Table of Contents

- The humanoid robot enters the industry

- What defines an industrial humanoid robot?

- The challenge: Critical problems in modern industry

- The solution: The humanoid robot as a technical response

- Control and perception architecture

- Applications where the problem is greatest

- Examples of robotics and automation in industry today

- Success case: Humanoid robotics in industrial operation

- Challenges for its adoption

- Evolution of physical automation

- Conclusions

- References

- Frequently Asked Questions (FAQs)

- What is an industrial humanoid robot?

- What industrial problems does humanoid robotics solve?

- Why are torque and dynamic control key?

- Where does a humanoid robot provide the greatest value?

- What are the challenges for its adoption?

- How is it integrated into current industrial systems?

- Do humanoid robots replace personnel?

- Which sectors benefit most from this technology?

- Is humanoid robotics already a mature technology?

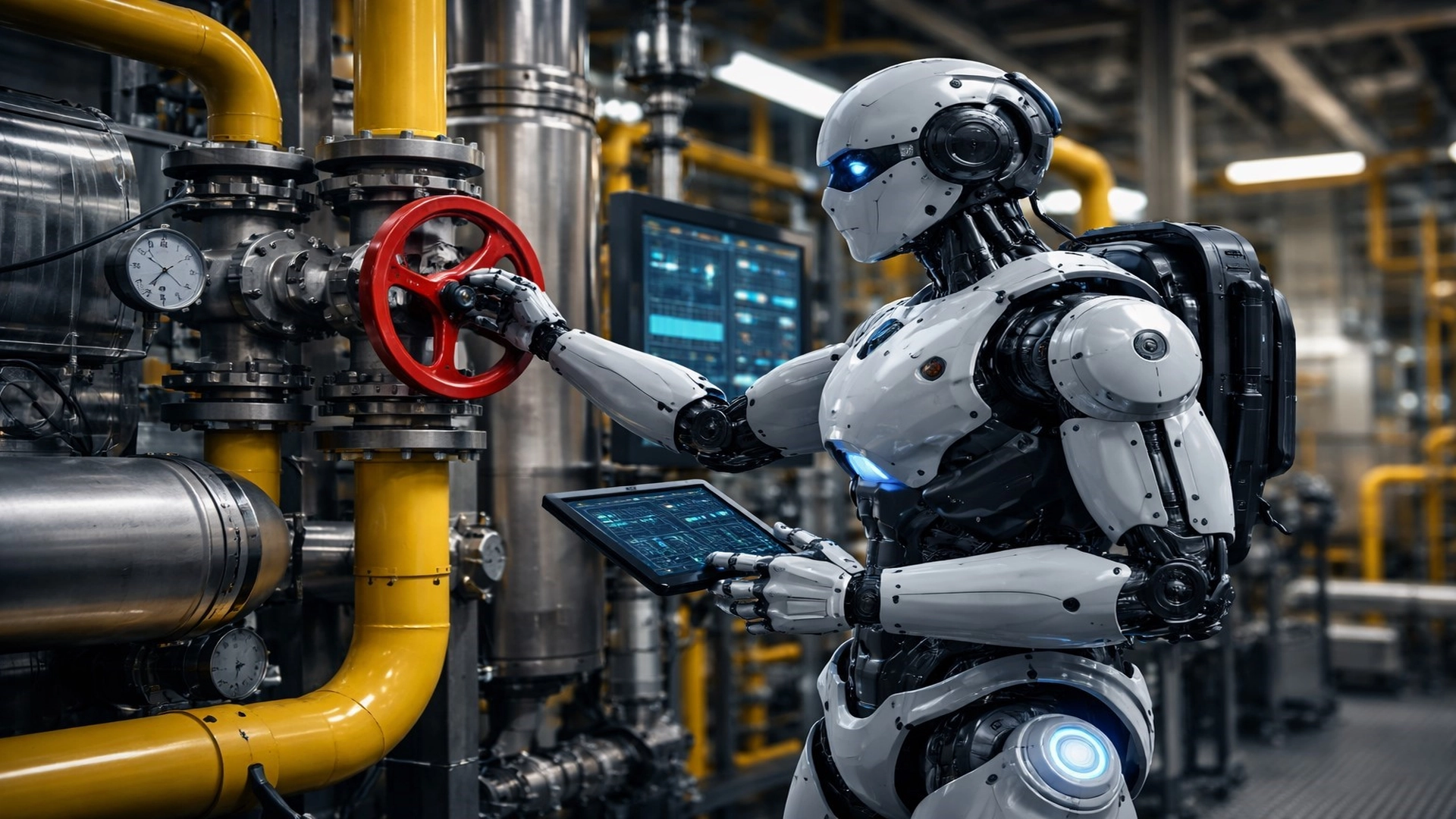

The industrial humanoid robot is a concept that has evolved from experimental environments toward applications with real potential in the energy and industrial sectors. Advancements in advanced robotics, torque and dynamic control, and perception systems have enabled the development of equipment capable of operating in unstructured environments and expanding the reach of industrial automation.

In this context, the industry faces persistent safety, access, and maintenance problems for which traditional solutions are limited. It is here where technology applied to the industry begins to position humanoid robotics as a technical alternative to solve real operational limitations.

The humanoid robot enters the industry

For decades, industrial automation has been dominated by specialized robots designed for repetitive tasks and highly controlled environments. These systems have demonstrated efficiency and reliability, but they present limitations when they must operate in infrastructures designed for humans, where there are stairs, catwalks, valves, doors, and unstructured spaces.

The industrial humanoid robot emerges as a response to this gap.

Its morphology does not respond to aesthetic criteria, but rather functional ones: it allows for interaction with existing facilities without structural redesigns. This approach reduces implementation barriers and expands the reach of cutting-edge robotics in real operations.

What defines an industrial humanoid robot?

Unlike traditional industrial robots, the industrial humanoid robot is designed to adapt to variable environments. While conventional systems excel in repetitive precision, humanoids allow for complex mobility, interaction with manual tools, and movement in spaces designed for people.

This capability expands the reach of automation in the industry without replacing existing solutions, acting as a complement in tasks where the rigidity of traditional systems represents a limitation.

The challenge: Critical problems in modern industry

Operators in the energy and industrial sectors face challenges that recur regardless of the type of facility: refineries, chemical plants, power stations, or industrial complexes share structural problems that impact safety, costs, and operational reliability.

Human exposure to risk environments

Inspections at heights, hot zones, explosive atmospheres, radiation, confined spaces, and degraded structures continue to require direct human intervention. Despite advances in procedures and protective equipment, personnel exposure remains one of the main operational and regulatory risks.

Traditional automation fails to cover these scenarios due to physical restrictions, lack of flexibility, and high adaptation costs.

Infrastructure designed for humans

The majority of existing industrial facilities were designed for human operation: stairs, catwalks, manual valves, panels, tools, and complex access points. Automating these environments without structural redesign implies high costs and long downtimes. This condition limits the implementation of conventional industrial robots and leaves large areas outside the reach of classic automation.

Maintenance costs and times

Maintenance tasks require planning, safe access, and specialized human resources. The installation of scaffolding, platforms, or temporary systems increases intervention times and affects operational continuity. This is where one of the greatest friction points between productivity, safety, and operational costs is concentrated.

The solution: The humanoid robot as a technical response

The humanoid robot emerges as a direct response to these problems, not as a substitute for existing automation, but as a complement designed to operate where other systems cannot.

Functional, not aesthetic morphology

The humanoid form allows the robot to move through environments designed for people without the need to modify the infrastructure. Stairs, narrow hallways, and irregular surfaces cease to be technical barriers. This approach reduces implementation costs and accelerates the adoption of cutting-edge robotics in existing facilities.

Torque and dynamic control in the field

The generation of high, controlled torque allows the humanoid robot to execute demanding physical tasks: opening industrial valves, manipulating loads, stabilizing itself after impacts, and operating tools. Torque and dynamic control are key to guaranteeing stability and safety in real environments, where conditions change constantly.

Control and perception architecture

Real-time processing

Unlike robots programmed with fixed trajectories, the industrial humanoid robot must interpret its environment and take decisions in real time. This requires hybrid processing architectures capable of executing control, perception, and planning simultaneously. This capability turns the robot into an active system within the applied technology ecosystem.

Sensors for complex environments

Environmental perception is achieved through the integration of sensors such as IMUs, stereo vision systems, and LiDAR. These devices allow the humanoid robot to maintain stability, identify obstacles, and move safely in complex spaces. Sensor fusion is a fundamental component of next-generation robotics oriented toward industrial environments.

Applications where the problem is greatest

Inspection in critical areas

The humanoid robotic system can execute periodic inspections in high-risk zones, significantly reducing personnel exposure and improving the early detection of damage mechanisms. This approach directly impacts operational reliability and industrial safety indicators.

An example of an application is ultrasonic thickness measurement in a refinery with the plant in service, specifically in pipes carrying hydrocarbons at high temperatures, exceeding 300°C, where human access is limited and thermal risks are high.

Maintenance at heights and access

By operating on stairs and catwalks, the robot eliminates the need for temporary infrastructure, reducing downtime and associated costs. This application attacks one of the energy sector’s greatest operational problems.

Flexible internal logistics

Next-generation robotics applied to internal logistics allows for the transport of tools and equipment in existing facilities without redesign, improving operational efficiency through adaptable automation.

Although humanoid robotics is still in a selective adoption phase, there are advanced robotic solutions currently executing traditionally human tasks in demanding industrial environments, providing tangible improvements in safety, access, and operational efficiency. Below is a table with examples of the application of this next-generation technology and innovation.

Examples of robotics and automation in industry today

| Company / System | Sector / Subsector | Activities Performed (Formerly Human) | Operational Value Provided | Source |

| PHYBOT M1 | Industry / Adv. Humanoid | Load manipulation, dynamic movement, physical tasks. | Demonstrates high torque, dynamic control, and advanced perception. | Inspenet – PHYBOT M1 challenges gravity |

| Taurob Inspector | Oil & Gas / Refining | Remote visual inspection and data capture in zoned areas. | Reduces human exposure and allows live-plant inspections. | Taurob GmbH – Industrial Inspection Robots |

| ANYmal (ANYbotics) | Oil & Gas / Petrochem | Autonomous plant inspection and instrument reading. | Increases inspection frequency and improves reliability. | ANYbotics – Industrial Inspection Solutions |

| Spot (Boston Dynamics) | Oil & Gas / Refining | Remote inspection, thermal monitoring in difficult areas. | Improves industrial safety and reduces manual inspection times. | Boston Dynamics – Industrial Inspection |

| Digit (Agility Robotics) | Manufacturing / Logistics | Internal material transport and support for repetitive tasks. | Decreases the physical load on personnel in human spaces. | Agility Robotics – Digit for Logistics |

| Apollo (Apptronik) | Mfg. / Heavy Industry | Component manipulation and physical support for operators. | Reduces human effort in physically demanding tasks. | Apptronik – Apollo Humanoid Robot |

These examples show that the industry is already incorporating robotic solutions capable of executing human tasks in complex environments, even before a massive adoption of full humanoid robots. Based on this technological and operational foundation, the most advanced use cases for humanoid robotics are being built.

Success case: Humanoid robotics in industrial operation

In a nuclear facility operated by Orano, inspections in restricted areas involved high operational risks. The need to reduce human exposure led to the evaluation of advanced robotics solutions capable of being integrated without modifying existing infrastructure.

In collaboration with Capgemini, the humanoid robot Hoxo was deployed, configured to move autonomously, perform inspections, and transmit data in real time. Its design allowed for the application of industry-applied technology in a critical environment.

The implementation of the industrial humanoid robot significantly reduced personnel exposure to risk zones, improved inspection frequency, and validated the viability of humanoid-based automation.

As a complement to the application case described, the interview conducted by Inspenet TV with representatives of Re-Gen Robotics provides a direct vision from a company that currently operates robotic solutions in the oil & gas and refining subsector. In this material, the real challenges associated with crude oil tank cleaning are addressed, and how robotics allows for the elimination of critical risks for human personnel:

- Total elimination of human entry into confined spaces: Reduces or eliminates risks associated with explosive atmospheres and hazardous waste.

- Visual documentation and improved maintenance planning: Visual evidence for audits, subsequent analysis, and decision-making in asset maintenance programs.

- Greater operational continuity in extreme conditions: Reduces downtime and improves the overall efficiency of the intervention.

Challenges for its adoption

Despite its potential, the adoption of the industrial humanoid robot presents technical and operational challenges that must be rigorously evaluated before implementation in production environments. One of the main challenges is long-term mechanical robustness. Unlike controlled environments, industrial facilities expose equipment to vibrations, dust, humidity, thermal variations, and repetitive mechanical stresses that can accelerate the wear of actuators, transmissions, and sealing systems. Guaranteeing reliability under these conditions requires reinforced designs and predictive maintenance strategies.

Energy autonomy represents another critical factor. Intensive physical tasks, such as load manipulation or prolonged movements, demand high energy consumption. In real industrial applications, the limited capacity of batteries can restrict continuous operating time, forcing the planning of recharge cycles or exchange stations. This directly impacts the scheduling of inspections, maintenance, and logistical support, especially in large plants.

Integration with existing systems also poses significant challenges. The industrial humanoid robot must interoperate with control platforms, asset management systems, IIoT networks, and established safety protocols. The lack of unified standards can complicate integration, requiring custom developments to ensure compatibility and cybersecurity.

Finally, the return on investment analysis is decisive. Not all tasks justify the use of cutting-edge robotics. Its adoption should focus on activities where the reduction of human risk, improvement of operational continuity, or decrease in downtime compensates for the initial investment. In this sense, responsible implementation implies selecting well-defined use cases where industrial automation provides measurable and sustainable value.

Evolution of physical automation

Automation is in a process of transition toward hybrid models in which humans and robots collaborate in a complementary manner. In this new paradigm, the industrial humanoid robot does not replace existing automated systems, but rather expands their reach by operating in environments where the rigidity of classic automation is inefficient or unfeasible.

In the short and medium term, these robots will act as mobile intervention platforms for complex tasks, such as inspections at height, access to confined areas, manipulation of heavy components, and support for corrective maintenance. Their ability to adapt to human-designed infrastructure allows for the integration of applied technology in the industry without significant structural modifications.

Future evolution contemplates deeper integration with IIoT ecosystems and predictive systems. By operating as mobile nodes, humanoid robots will be able to collect field data, vibrations, temperatures, images, environmental conditions, and feed predictive maintenance models and digital twins. This approach will allow for the anticipation of failures, optimization of interventions, and improvement of operational decision-making.

In this context, next-generation robotics will consolidate itself as an enabler of flexible physical automation, capable of adapting to the variability of the industrial environment. For operators in the energy and industrial sectors, this evolution represents a strategic opportunity to address historical problems of safety, access, and efficiency through applied and scalable technological solutions.

Conclusions

The industrial humanoid robot represents a tangible evolution of advanced robotics applied to energy and industrial environments. Its ability to integrate into existing infrastructure, operate in unstructured spaces, and reduce human exposure to risk conditions positions it as a strategic tool within industrial automation, provided its adoption is based on solid technical criteria and well-defined use cases.

Beyond the technological impact, its real value lies in the resolution of historical operational problems related to safety, access, and efficiency. When implemented as part of an applied technology and innovation strategy for the industry, the industrial humanoid robot can complement traditional automated systems, provide operational flexibility, and enable new approaches to maintenance, inspection, and operational continuity in complex facilities.

Content developed by Inspenet, the digital platform that connects problems, solutions, and industrial knowledge to keep the world producing!

References

- International Federation of Robotics. (2023). World robotics report: Service and industrial robots. https://ifr.org/worldrobotics

- Boston Dynamics. (2022). Robotics in industrial inspection and maintenance. https://www.bostondynamics.com/solutions

- Capgemini Research Institute. (2023). Intelligent automation and the rise of advanced robotics in industry. https://www.capgemini.com/research

- World Economic Forum. (2023). Humanoid robots and the future of industrial automation. https://www.weforum.org

- Capgemini & Orano. (2025). Capgemini and Orano deploy the first intelligent humanoid robot in the nuclear sector. Official press release. https://www.capgemini.com/news/press-releases/capgemini-and-orano-deploy-the-first-intelligent-humanoid-robot-in-the-nuclear-sector/

- Inspenet TV. (2025). Robots for crude oil tank cleaning | Re-Gen Robotics [Video]. https://inspenet.com/video-tv/robots-para-limpieza-de-tanques-de-crudo/

Frequently Asked Questions (FAQs)

What is an industrial humanoid robot?

A humanoid robot is a robotic system designed to operate in industrial environments using a morphology compatible with infrastructures intended for humans. Unlike conventional industrial robots, it can move across stairs, catwalks, and unstructured areas, interact with existing equipment, and execute complex physical tasks without relevant structural modifications.

What industrial problems does humanoid robotics solve?

Advanced robotics applied to humanoid systems allows for addressing critical problems such as personnel exposure to risk zones, limited access to confined or elevated areas, and high costs associated with inspections and maintenance in energy and industrial facilities.

Why are torque and dynamic control key?

Torque and dynamic control determine the robot’s ability to manipulate loads, open industrial valves, maintain balance, and absorb impacts in real operating conditions, guaranteeing stability, safety, and reliability in demanding industrial environments.

Where does a humanoid robot provide the greatest value?

An industrial humanoid robot provides the most value in high-risk inspections, maintenance at heights, work in confined spaces, and flexible internal logistics, where traditional industrial automation presents technical or economic limitations.

What are the challenges for its adoption?

The main challenges include mechanical robustness, energy autonomy, integration with existing industrial systems, and return on investment analysis. The adoption of cutting-edge robotics requires well-defined use cases and clear technical criteria.

How is it integrated into current industrial systems?

The humanoid robot can be integrated with IIoT platforms, asset management systems, and predictive maintenance solutions, acting as a mobile node of industry-applied technology without altering existing architectures.

Do humanoid robots replace personnel?

No. Automation is evolving toward collaborative models where the humanoid robot complements human personnel by taking on high-risk or high-physical-load tasks, keeping the operator in supervision and control functions.

Which sectors benefit most from this technology?

The energy, oil & gas, nuclear, petrochemical, manufacturing, and heavy infrastructure sectors present high potential for adopting industry-applied technology based on humanoid robotics.

Is humanoid robotics already a mature technology?

Humanoid robotics is in a transition toward selective adoption. Real cases exist that validate its use, but its implementation must focus on applications where the operational value is clear, measurable, and sustainable.