Table of Contents

- What is a Subsea Hot Tap?

- What is the purpose of a Hot Tap?

- Technical challenges of Hot Tapping in Subsea pipelines

- Offshore environmental and operational conditions

- Mechanical integrity and risk control

- Codes and standards applicable to Subsea Hot Tapping

- Key technologies associated with Subsea Hot Tapping

- Advantages of Subsea Hot Tapping in offshore systems

- Subsea Hot Tapping and predictive maintenance

- Experience and technical capabilities in Offshore Hot Tapping

- Typical application cases of Subsea Hot Tapping

- Conclusions

- References

- Frequently Asked Questions (FAQs)

- Under what conditions is a subsea hot tap NOT recommended?

- What integrity assessments must be performed before a subsea hot tap?

- What is the difference between subsea hot tapping with welding and mechanical solutions?

- How is environmental risk managed during a subsea hot tap?

- Can subsea hot tapping be integrated into a predictive maintenance strategy?

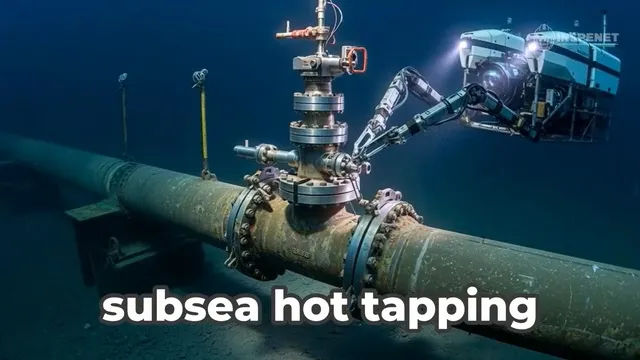

Subsea hot tapping has become one of the most critical and sophisticated solutions for ensuring operational continuity in offshore operations. In an environment where production shutdowns entail significant economic impacts, elevated operational risks, and complex logistical challenges, the ability to intervene on in-service subsea pipelines, without depressurization or flow interruption, represents a strategic advantage for operators and asset owners.

Unlike conventional interventions, these operations are performed under extreme conditions, where hydrostatic pressure, limited access, and the need for absolute risk control turn each execution into a true engineering challenge. When properly applied, subsea hot tapping prevents unplanned shutdowns and reduces risk exposure, optimizes maintenance schedules, and extends the service life of critical infrastructure.

Within this context, subsea hot tapping emerges as a key enabling technology for modern offshore operations, integrating advanced engineering, mechanical integrity principles, and strict safety standards to intervene in complex systems without compromising production or the marine environment.

What is a Subsea Hot Tap?

A subsea hot tap is a hot intervention technique that enables connections, branches, or modifications on pressurized subsea pipelines while keeping the system in continuous operation. As with conventional hot tapping, the process involves installing a specialized fitting (such as a split tee), sealing it onto the existing pipeline, and drilling through the pipe wall in a controlled manner. However, in a subsea environment, this operation reaches a significantly higher level of complexity.

To understand the operating principle of hot tapping on an in-service pipeline, the following video clearly illustrates how a connection is made to a pressurized pipeline without interrupting flow, including controlled drilling and temporary isolation of the intervened segment. Source: Rangeline Tapping Services.

How Pipeline Line Stop services are performed.

The primary difference between topside hot tapping and its subsea application lies in the hyperbaric conditions under which the intervention is executed. External pressure, permanent water presence, limited visibility, and reliance on specialized divers or remotely operated vehicles (ROVs) require the development of tailored procedures, incorporating redundant sealing systems and stringent integrity controls.

In this context, subsea hot tapping enables intervention without interrupting flow, which is critical for offshore production, injection, and transportation lines. Successful execution depends on rigorous pre-assessment of pipeline condition, accurate control of remaining wall thickness, and material compatibility, ensuring the operation is carried out safely and in a controlled manner within hot tapping systems applied to underwater pipelines.

What is the purpose of a Hot Tap?

The primary purpose of a hot tap is to enable safe and controlled intervention on pressurized systems without interrupting operations. In offshore and subsea environments, where production shutdowns carry significant economic, operational, and environmental consequences, hot tapping provides a strategic alternative to conventional isolation and repair methods.

One of its core objectives is operational continuity. By allowing modifications to be performed while the system remains in service, a hot tap eliminates the need for depressurization, purging, or line evacuation, procedures that are often complex, costly, or impractical in offshore facilities.

Additionally, hot tapping enables system modifications, branch connections, and tie-ins to existing infrastructure. These interventions may include installing bypasses, adding monitoring points, or connecting new lines to active systems, all while maintaining flow stability and process integrity.

From an asset management perspective, hot tapping also plays a fundamental role in integrity management without shutdown, allowing infrastructure to adapt to new operational requirements without compromising safety criteria or the service life of offshore assets.

Technical challenges of Hot Tapping in Subsea pipelines

The execution of this type of intervention represents one of the most demanding technical challenges in offshore operations, due to the combination of extreme environmental conditions, operational constraints, and strict safety requirements. Unlike topside interventions, every stage of the process must account for external variables that cannot be directly controlled, requiring detailed planning and the application of conservative engineering criteria to preserve system integrity.

Offshore environmental and operational conditions

Subsea pipelines operate in a dynamic and hostile environment, where hydrostatic pressure increases proportionally with depth and imposes constant loads on sealing systems, hot tap fittings, and drilling equipment. This external pressure not only influences the design of subsea fittings but also dictates installation procedures and limits the operational windows available for the intervention.

In addition, marine currents can generate additional stresses on the pipeline and on temporary equipment installed during the hot tap operation. These currents affect the stability of clamping systems, complicate precise component alignment, and significantly increase operational complexity for divers or remotely operated vehicles (ROVs).

Limited visibility is another critical factor. Sediments, turbidity, and reduced lighting conditions hinder direct visual inspection, requiring the use of measurement instruments, subsea cameras, and high-precision positioning systems. In this context, safe execution of the hot tap relies heavily on the quality of procedures and the experience of the technical team.

Finally, thermal control becomes particularly relevant in active lines transporting fluids at elevated or variable temperatures. The interaction between process temperature, the marine environment, and system materials can generate thermal gradients that influence mechanical stresses and material behavior during hot drilling operations.

Mechanical integrity and risk control

Beyond environmental factors, the intervention must be approached from a rigorous mechanical integrity perspective, where system safety under operating conditions is the dominant criterion. Controlling stresses induced by fitting installation, drilling, and subsequent operation is essential to prevent stress concentrations that could compromise pipeline strength.

Material compatibility between the existing pipeline, the hot tap fitting, and sealing elements is another critical consideration. Differences in mechanical properties, thermal expansion coefficients, or corrosion resistance may lead to undesirable behavior under subsea conditions, particularly in systems subjected to thermal cycling and variable loads.

Likewise, the management of existing pipeline defects, such as external corrosion, wall-thickness loss, mechanical damage, or metallurgical discontinuities, must be evaluated before any intervention, where in-service visual inspection provides real-world evidence to support integrity assessments in accordance with API 570. In this regard, standards such as API 570 provide guidance for inspection and evaluation of piping systems, while API 581 enable integration of these findings into a quantitative Risk-Based Inspection (RBI) assessment. This combination of advanced inspection and risk-based evaluation is fundamental to determining hot tap feasibility and defining appropriate mitigation measures.

Overall, effective mechanical integrity management and risk control make subsea hot tapping a highly specialized intervention, where engineering, inspection, and operational expertise must act in a coordinated manner to ensure safe and reliable execution in offshore operations.

Codes and standards applicable to Subsea Hot Tapping

The execution of a subsea hot tap requires a robust regulatory framework to manage the inherent risks associated with hot work on pressurized systems under offshore conditions and limited access. While there is no single standard dedicated exclusively to subsea hot tapping, industry practice relies on widely recognized codes that, when properly interpreted and adapted, provide a solid foundation for planning, execution, and control of such operations.

API 2201 and its application to Hot Tapping

API 2201 – Safe Hot Tapping Practices in the Petroleum & Petrochemical Industries is the primary reference document for any hot tapping operation, including those performed in subsea environments. Its core objective is to ensure that hot tapping activities are conducted safely, controlling risks associated with drilling into in-service equipment and pipelines.

One of the fundamental pillars of API 2201 is pre-job risk assessment. Before authorizing a hot tap, the standard requires evaluation of critical variables such as operating pressure and temperature, fluid characteristics, remaining wall thickness, metallurgical condition of the material, and the presence of active damage mechanisms. For subsea hot tapping, this assessment must be expanded to include offshore-specific factors such as hydrostatic pressure, marine currents, and access limitations.

API 2201 also defines technical procedures for fitting installation, sealing, controlled drilling, and coupon management, emphasizing detailed planning, personnel qualification, and equipment verification. In subsea applications, these procedures are typically adapted through specialized fitting designs, redundant sealing systems, and methodologies compatible with diver or ROV execution, while maintaining the original intent of the standard: preventing leaks, ignition, or loss of containment.

However, it is important to recognize the limitations of API 2201 in offshore applications. As the standard was primarily developed for topside facilities, its application to subsea hot tapping requires additional engineering judgment, complementary analyses, and, in many cases, integration with offshore specific standards and hyperbaric risk assessments.

Integration with API 570 and API 581

For a subsea hot tap to be technically viable and safe, compliance with API 2201 alone is not sufficient.

The process must be integrated within a broader framework of inspection, evaluation, and risk management, in which API 570 and API 581 play a key role.

API 570, Piping Inspection Code, provides the criteria for the pre-intervention inspection of piping systems, enabling assessment of the actual condition of the pipeline prior to any hot tap operation. In subsea environments, this inspection is typically supported by advanced techniques such as ultrasonic testing, pulsed eddy current inspection, or computed radiography, with the objective of confirming remaining wall thickness, identifying active corrosion, or detecting discontinuities that could compromise integrity during the hot tap.

API 581, Risk-Based Inspection (RBI), allows inspection results to be integrated into a quantitative RBI assessment, evaluating both the probability and consequences of failure associated with the intervention. This approach is particularly relevant for subsea hot tapping, where the impact of an unplanned failure can be severe from environmental, operational, and reputational perspectives. RBI supports informed decision-making, defining whether hot tapping is acceptable from a risk standpoint and identifying the mitigation measures that must be implemented.

Finally, the combined application of API 570 and API 581 enables a more accurate remaining life assessment, ensuring that the intervened pipeline not only withstands the hot tapping operation, but also maintains its integrity over time. This regulatory integration positions subsea hot tapping as an intervention aligned with modern mechanical integrity principles, where safety and asset reliability prevail over reactive or short-term solutions.

Key technologies associated with Subsea Hot Tapping

The feasibility and safety of a subsea hot tap depend largely on the use of specialized technologies that enable the intervention to be executed under hyperbaric conditions while maintaining quality control and system integrity before, during, and after the operation. Among these technologies, hyperbaric welding and advanced non-destructive inspection techniques play a decisive role.

Hyperbaric welding and quality control

Hyperbaric welding is one of the most critical technologies associated with this type of intervention, as it enables fittings, branch connections, or tapping systems to be directly attached to in-service subsea pipelines. Depending on water depth, operating conditions, and quality requirements, this welding can be performed using two main approaches: wet welding and dry welding.

Wet welding is carried out directly in the marine environment, with the electric arc exposed to water. Its primary advantages are rapid execution and reduced logistical costs; however, it presents greater metallurgical challenges, including higher cooling rates, increased risk of hydrogen embrittlement, and reduced control over weld microstructure.

Dry welding, on the other hand, is performed inside hyperbaric chambers that isolate the work area from the surrounding water. This method provides greater process control, improved mechanical properties, and superior joint quality, making it the preferred option for critical subsea hot tap applications, albeit with higher technical requirements and associated costs.

Regardless of the method used, metallurgical risks must be carefully assessed. Proper selection of welding procedures, welder qualification, thermal parameter control, and material compatibility are essential to prevent defects such as cracking, lack of fusion, or degradation of mechanical properties. Joint integrity assurance relies not only on correct welding execution but also on post weld validation through advanced inspection, ensuring that the intervention does not compromise the integrity of the in-service system.

Advanced inspection before and after the Hot Tap

Advanced inspection is an inseparable component of subsea hot tapping, as it ensures pipeline integrity without removing the system from service, both during pre-intervention assessment and post-intervention verification. Before executing the hot tap, these techniques confirm that the pipeline meets minimum requirements for wall thickness, metallurgical condition, and absence of critical defects, often supported by eddy current based inspection methods for localized corrosion and wall loss screening.

Pulsed Eddy Current (PEC) inspection is particularly useful in subsea environments and in coated or insulated lines, as it enables wall-thickness loss evaluation through coatings without requiring direct access to the metal surface, as described in the article Pulsed Eddy Current (PEC) for CUI in Elevated and Insulated Pipelines. In addition, remote visual inspection techniques such as borescopy applied in NDT provide internal visual evidence in inaccessible areas, complementing defect characterization prior to installing the hot tap fitting. This capability is key to identifying weakened areas before the fitting is installed.

Phased Array Ultrasonic Testing (PAUT) and Time of Flight Diffraction (TOFD) provide detailed characterization of internal discontinuities and welds, allowing precise detection of cracks, lack of fusion, or volumetric defects. These techniques are widely used to validate the quality of hyperbaric welds and verify the integrity of critical joints associated with the hot tap.

As a complementary method, computed radiography offers advanced volumetric evaluation, particularly valuable in complex geometries or when additional confirmation of internal material condition is required. Its integration with other NDT techniques enhances overall inspection reliability.

Together, these technologies enable subsea hot tapping to be executed under a condition-based mechanical integrity approach, reducing technical uncertainty and ensuring that the intervention is performed safely, in a controlled manner, and in alignment with the demands of modern offshore operations.

Advantages of Subsea Hot Tapping in offshore systems

Subsea hot tapping has become a strategic solution within offshore operations, not only due to its technical capability but also because of its direct impact on operational continuity, cost control, and risk management. Its application goes beyond a single intervention, positioning it as a high-value tool for optimizing subsea assets.

Operational continuity and cost reduction

One of the primary advantages of subsea hot tapping is its ability to avoid shutdowns in critical systems. In offshore environments, production stoppages entail high costs associated with throughput losses, process reconfiguration, marine logistics, and, in numerous instances, additional risks during restart operations. Subsea hot tapping enables connections, branches, or modifications to be performed without interrupting flow, maintaining stable and continuous operation.

By minimizing production losses, this technique delivers an immediate positive economic impact. Each day of uninterrupted operation represents a significant reduction in indirect costs, particularly in mature fields or installations with tight operating margins. Furthermore, by avoiding invasive interventions, personnel and equipment exposure to hazardous conditions is significantly reduced.

From an HSE perspective, subsea hot tapping also contributes to risk reduction. By limiting complex isolation, depressurization, or purging activities, the likelihood of uncontrolled releases, environmental incidents, and surface hot-work safety events is reduced.

Operational flexibility and service life extension

Beyond operational continuity, subsea hot tapping provides operational flexibility that is critical in dynamic offshore scenarios. It enables safe modifications to existing systems, such as adding new lines, bypasses, monitoring points, or temporary connections, without compromising pipeline integrity or process stability.

This adaptability is particularly valuable when assets must respond to new operational scenarios, including changes in production regimes, integration of additional infrastructure, or extension of field life cycles. Rather than replacing entire pipelines or performing major interventions, subsea hot tapping enables engineering solutions that extend the service life of subsea pipelines, optimizing existing investments while maintaining safety and reliability.

Subsea Hot Tapping and predictive maintenance

The evolution of this technique is not limited to the mechanical execution of the intervention itself. Its integration with predictive maintenance strategies has opened new possibilities for intelligent subsea asset management, where anticipation and data-driven analysis play a central role.

Remote monitoring and embedded sensors

The use of remote monitoring and embedded sensors allows the value of a hot tap to extend well beyond the moment of intervention. Through connections established via hot tapping, it is possible to install humidity sensors, structural monitoring devices, and data acquisition systems capable of operating continuously in subsea environments.

These sensors provide real-time information on critical variables such as environmental conditions, material integrity, and operational changes, without the need for frequent physical intervention. The digital integration of this data into monitoring platforms enables early detection of degradation precursors, facilitating proactive asset management and aligning subsea hot tapping with the principles of modern predictive maintenance.

Condition and data based management

When data collected through sensors and monitoring systems is integrated with dynamic RBI models, the management approach evolves toward condition-based management. This model allows continuous updating of risk assessments based on actual system behavior, rather than relying solely on fixed inspection intervals or conservative assumptions.

The availability of real-time data supports timely technical decision-making, optimizing inspection planning, interventions, and maintenance resource allocation. From an Asset Integrity Management perspective, this integration transforms subsea hot tapping into a strategic tool, not only for maintaining operations, but for enhancing the reliability, safety, and performance of offshore assets throughout their service life.

The following video shows the key concepts, critical applications, and impact of subsea hot tapping on predictive maintenance and data based management.

Experience and technical capabilities in Offshore Hot Tapping

The execution of offshore hot tapping operations, particularly in subsea environments, requires far more than mastery of a specific technique. It demands a solid combination of applied engineering, deep understanding of operational risks, and the ability to integrate standards, technologies, and critical decision-making in highly complex scenarios.

BUZCA S.A.: Applied engineering for complex operations

Within this context, BUZCA S.A. represents an example of how specialized engineering translates into viable solutions for demanding industrial operations in Latin America. With a well-established track record in the development of engineering projects for the energy and industrial sectors, the company has built technical capabilities focused on solving complex challenges where operational continuity and safety are decisive factors.

BUZCA S.A.’s experience in projects involving pressurized systems, critical infrastructure, and severe operating environments enables the company to approach offshore hot tapping interventions from an integrated perspective. This includes prior structural analysis, material compatibility, operational risk assessment, and the alignment of each stage of the process with integrity engineering expertise and recognized industry standards.

A distinctive element of this approach is the ability to execute solutions under strict regulatory frameworks, integrating safe practices, controlled procedures, and mechanical integrity criteria that reduce technical uncertainty. In operations where errors may translate into significant operational, environmental, or reputational impacts, engineering discipline and adherence to standards such as API 2201, API 570, and RBI methodologies become essential.

Beyond technical execution, the true value of these capabilities lies in their contribution to operational continuity. Applied engineering enables the design of interventions that avoid unnecessary shutdowns, optimize resources, and extend the service life of offshore assets—while consistently prioritizing personnel safety, marine environment protection, and system reliability.

In this sense, BUZCA S.A.’s experience demonstrates how well-applied engineering is not limited to solving isolated problems, but becomes a strategic enabler for the sustainable management of complex offshore and subsea infrastructure.

Typical application cases of Subsea Hot Tapping

Subsea hot tapping delivers its greatest value in scenarios where direct intervention on critical infrastructure must be performed without compromising operations or system integrity. Its application is not limited to emergencies; rather, it forms part of planned offshore asset management strategies.

In subsea production lines, hot tapping enables additional connections, instrumentation, or system modifications to be carried out without interrupting hydrocarbon flow. This capability is particularly relevant in mature fields or installations where operational continuity is essential to the economic viability of the project.

Another common application involves subsea branch connections, where new tie-ins are required to manifolds, auxiliary systems, or future field expansions. Hot tapping facilitates these integrations by minimizing the need for invasive interventions, reducing execution time, and limiting risk exposure.

Additionally, subsea hot tapping is an effective solution for repairs without service interruption, allowing sections to be isolated, reinforcements to be installed, or controlled corrections to be performed on pipelines exhibiting localized degradation. In these scenarios, the combination of advanced inspection, integrity assessment, and standardized procedures is critical to ensuring safe and reliable outcomes.

Conclusions

This intervention has become a strategic tool within modern offshore operations, offering a technical solution that balances operational continuity, safety, and risk control in highly demanding environments. Its application goes beyond a single technique; it represents an integrated approach to intervening on critical infrastructure without resorting to shutdowns that impact production, costs, and operational planning.

The effectiveness of subsea hot tapping depends on the coherent integration of specialized engineering, advanced inspection, and regulatory compliance. Standards such as API 2201, together with their alignment with API 570 and API 581, enable risk-based decision-making, remaining life evaluation, and the execution of interventions under sound technical criteria.

As the offshore industry moves toward more efficient and resilient operating models, subsea hot tapping positions itself as a key enabler of intelligent asset management. Its combination with monitoring technologies, predictive maintenance, and data analytics reinforces the transition toward safer, more adaptable, and sustainable operations capable of meeting present and future challenges in the marine environment.

References

- American Petroleum Institute. (2016). API RP 2201: Safe hot tapping practices in the petroleum and petrochemical industries (4th ed.). API Publishing Services.

- American Petroleum Institute. (2016). API 570: Piping inspection code: In-service inspection, rating, repair, and alteration of piping systems (4th ed.). API Publishing Services.

- American Petroleum Institute. (2016). API RP 581: Risk-based inspection methodology (3rd ed.). API Publishing Services.

- American Petroleum Institute. (2018). API RP 2A-WSD: Planning, designing, and constructing fixed offshore platforms—Working stress design. API Publishing Services.

Frequently Asked Questions (FAQs)

Under what conditions is a subsea hot tap NOT recommended?

Subsea hot tapping should not be performed when asset or environmental conditions compromise the safety or reliability of the intervention. Key limiting factors include severe corrosion that has significantly reduced wall thickness, insufficient remaining thickness to withstand thermal and mechanical stresses during drilling, or the presence of materials incompatible with the intended welding or connection procedures.

Additionally, scenarios involving unacceptable environmental risks—such as high ecological sensitivity, extreme marine currents, or limited capability to implement effective containment measures—may rule out subsea hot tapping, favoring more conservative alternatives from an HSE perspective.

What integrity assessments must be performed before a subsea hot tap?

Prior to any subsea hot tapping operation, it is essential to conduct a comprehensive mechanical integrity assessment. This includes advanced inspection using Phased Array Ultrasonic Testing (PAUT), TOFD, and Pulsed Eddy Current (PEC) techniques to characterize wall-thickness loss, existing defects, and local metallurgical conditions.

These inspections must be complemented by metallurgical evaluation, material compatibility analysis, and a stress analysis that considers internal pressure, external loads, and hyperbaric conditions. Finally, the process should be integrated into a quantitative Risk-Based Inspection (RBI) assessment in accordance with API 581, ensuring that overall system risk remains within acceptable limits.

What is the difference between subsea hot tapping with welding and mechanical solutions?

Subsea hot tapping can be executed using hyperbaric welding or through mechanical solutions, such as specialized connectors or clamps. Welding provides a permanent and structurally continuous joint, but involves greater technical challenges, strict metallurgical control, and longer execution times.

Mechanical solutions, on the other hand, often reduce intervention time and operational complexity, although they may present limitations in pressure, temperature, or service life. The selection between these approaches depends on acceptable risk levels, asset condition, reliability requirements, and the operational horizon of the system.

How is environmental risk managed during a subsea hot tap?

Environmental risk management is a critical component of hot tapping subsea. This involves implementing strict leak controls, redundant sealing systems, and containment barriers designed to minimize any unintended release into the marine environment.

In addition, continuous monitoring is employed throughout the operation, along with specific response plans that address contingency scenarios. This combination of preventive engineering, real-time supervision, and response protocols significantly reduces potential environmental impact.

Can subsea hot tapping be integrated into a predictive maintenance strategy?

Yes. Subsea hot tapping can be integrated into an advanced predictive maintenance strategy, particularly when combined with embedded sensors, remote monitoring systems, and data analytics platforms.

These systems support condition-based management, feeding real-time asset data into mechanical integrity models and dynamic RBI frameworks. In this way, hot tapping addresses an immediate operational need and becomes a key element within a comprehensive Asset Integrity Management approach focused on long-term reliability and resilience.