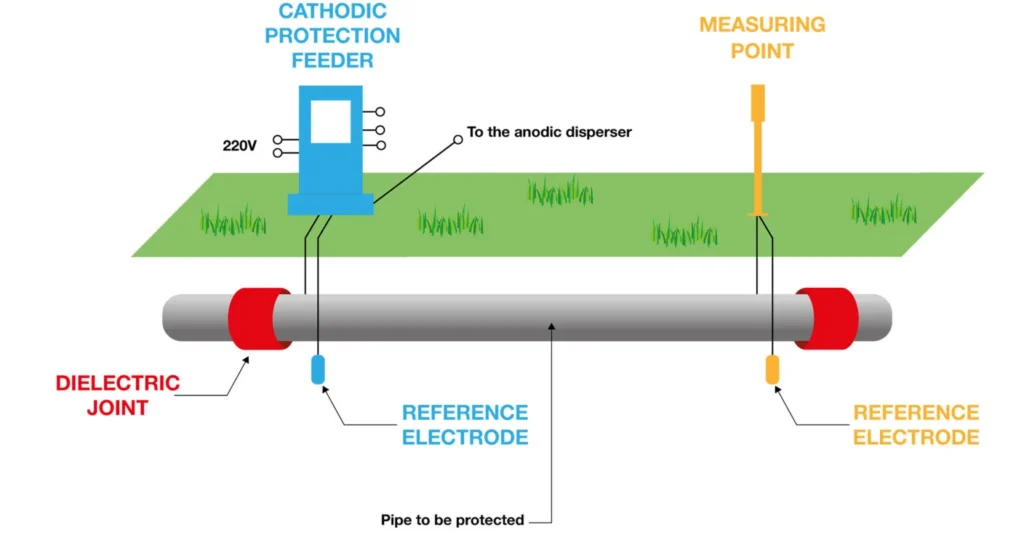

The activities related to the correct operation of the system for cathodic protection of lines and tanks correspond to: Monitoring and maintenance, each of which must be performed by trained personnel, through the use of appropriate tools and measuring instruments, in figure 1, an arrangement for monitoring the efficiency of a CP system is appreciated1.

The effectiveness of cathodic protection systems must be regularly monitored to ensure their proper functioning and to perform the necessary maintenance. During the design phase, measurement points are established in the distribution, transport, and storage networks. These points allow the acquisition of pipe-to-earth potentials such as a pipeline to be protected, and measurements necessary to program manual controls.

Advanced solutions for efficiency verification

Continuous verification of the efficiency of cathodic protection systems is strategic to ensure effective mitigation of electrochemical corrosion. Specialized companies such as Dairyland Electrical Industries provide advanced solutions that include remote monitoring systems based on telemetry, optimizing the measurement of cathodic protection in critical infrastructures.

These platforms allow the acquisition, collection of cathodic protection field data and real-time analysis of critical parameters such as bias potential (typically measured against a reference electrode such as Cu/CuSO₄ or Ag/AgCl), applied protection current and circuit resistance.

How can check the effectiveness of cathodic protection?

By making the electric potential of the metal to be protected more electronegative through application of direct current from an external source or bonding with a sacrificial material. The following are recommended steps to follow in monitoring the efficiency of a CP system.

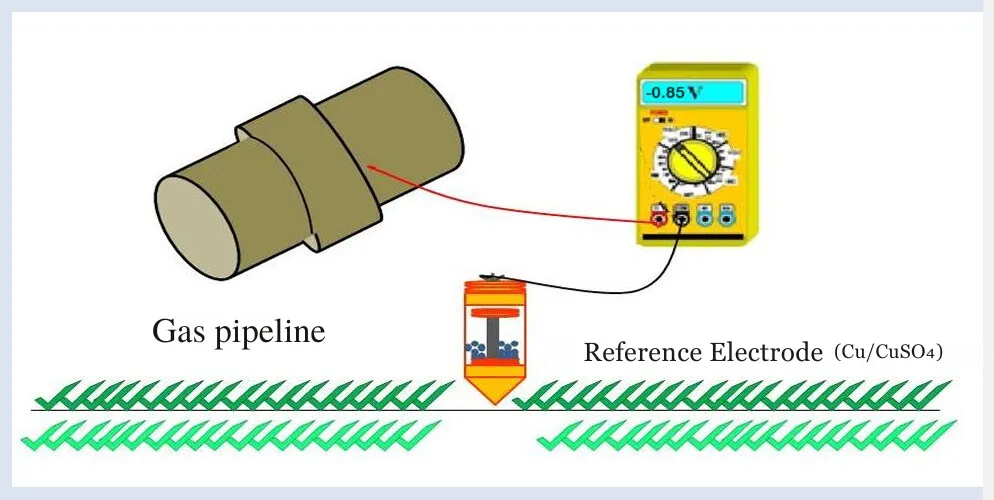

A cathodic protection system works correctly and prevents corrosion of structures when the potential measurements taken comply with certain values. The classic way to measure the potential of a pipe consists of making contact with the pipe at the Potential Taps (TP) and measuring with a voltmeter of high internal impedance with respect to a portable copper sulfate copper reference electrode, located on the ground.

Know and follow cathodic protection criteria

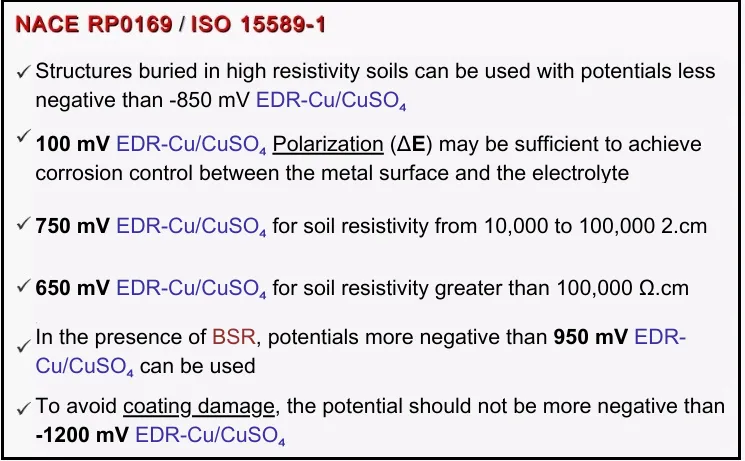

As a first step it is important to know and follow the rules governing the criteria for the operation of CP systems, which works, works correctly and allows corrosion control, when the potential measurements that are made meet certain values. In order to control the corrosion rate of a buried pipeline by means of cathodic protection, the measured potentials must comply with the Protection Criteria reflected in Table 1 of the NACE standard.

Table I. NACE Standards: Performance Criteria for Cathodic Protection Systems.

Potential cathodic protection criteria.

It is important to keep a continuous record of the following data:

- Structure-electrolyte potential.

- Rectifier voltage.

- Galvanic anodes output current.

- Magnitude and direction of current through mitigation links.

- Resistance of buried beds.

- Integrity of rectifiers, insulating joints, electrical bonds, and other physical characteristics associated with the corrosion control system.

Measurement of structure-to-electrolyte potentials

In real potential measurements made in the field, which must be free of IR resistance drops (figure 2), there is an important distance between the position of the reference electrode and the metal from which we want to measure the potential3. On the one hand there is the distance between the reference electrode and the tube, and on the other hand the distance between the nearest coating defect and the vertical of the reference electrode.

How to measure the protection potential?

Figure 2. Potential measurement: structure (pipe)-electrolyte (soil). Vs. Cu/CuSO4 electrode3.

Apply indirect inspection methodologies to pipelines

Classical potential measurements

Classical potential measurements are performed by measuring at the potential taps (PT) with the cathodic protection system in operation and using portable electrodes. These values obtained represent the average of the real potentials of the defects closest to the point of measurement, to which is added the error I x R. Because of this, there is a significant risk that the apparent values are misleadingly adequate, without reaching the real potential necessary for a correct cathodic protection. This method can lead to the false belief that the pipeline is protected when, in fact, the actual potentials do not meet the protection criteria and corrosion can be significant.

On-Off potential measurements

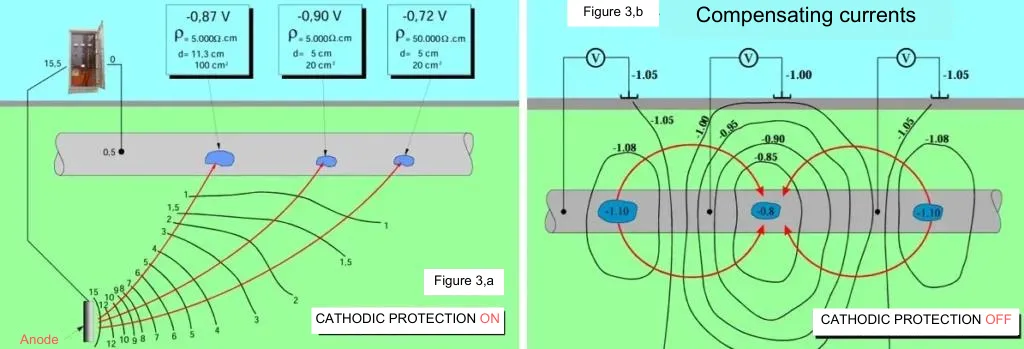

On-Off measurements are made by cyclic cuts of the cathodic protection current in the rectifiers. These measurements can provide a relatively reliable indication in the absence of stray currents. During the ON phase (figure 3a), when the cathodic protection is active, different conditions at each fault, such as soil resistivity, size and surface area of the fault, mean that the actual potential level at each fault can vary3.

Figure 3. On-Off potential measurements3.

At the moment of interrupting the cathodic protection phase OFF (figure 3b), compensation currents are generated that produce a certain I x R error. Although this technique improves the accuracy compared to classical measurements, it is important to take these errors into account to ensure a correct evaluation of the cathodic protection and to avoid significant corrosion in defects that are not adequately protected.

Technological innovations in PC monitoring

After their start-up, these systems must be monitored to evaluate their effectiveness and perform the necessary maintenance. For this purpose, the measurement points of the cathodic protection in the distribution, transport and storage networks are determined during the design phase. By acquiring the pipe-earth potentials of the pipeline to be protected, manual checks at the measuring points or conventional measuring methods can be programmed.

Remote monitoring: Cathodic Protection by Telemetry

Telemetry cathodic protection is an advanced technique used to evaluate the effectiveness of cathodic protection systems in various installations. This technique is based on the use of remote sensors to collect data on the status of cathodic protection and transmit it to a central location. This allows operators to monitor and control cathodic protection systems remotely, facilitating corrective action if necessary and ensuring the integrity of the facility.

Operation of Telemetry in Cathodic Protection

Telemetry for measuring cathodic protection employs sensors and communication devices that collect data on the status of protection systems. This data includes the resistance of the ground current through various materials and coatings, such as earth, structures, pipes, cables, liquid, gaseous and solid fuel storage tanks.

- Remote Sensors: Remote sensors installed at strategic points in the infrastructure continuously measure ground current resistance and other critical parameters. These sensors are capable of detecting variations in the cathodic protection potential, providing accurate information on the system status.

- Data transmission: Data collected by the sensors is transmitted in real time to a central location via wireless communication systems. This transmission allows continuous monitoring of the cathodic protection status, without the need for frequent physical inspections.

- Centralized analysis: At the central location, the data received is analyzed using specialized software. This analysis allows engineers to identify any deviations from normal cathodic protection parameters and make informed decisions on necessary corrective actions.

Applications and benefits

Cathodic protection offers multiple benefits in the management and maintenance of protected infrastructures:

- Continuous monitoring: Allows constant supervision of the cathodic protection status, facilitating early detection of problems and minimizing the risk of structural failure.

- Proactive interventions: The ability to identify and correct problems before they become threats to facility safety significantly reduces the cost and time associated with major repairs.

- Resource optimization: By reducing the need for frequent physical inspections, human and material resources are optimized, improving operational efficiency.

- Improved safety: Constant monitoring and rapid response capabilities contribute to overall infrastructure safety, preventing damage to critical structures and equipment.

In summary, cathodic protection by telemetry is an essential tool to ensure the efficiency and reliability of cathodic protection systems, allowing a more efficient and safer management of industrial installations.

These can be replaced or completed with the installation of electronic devices capable of continuously acquiring the potentials and sending them to a data collection center that automatically analyzes the parameters and, if necessary, fulfills the obligations of remote control of the network by means of alarm signals that allow the anomaly to be identified and quickly resolved.

To improve monitoring efficiency, it is possible to install electronic devices that continuously acquire potentials and send them to a data collection center. This center automatically analyzes the parameters and, if necessary, activates the network telecontrol through alarm signals to quickly identify and resolve any anomalies. This system ensures that the protected equipment maintains its structural and operational integrity.

Why check the effectiveness of cathodic protection?

Checking the correct operation of the cathodic protection system is not only a requirement of international standards, it is an important step that industries must comply with when deciding to install these systems in order to ensure the integrity and durability of metallic infrastructures. A properly operating cathodic protection system prevents corrosion, which can cause serious structural damage and compromise the safety of the facility.

Constant monitoring of the system allows problems involving damage to materials to be detected and corrected, avoiding disastrous failures and costly repairs. In addition, a well-maintained protection system ensures compliance with international regulations and standards, protecting both people and the environment from the adverse effects of corrosion.

The most important reason to monitor cathodic protection is to make sure that corrosion is under control. When a structure corrodes, leaks can occur, product can be lost, and structural damage can occur. There is also public concern about safety and environmental damage. For this reason, regulations have been enacted in many industries and countries ensure that structures containing hazardous products are adequately protected to reduce the risk to the public and environment.

Conclusion

Cathodic protection is an essential tool to prevent corrosion in metallic components exposed to electrically conductive environments. Its effectiveness depends on the correct application and continuous monitoring of the implemented systems. Through data acquisition and analysis, anomalies can be quickly identified and resolved, ensuring the continuous protection of critical infrastructures.

References

- Pietro Florentina; Protección Catódica Pasiva y Activa.

- Jazmín del R. Torres Hérnandez, Ebelia Del Angel Meraz, Lucien Veleva; “Evaluación de un sistema de protección catódica de un gasoducto enterrado”; Rev. LatinAm. Metal. Mat. 2017; 37 (1): 19-26.

- Adrián Gomila Vinent; Control, mantenimiento y televigilancia de la protección catódica de tuberías de agua de acero.

FAQs on the efficiency of cathodic protection

1.What parameters determine the efficiency of a cathodic protection system?

The efficiency of a cathodic protection system is measured by the protection potential between the metal structure and a reference electrode, such as Cu/CuSO₄. The values must comply with standards such as NACE SP0169 or ISO 15589. Polarization, applied current density, and potential uniformity along the protected structure are also evaluated.

2. How often should cathodic protection parameters be measured?

Cathodic protection system measurements should be performed at varying frequencies depending on the type of system and environment. Monthly or quarterly checks are recommended for impressed current systems, while galvanic systems can be checked annually. Measurements should also be taken after maintenance or repairs.

3. What instruments are used to measure the efficiency of cathodic protection?

To evaluate the efficiency of cathodic protection, high-impedance voltmeters, reference electrodes (Cu/CuSO₄, Ag/AgCl), current meters, and remote monitoring systems are used. This equipment allows verification that potentials are maintained within the appropriate range and detection of possible faults or continuity losses.