Table of Contents

- From discovery to digitalization

- Fundamentals of industrial radiography

- Transition to digital: The game changer in NDT imaging

- Real-Time Radiography and the Rise of Computed Tomography (CT)

- X-ray and robotics: inspection at industrial speed

- Industry success stories and technology leaders

- Challenges and opportunities in the digital era

- The future of industrial radiography: digital intelligence

- Conclusions

- References

- Frequently Asked Questions (FAQs)

- What is the difference between ISO 9712 and SNT-TC-1A certifications in industrial radiography?

- What is Corrosion Under Insulation (CUI) and why is digital radiography essential for its detection?

- Why is direct radiography (DR) considered safer than traditional film radiography?

- How is industrial radiography integrated within the Industry 4.0 concept?

- What are the roles of Level I, II, and III in industrial radiography?

The history of industrial radiography began in 1895, when Wilhelm Conrad Röntgen discovered X-rays and forever changed the way humanity could observe the invisible. What began as a scientific curiosity quickly became an essential tool for medicine and, shortly thereafter, for industry.

At the beginning of the 20th century, engineers realized that this form of radiation could pass through metal as easily as human tissue, revealing hidden defects that were impossible to detect with the naked eye. This breakthrough marked the beginning of the industrial use of ionizing radiation, which made it possible to analyze metallic materials without damaging them and laid the foundation for future inspection techniques.

After World War II, radiography became a cornerstone of quality control in manufacturing, refineries, and pipeline construction. Since then, this technique has been essential for verifying structural integrity and maintaining rigorous quality control standards in the most demanding industrial processes.

From discovery to digitalization

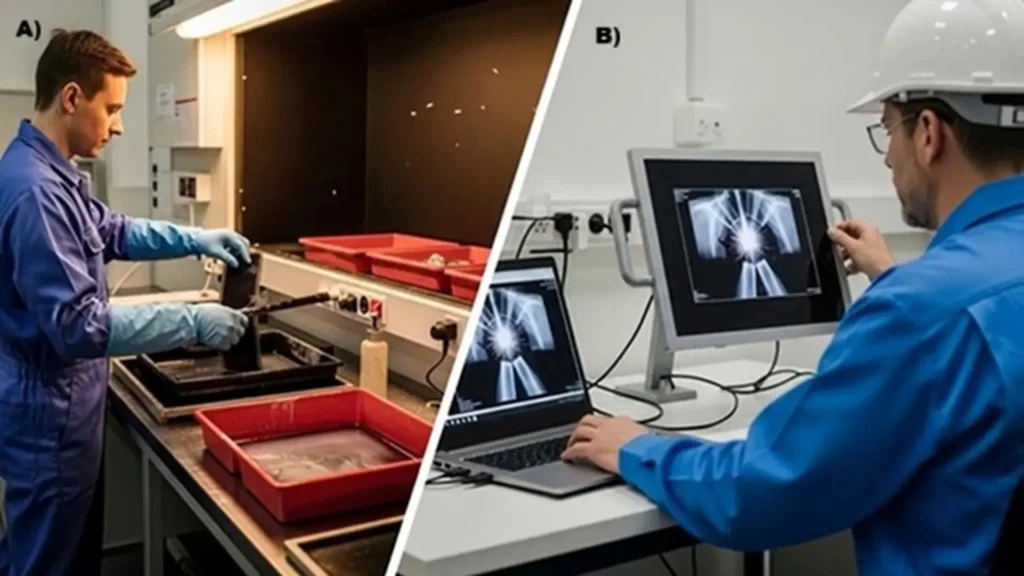

For decades, film inspection dominated the field, offering reliable results, but requiring time and experience. Inspectors worked in darkrooms, surrounded by chemicals and X-ray films, honing their eyesight to interpret the shades of gray that marked the difference between safety and risk. However, the method had limitations: long processing times, increased exposure to radiation, and the complexity of storing and retrieving records.

The limitations outlined above drove innovation. The emergence of computed radiography introduced phosphor imaging plates that digitized the process while maintaining image integrity. Soon after, direct radiography replaced plates with digital detectors, allowing immediate visualization and data transfer. What once took hours could now be done in minutes, with higher precision and lower exposure.

The journey from glass plates to digital pixels reflects more than a technological evolution; it represents a continuous pursuit of safer, faster, and smarter ways to The emergence of computed radiography introduced phosphor imaging plates that digitized the process while maintaining image integrity. Soon after, direct radiography replaced plates with digital detectors, allowing immediate visualization and data transf.er.ensure asset integrity across the world’s most critical infrastructures.

Fundamentals of industrial radiography

Industrial radiography is one of the most trusted techniques in non destructive testing, allowing engineers to “see through” solid materials without causing damage. It provides vital insights into the internal structure of welds, castings, and components that operate under high pressure or temperature, making weld inspection a critical step in preventing defects and ensuring long-term reliability.

X-ray vs gamma radiography

The core principle of radiography lies in exposing a material to a controlled source of ionizing radiation. In X-ray radiography, radiation is produced electrically, making it easier to regulate intensity and switch on or off as needed.

This method is ideal for workshops, laboratories, and controlled environments. Gamma radiography, in contrast, uses radioactive isotopes such as Iridium-192 or Cobalt-60 as its source, providing greater portability for field inspections in remote or confined areas. Each technique has its strength: X-rays offer better control and image quality, while gamma rays excel in accessibility and penetration power.

Image formation and interpretation

When radiation passes through a component, denser areas absorb more energy, creating lighter zones on the image, while thinner or less dense regions appear darker. This variation in contrast allows inspectors to detect cracks, porosity, inclusions, and corrosion. Skilled interpretation, supported by advanced image analysis, is essential; a well-trained eye can distinguish between harmless indications and true defects that could compromise asset integrity and long-term reliability.

Safety and regulatory framework

Because radiography involves ionizing radiation, safety is paramount. Strict dose monitoring, shielding practices, and controlled work zones protect personnel and the environment. International standards such as ISO 9712 and ASNT SNT-TC-1A ensure that only qualified and certified professionals perform these inspections, maintaining consistency and reliability across industries worldwide.

Transition to digital: The game changer in NDT imaging

The move from traditional film to digital imaging marked a defining shift in industrial radiography. For decades, film radiography demanded patience—hours of exposure, darkroom development, and manual interpretation. Digital technologies transformed that reality, introducing faster, safer, and more accurate ways to capture and analyze radiographic data.

Computed Radiography (CR)

Computed radiography was the bridge between analog and digital inspection. Instead of film, it uses a phosphor imaging plate that captures the radiation image. The plate is then scanned by a laser reader, converting the information into a digital file.

Although CR still requires some manual steps, it drastically reduces the use of chemicals and allows adjustment of parameters such as brightness or contrast without the need for repeat exposure, ensuring continuous improvement in the quality control of radiographic images.

In addition, the efficiency of the process considerably reduces the direct handling of ionizing radiation sources, increasing occupational safety and reducing the exposure of technical personnel.

Direct Radiography (DR)

Direct radiography took digitization a step further by using flat detectors that capture and display images instantly on a computer. Inspectors can review, magnify and evaluate the results in a matter of seconds. DR offers higher resolution, shorter exposure time and superior consistency, making it an ideal tool for field inspections where speed, accuracy and efficient data storage management are crucial to maintaining operational continuity and quality of the digital record.

Benefits over film

Digital radiography delivers clear advantages: faster turnaround, reduced radiation exposure, and simplified archiving. It also lays the foundation for automated inspection, where digital data can be captured, processed, and analyzed without manual film handling. Images can be stored, shared, and interpreted remotely, facilitating collaboration and traceability. Additionally, eliminating film and chemicals offers significant environmental benefits.

A notable example of this transformation can be seen in the work of Carestream’s NDT Division, which has guided several petrochemical plants and pipeline inspection programs through the transition from film to digital workflows. Their advanced digital detectors have significantly improved the accuracy and efficiency of pipeline and weld inspection, particularly in detecting defects and corrosion under insulation (CUI) across extensive pipeline networks.This evolution not only enhances operational reliability but also aligns pipeline inspection practices with the broader digital transformation of industrial asset management.

The shift to digital radiography represents more than a technological leap, it is a redefinition of reliability, efficiency, and sustainability within the modern non-destructive test landscape.

Real-Time Radiography and the Rise of Computed Tomography (CT)

Modern industrial inspection has entered an era where immediacy and precision define quality assurance.

The following video illustrates how real-time digital radiography is applied during pipeline weld inspection, a practice that reflects the evolution toward safer and more efficient systems within Industry 4.0. Video courtesy of TechCorr USA, publicly available on YouTube for educational and informational purposes.

Real-time X-ray imaging: Revolutionizing pipe inspection.

Real-time radiography has become a vital tool in on-stream inspection programs, allowing operators to assess components without interrupting operations. By transmitting X-rays or gamma rays through an object and capturing the interaction on a phosphor screen or flat-panel detector, the system produces a live image that can be viewed instantly.

This capability helps engineers make quick, informed decisions about weld integrity, corrosion progression, or foreign object intrusion, reducing downtime and improving process reliability.

In parallel, computed tomography (CT) has emerged as one of the most powerful imaging tools available to the NDT field. CT reconstructs hundreds or even thousands of two-dimensional radiographs into a detailed three-dimensional model. This volumetric view enables precise visualization of internal geometries, porosity distribution, or micro-cracks, critical for sectors such as aerospace, where lightweight alloys and additive-manufactured parts require flawless integrity.

However, these advances also present challenges. CT systems require high operating costs, powerful radiation sources, stable rotation mechanisms and large data storage capacity. The volume of information generated by each scan requires robust and secure data storage solutions capable of preserving the integrity of files for subsequent comparative analysis or technical audit.

In addition, analysis of the enormous amount of information generated requires specialists with expertise in image physics and digital reconstruction techniques. Even so, the combination of real-time visualization and 3D modeling is transforming radiography from a diagnostic tool to a predictive resource for industrial integrity management.

X-ray and robotics: inspection at industrial speed

As industrial facilities grow larger and more complex, the need for faster and safer inspection has driven the adoption of automated radiographic testing (ART) and robotic imaging systems. These technologies merge robotics, digital sensors, and advanced software to deliver accurate and repeatable results through automated inspection systems that eliminate human exposure to radiation and minimize operational downtime.

ART and motion control systems

Automated radiography platforms use robotic crawlers equipped with CMOS or flat-panel detectors that move along pipelines, vessels, or insulated structures. These systems emit low-dose X-rays while simultaneously capturing high-resolution digital images.

The result is a continuous radiographic map that reveals wall thinning, internal corrosion, or cracking beneath insulation, issues that would traditionally require stripping or manual scanning.

Case example

A refinery operator implementing automated X-ray mapping on aboveground pipelines achieved remarkable gains. By deploying a semi-autonomous crawler, the inspection team captured detailed digital profiles of large pipe sections while the system remained in service. The images were instantly processed and displayed for analysis, demonstrating how automated inspection can locate corrosion cells with precision and consistency, without disrupting production or requiring line shutdowns.

The result was a significant reduction in exposure risk and a decrease in inspection time to less than half compared to conventional methods, tangibly raising the operational efficiency of the system and improving asset availability.

Future trends

The next evolution in ART lies in the integration of artificial intelligence, digital twin technology, and automated inspection analytics that continuously learn from historical defect data. AI-assisted image analysis and recognition will automatically classify indications and compare them against historical defect libraries, improving accuracy and consistency.

When paired with cloud-based platforms, these systems will synchronize inspection data with asset digital twins, enabling predictive maintenance strategies. This convergence of robotics, analytics, and radiography is propelling the industry toward a future where inspections are not only faster and safer but also continuously smart aligning with the goals of Industry 4.0.

Industry success stories and technology leaders

The evolution of industrial radiography owes much to the vision and innovation of key players that have transformed traditional inspection into digital discipline. Among them, Carestream’s NDT Division stands as a benchmark of technological adaptation. With decades of expertise in medical imaging, the company successfully transitioned its knowledge to industrial applications, developing robust digital detectors and imaging software designed for harsh environments. Their portable systems have redefined field radiography, offering instant, high-resolution results for weld inspection, corrosion mapping, and CUI detection, particularly in the petrochemical and energy sectors.

Beyond individual excellence, collaboration has been a powerful driver of progress. MISTRAS Group, GE Inspection Technologies, and RT Alliance have built strong ecosystems that integrate hardware, software, and services. Their work promotes interoperability and data sharing, enabling end users to combine multiple inspection techniques (radiography, ultrasound, and thermography) into a unified digital framework. This approach not only improves accuracy but also strengthens predictive maintenance capabilities.

Meanwhile, a new generation of startups and robotics integrators is reshaping the NDT landscape. Companies specializing in autonomous crawlers, compact X-ray generators, and AI-driven image analytics are bridging the gap between radiography, data science, and automation. Their contributions are democratizing access to advanced inspection tools and setting the stage for a new era of smart, connected radiographic systems.

Challenges and opportunities in the digital era

The digital transformation of radiography has opened up a range of extraordinary possibilities, but it also poses new challenges. The move from film to fully digital workflows generates enormous volumes of data that must be securely stored, processed and interpreted.

Data storage has become a critical part of the modern radiography ecosystem, not only for its logistical function, but for its role in the traceability, auditing and protection of sensitive information from each inspection. Managing this information requires robust cybersecurity protocols that protect sensitive data and ensure regulatory compliance, especially in industries where inspection results are directly tied to safety and operational reliability.

In this new digital environment, the responsible management of ionizing radiation remains an essential pillar, integrating advanced monitoring and control systems to protect people and ensure traceability of processes.

Another important challenge lies in the human factor. The new generation of inspectors must have hybrid skills, combining traditional nondestructive testing expertise with knowledge in data analysis, image processing and information technology. Training and certification programs are adapting to this new reality, promoting multidisciplinary competence. At the same time, regulatory bodies are updating standards and guidelines for validating electronic files, automatic defect detection and cloud-based workflows.

Although demanding, these changes represent an unprecedented opportunity to improve efficiency, traceability and confidence in inspection data throughout the entire asset lifecycle, reinforcing the role of quality control as a transversal axis in the digitization of industrial processes, aligning with the principles of Industry 4.0, where interconnection, automation and data intelligence become pillars of industrial performance.

The future of industrial radiography: digital intelligence

Industrial radiography is rapidly moving toward a data-driven, predictive model that aligns with the broader vision of Industry 4.0, where automated inspection and image analysis combine to enhance reliability and reduce human error. The convergence of radiographic testing with artificial intelligence and digital twins is redefining how assets are inspected and managed. AI algorithms are already capable of recognizing defect patterns, measuring wall thickness variations, and correlating findings with historical performance data, transforming inspection from a reactive activity into a proactive, analytical discipline.

Predictive analytics allows maintenance teams to anticipate degradation trends, plan interventions more efficiently, and minimize unplanned shutdowns. As smart sensors and IoT networks become more integrated into inspection equipment, radiography is evolving into a continuous monitoring system rather than a periodic assessment.

This integration allows field-collected data to connect directly to integrity management platforms, improving decision making with near real-time information. Advances in data storage and interoperability are allowing radiographic images and historical records to be integrated into broader digital ecosystems, where information flows seamlessly between inspection, maintenance and predictive analytics.

The result is a smarter, safer, and more connected industrial ecosystem where radiography not only detects flaws but also helps prevent them.

Conclusions

Industrial radiography remains a cornerstone of asset integrity assurance, even as its tools and techniques continue to evolve. Its modernization, from film to digital and now to smart systems, mirrors the transformation of the global energy and manufacturing sectors toward greater efficiency and reliability.

In today’s connected world, radiography is more than a means of revealing internal flaws; it is a source of continuous insight that supports predictive maintenance, sustainability, and safety. Industrial radiography is no longer just about seeing inside metal; it’s about seeing the future of reliability.

References

- International Organization for Standardization (ISO). (2021). ISO 9712:2021 – Non-destructive testing — Qualification and certification of NDT personnel. Geneva: ISO. Retrieved from https://www.iso.org/standard/75614.html

- Cao, Q., et al. (2022). A Review of Corrosion under Insulation: A Critical Issue in the Oil and Gas Industry. Metals, 12(561). Retrieved from https://dspace.mit.edu/bitstream/handle/1721.1/141822/metals-12-00561-v2.pdf

- Corrosionpedia. (2020, May 28). A Look at Digital Radiography for Corrosion Inspection. Retrieved from https://www.corrosionpedia.com/a-look-at-digital-radiography-for-corrosion-inspection/2/7075

- Quality Magazine. (2023). Certification Standards within Nondestructive Testing: Options for NDT Personnel. Retrieved from https://www.qualitymag.com/articles/97847-certification-standards-within-nondestructive-testing-options-for-ndt-personnel

- Natural Resources Canada. (2024). Standards Framework for the NDT Certification Program. Retrieved from https://natural-resources.canada.ca/science-data/non-destructive-testing/standards-framework-ndt-certification-program

Frequently Asked Questions (FAQs)

What is the difference between ISO 9712 and SNT-TC-1A certifications in industrial radiography?

ISO 9712 is an international standard that certifies nondestructive testing (NDT) operators through theoretical, practical, and experience-based exams. SNT-TC-1A is a U.S. guideline issued by ASNT that allows companies to internally certify their operators, with flexible criteria based on company policy.

What is Corrosion Under Insulation (CUI) and why is digital radiography essential for its detection?

CUI occurs when corrosion develops on metals covered by thermal insulation or coatings, where moisture and condensation promote deterioration. Digital radiography (DR) allows inspection without fully removing insulation, detecting internal defects with high resolution and reducing handling risks.

Why is direct radiography (DR) considered safer than traditional film radiography?

DR uses electronic detectors that capture images in real time, reducing the need for prolonged X-ray or gamma exposures. This lowers radiation exposure for operators and nearby personnel, enhancing both safety and process efficiency.

How is industrial radiography integrated within the Industry 4.0 concept?

Industrial radiography integrates through automation, smart sensors, real-time data analysis, and IoT connectivity. This enables faster, predictive, and more accurate inspections, optimizing maintenance, reducing failures, and generating data-driven decision-making.

What are the roles of Level I, II, and III in industrial radiography?

Level I: Performs tests under supervision, following established procedures.

Level II: Interprets results, sets up equipment, and authorizes reports, operating with technical autonomy.

Level III: Develops procedures, trains personnel, audits, and ensures quality of inspection programs.