Table of Contents

- The current role of Integrity Engineers

- What do Integrity Engineers provide to industry today?

- La digitalización applied to asset integrity

- Digital Skills in Integrity Engineers

- Digital transformation in asset management

- Digital applications for Industrial Integrity

- Training the digital Integrity Engineer

- Challenges for the Digital Integrity Engineer

- Conclusion

- References

- Frequently Asked Questions (FAQs)

Integrity engineering has transcended conventional methods and is moving toward a predictive digital approach. Power plants, refineries, pipelines, and storage terminals are migrating toward hyperconnected ecosystems where data, sensors, and advanced analytics redefine how operational reliability is protected. In this new industrial environment, integrity engineers assume a decisive role in the digital evolution.

The professional profile evolves from reactive inspection toward risk-based decision-making, supported by IDMS/APM platforms, continuous monitoring, and degradation models. IDMS (Integrity Data Management Systems) and APM (Asset Performance Management) centralize inspection, condition, failure, and criticality information, integrating it into predictive analyses that support timely and accurate decisions.

Thus emerges a new generation of integrity engineers who combine API/ASME/NACE/ISO standards with digital skills and operational intelligence to maintain assets that are safe, efficient, and within their operating windows.

The current role of Integrity Engineers

Integrity engineers are no longer limited to applying standards or evaluating damage mechanisms. Today, they are hybrid professionals integrating engineering, data, and asset management to make decisions aligned with operational reliability. This evolution requires mastering fields that previously operated independently but now converge within a technical-digital approach:

- Traditional engineering (API, ASME, NACE, DNV, ISO)

- Data analytics and industrial monitoring

- Asset management under ISO 55001

- Risk-based inspection strategies (RBI)

- Fitness-For-Service evaluations (API 579/FFS-1)

- Digital platforms such as IDMS/APM

Integrating these domains is essential to ensure the mechanical and operational integrity of high-value assets such as tanks, pressure vessels, piping, furnaces, and rotating equipment throughout their life cycle, both in operation and preservation.

This transformation of the role requires competencies ranging from API 510/570/653, corrosion and damage mechanisms, to the management of predictive models, IoT sensors, and digital twins. The discipline has evolved and now demands professionals capable of excelling in industrial environments increasingly dependent on data, advanced analytics, and intelligent systems.

A recent audiovisual resource from Energy Insider clearly explains the modern functions of the integrity engineer: evaluating asset conditions, reviewing inspection data, applying standards, managing risks, recommending interventions, and sustaining operational reliability. The material highlights technical responsibility, strategic roles, and the importance of evidence-based decision-making.

What does an integrity engineer do?

Video: https://www.youtube.com/watch?v=Eq1dXwTFs28&t=64s

What Does an Integrity Engineer Do?

What do Integrity Engineers provide to industry today?

Integrity engineers provide what no technology can replace: technical judgment with practical sense. They transform dispersed data into strategic decisions, detect risks before they manifest, and maintain operational reliability.

This contribution is not limited to regulatory compliance; it balances technical standards, analysis, field experience, and professional judgment to ensure plants operate safely without incidents that could lead to significant financial losses.

Contemporary technical literature emphasizes that the modern integrity engineer must combine regulatory experience with advanced analytical capabilities, risk-based prioritization, and Fitness-For-Service evaluations. Additionally, they must integrate operational data, degradation trends, and predictive models to make increasingly reliable and timely decisions in complex industrial environments.

La digitalización applied to asset integrity

Digitalization is not merely the use of technological tools; it involves integrating operations, data, regulations, and processes into a unified operational environment. Integrity engineers can no longer rely solely on standards and inspection techniques: they must understand digital systems where these elements converge and are managed.

- Industrial IoT

- Cloud platforms

- Operational intelligence

- Analytics and machine learning

- Digital integrity management platforms

This transition enables a shift from reactive approaches to predictive strategies based on reliable and traceable data, reducing risk uncertainty and strengthening operational resilience.

Key elements of digitalizatión

The digital integrity specialist is trained to understand how data is structured, validated, and converted into actionable information. This requires mastery of:

- IIoT sensors and connectivity

- Integration of operational and technical data

- Data quality, traceability, and governance

- Analytical models applied to degradation

- Digital twins for condition monitoring

- Digital integrity management systems as the core of management

These technologies are critical because they underpin intelligent environments where reliability depends on both engineering expertise and the ability to interpret data to anticipate problems.

Digital Skills in Integrity Engineers

Industrial digitalization redefines the professional profile. Integrity engineers must interpret data, operate digital platforms, and apply predictive criteria to reduce risk uncertainty.

Digital skills bridge the gap between operational data and decisions aligned with ISO 55001 and asset management objectives.

Priority technical digital skills

- Operational mastery of IDMS/APM platforms

- Use of predictive algorithms and models

- Interpretation of data from IIoT sensors

- Generation of reliable dashboards and indicators

- Application of digital twins to model degradation

- Automation of analysis through scripting (Python, MATLAB)

- Understanding industrial cybersecurity fundamentals

These competencies allow large volumes of data to be transformed into operational intelligence that optimizes asset life.

Strategic and collaborative skills

Integrity engineers, beyond regulatory knowledge and field experience, must incorporate strategic skills that facilitate the integration of technology in operational environments. This includes communicating complex analyses to non-technical teams, justifying data-driven decisions, and leading the adoption of digital tools while maintaining focus on safety and mechanical integrity.

Coordination with operations, maintenance, and IT is essential to ensure digital solutions add value and integrate sustainably.

Digital transformation in asset management

Integrity management has moved beyond static processes; digital transformation integrates real-time data, failure history, predictive models, and FFS assessments within a single decision-making framework.

Centralized predictive systems consolidate this information and function as the “digital brain” of the asset, driving faster, more accurate decisions aligned with availability objectives.

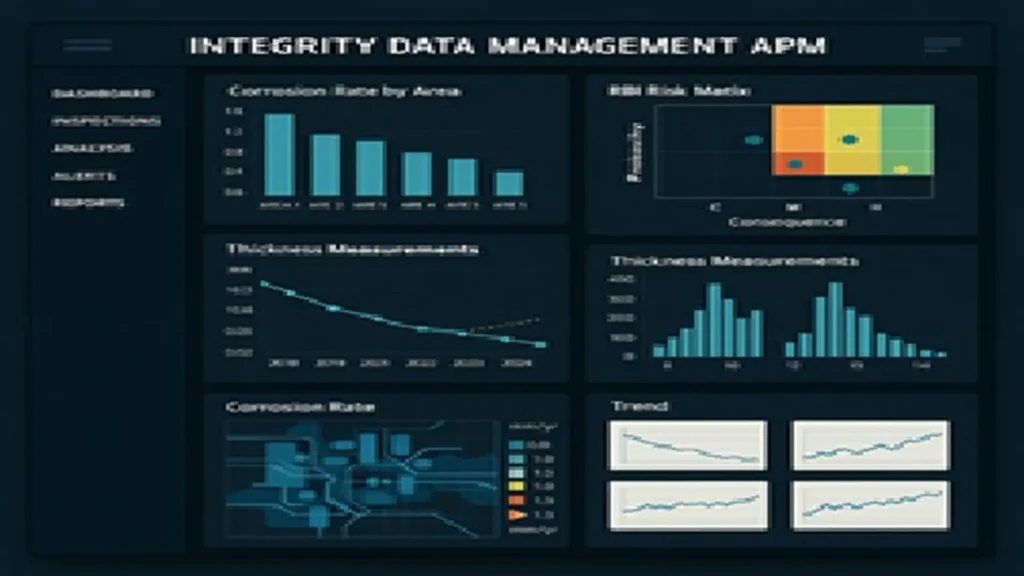

Dashboard IDMS/APM: Integrity Tool for Risk and Degradation Assessment.

Operational intelligence in critical assets

Operational intelligence is a versatile tool for integrity engineers. By combining degradation history, real operational conditions, and advanced analytics, it is possible to anticipate failures with greater accuracy.

Methods such as machine learning, signal analysis, trending, and probabilistic models enrich technical judgment, enabling faster and more timely diagnostics. This integration enhances the engineer’s capacity to prioritize risks, optimize resources, and improve operational continuity.

Benefits of digitalization in integrity

Digitalization provides the following tangible benefits:

- Fewer invasive inspections

- Improved risk-based prioritization

- Greater technical traceability

- Faster response to degradation

- Extended equipment life

Integrity thus evolves into an intelligent system that supports safer operations.

Digital applications for Industrial Integrity

The modern integrity engineer acts as the technical architect of digitalization, integrating sensors, historical data, and advanced analytics to design strategies that reduce uncertainty and increase reliability. This convergence transforms asset management into a proactive system, where digital integrity platforms centralize critical information and facilitate evidence-based decisions.

Notable solutions include those developed by AsInt, which integrate integrity modules (IDMS), asset performance (APM), and risk analysis (RBI) in digital systems that allow risk prioritization and degradation scenario forecasting with greater precision.

Practical use of IDMS and APM in critical assets

IDMS/APM systems are central tools for integrity engineers, consolidating key information such as inspections, thicknesses, findings, failures, and RBI criticality. Using these systems does not replace technical experience; it reinforces it. They allow the identification of operational trends, generation of early warnings, and provision of data to predictive models that enhance decision-making accuracy. The result is consistent, traceable management aligned with reliability principles and risk analysis.

Intelligent continuous monitoring

Continuous monitoring does not substitute the judgment of the integrity engineer; it extends technical surveillance capabilities. Vibration, corrosion, pressure, and temperature sensors detect deviations before they escalate into failures. When integrated into analytical platforms, engineers validate anomalous patterns, adjust inspection frequencies, and make predictive decisions, reducing unplanned downtime and enhancing asset availability.

Training the digital Integrity Engineer

The current industry requires professionals capable of integrating classical engineering, asset management (ISO 55001), digital technologies, and data analysis. Modern training combines regulatory foundations, simulation with real data, and the operation of digital platforms that support risk-based decisions.

Although most integrity engineers come from other sciences such as mechanical, materials, chemical, or petroleum engineering, specialized postgraduate programs in asset integrity and pipeline integrity exist worldwide, evidencing the establishment of this discipline as a distinct professional role within the energy and industrial sector.

According to international technical sources, integrity engineering is recognized as a formal discipline dedicated to the design, analysis, inspection, and life-cycle management of critical assets. This framework supports the role’s evolution toward advanced digital skills and integration with predictive platforms and asset management systems.

Global educational offerings also include technical specializations focused on risk assessment, corrosion, predictive analytics, continuous monitoring, and data-driven decision-making—essential competencies for ensuring the reliability and safety of modern industrial assets.

Challenges for the Digital Integrity Engineer

Engineers face key challenges: data quality, platform integration, digital gaps, OT/IT security, and resistance to change. Additionally, they must justify the return on investment of each technological solution. Overcoming these challenges requires technical leadership, strong digital culture, and a risk-based vision that enables sustainable decision-making.

Conclusion

Integrity engineers consolidate as architects of digital reliability. They integrate technical standards, digital skills, digital culture, and operational intelligence to manage assets with precision and foresight. Mastery of IDMS/APM, advanced analytics, and continuous monitoring enables leadership in industrial digital transformation. Adopting this approach converts asset management into a predictive and strategic process, providing high-impact technical and economic decisions in increasingly complex industries.

References

- Peter Trampus; Vjera Krstelj; Giuseppe Nardoni. (2019). NDT integrity engineering – A new discipline. Sciencedirect

- https://cognascents.com/integrity-engineer-2/

- https://www.planitplus.net/JobProfiles/View/944/145

Frequently Asked Questions (FAQs)

What digital skills does an integrity engineer need?

Data analytics, IDMS/APM, IoT, dashboards, failure prediction, and digital culture.

What differentiates a traditional engineer from a digital engineer?

The digital engineer integrates data and sensors for predictive, real-time decision-making.

What is the purpose of an IDMS system in industrial integrity?

It organizes data, generates alerts, and enables traceable integrity management.

Which technologies drive industrial digital transformation?

AI, IoT, digital twins, predictive analytics, and APM systems.

How does continuous monitoring improve integrity?

It detects anomalies before failure, reduces downtime, and optimizes interventions.