Introduction

One of the main causes of accidents in industrial facilities is pressure ; which, if not controlled, can cause leaks, explosions and fires. In recent years, technological advances in the development of IoT sensors offer a promising solution to improve security and control this variable in Oil & Gas facilities.

The oil industry is one of the most important in the world, but it is also one of the most dangerous. Accidents at oil facilities can cause environmental damage, economic loss, and loss of life.

In this article, we will explore how IoT (Internet of Things) sensor technologies are transforming the way pressure is managed in Oil & Gas facilities. We will highlight their importance in managing risk and improving operational efficiency.

Also presented are some interesting facts, revealing percentages, inspiring success stories, names of influential personalities and the latest innovations in this exciting convergence of technology and the oil industry.

IoT sensors and their role in pressure control

They are electronic devices that collect data from the environment and send it over the Internet; They are used in a wide range of applications, including industry, agriculture, healthcare and home. In the case of the oil & gas industry, IoT sensors are used to collect data on pressure, temperature, flow and other key parameters of the facilities.

Sensors are used to monitor pressure in Oil & Gas installations in several ways. One way is to detect variations, when a change in this variable occurs, the sensor sends an alert signal to the operators.

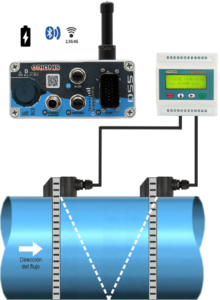

Another form of control is to use flow detectors; which measure the flow of fluids through pipes and other systems. If the flow is too high or too low, the sensor sends an alert to operators. In figure 1, the Detecta-PQ IoT sensor is shown, for monitoring and control of flows and pressures in the network1.

Importance of pressure control

Pressure is a critical variable in petroleum facilities; oil and gas production, transportation and storage processes require precise control of this variable.

Within industrial processes, the measurement and control of this variable become essential to achieve continuous production and have safe operating conditions. Any container or pipe has a maximum operating pressure and exceeding it can cause the destruction of the equipment and put personnel in a risk situation, especially when flammable or corrosive fluids are involved. In this sense, both the control and measurement with great precision of this variable are as important as extreme security.

The benefits of sensors for pressure control

These devices offer a series of benefits for pressure control in oil & gas installations. These benefits include:

- Improved safety: They help detect and prevent accidents.

- Operational Efficiency: Improve operational efficiency by reducing downtime and maintenance costs.

- Reduction of emissions: They reduce polluting emissions by improving the efficiency of processes.

Success story in the use of digital technology

The company “Schlumberger, one of the largest companies providing services to the oil industry worldwide, has developed a series of technologies to close the gap in the Oil Industry in the field of Digital Transformation, considering that this industry has not been moved with the same speed as others. In this sense, Schlumberger presented one of the technological offers that Schlumberger has to cover the gaps that exist in the digital transformation of an oil field: AGORA Gateway 2 “

IoT technological innovations in the oil industry

- Nanotechnology sensors: They are extremely sensitive and accurate in detecting minute changes in pressure and providing real-time data for faster and more accurate decision making.

- Self-powered Wireless Sensors: They operate autonomously without the need for cables or frequent battery replacement; which reduces maintenance costs and increases efficiency.

- Integration with advanced analytics platforms: The combination of these sensors with advanced analytics platforms, such as artificial intelligence and machine learning, allows for greater prediction and optimization capacity. These platforms can identify patterns and trends that are difficult to detect manually.

- Smart self-calibrating sensors: They are state-of-the-art and self-calibrating, meaning they can automatically adjust their measurements to ensure accuracy over time without human intervention.

- Mesh Sensor Networks: These are systems that can communicate with each other and transmit data through a mesh of connections. This improves redundancy and reliability of data communication, even in harsh environments.

- Remote sensors and drones: This combination allows for broader and more detailed monitoring of Oil & Gas facilities.

- Sensors for extreme environments: The oil & gas industry often operates under conditions of high pressures and extremely low or high temperatures, they are designed specifically for these extreme conditions, they are a critical innovation.

- Advanced Cyber Security: Innovations in this field include advanced encryption and threat detection technologies to protect data and the integrity of information systems.

- Leak Detection Sensors: Detect oil or gas leaks in real time, allowing immediate response to potentially dangerous situations.

- Improved user interface: The innovations are not only limited to the sensors themselves, but also to the user interfaces. Improved apps and dashboards give operators a more intuitive and richer view of data.

Conclusion

IoT sensors have proven to be an invaluable tool in pressure management in Oil & Gas facilities. Their ability to improve safety, reduce accident risks, optimize operational efficiency and be endorsed by influential personalities has driven their adoption across the industry. Ultimately, the implementation of sensors is a fundamental step towards a safer, more efficient and sustainable future in the oil industry.

“Discover the safe and efficient future of Oil & Gas with IoT!”

References

- Schlumberger – Digital Transformation – AGORA SUN, 11/24/2019 – https://spe-ecuador.org/schlumberger-transformacion-digital-agora

- Cognizant in Spain – https://www.cognizant.com/es/es/about-cognizant.