Table of Contents

- Corrosion mechanisms in exposed environments

- Passive corrosion control strategies

- Industrial case studies: Effective field protection

- Advantages of passive protection vs. active alternatives

- Conclusions

- References

- FAQs about passive corrosion protection

- What is the key difference between passive protection and cathodic protection?

- What are the benefits of passive protection in hard-to-access areas?

- How do I know if my asset requires specialized corrosion protection?

- Is surface preparation necessary before applying a passive solution?

- What type of maintenance does a well-implemented passive system require?

Whether it’s an onshore compression station, a pipeline cutting through forested land, or a coastal terminal exposed to salt-laden winds, energy infrastructure is constantly under siege from a quiet and often underestimated enemy: corrosion. This electrochemical phenomenon gradually deteriorates metals exposed to the environment or in contact with soil, compromising the structural integrity of critical assets and leading to potentially catastrophic consequences, both operationally and financially.

Among the various forms of material degradation, soil-induced and atmospheric corrosion are particularly damaging to infrastructure, especially when protection systems are absent or outdated. Factors such as persistent humidity, airborne salinity in coastal zones, or the acidity of certain soil types turn these environments into minefields for any unprotected metallic structure. Prolonged exposure, without specialized coatings or passive mitigation strategies, can result in unexpected failures, unplanned shutdowns, and multimillion-dollar losses.

Identifying corrosion risks early is key to making informed decisions that improve long-term reliability and reduce unexpected downtime. In the sections that follow, we take a closer look at how passive protection strategies can offer real-world solutions to these challenges.

Corrosion mechanisms in exposed environments

In actual field operations, corrosion rarely happens in isolation. It’s usually the product of several overlapping factors working together over time. When dealing with assets exposed to the atmosphere or buried underground, the mechanisms that trigger metal degradation are diverse and complex. Understanding them is not merely academic; it is a critical operational need for those managing assets where preserving structural integrity is non-negotiable. See this comparative analysis of how different metals respond to severe corrosive environments.

Atmospheric corrosion: The impact of oxygen and humidity

When metal surfaces are continuously exposed to oxygen and moisture in the air, they become prone to one of the most persistent types of degradation: atmospheric corrosion. In the presence of industrial pollutants, salt spray in coastal areas, or microclimates with high relative humidity, metal surfaces, particularly carbon steel, begin to form oxides that accelerate progressive damage. This type of attack becomes especially severe in structures lacking preventive maintenance or with deteriorated coating systems, posing a latent threat to platforms, tanks, and the structural integrity of metallic systems.

Underground corrosion: Soil-metal interaction

Underground environments present their own set of challenges. Corrosion in these settings arises from the ongoing chemical interaction between buried metals and the surrounding soil. Factors such as soil pH, the presence of chlorides and sulfates, and soil resistivity can accelerate degradation processes that often go unnoticed, until it’s too late.

Special attention should be paid to the soil-air interface zone, where cyclic moisture and partial exposure create even more aggressive conditions. Without proper understanding of soil properties and a well-planned protection approach, the integrity of underground assets like pipelines and pilings can be at serious risk over time.

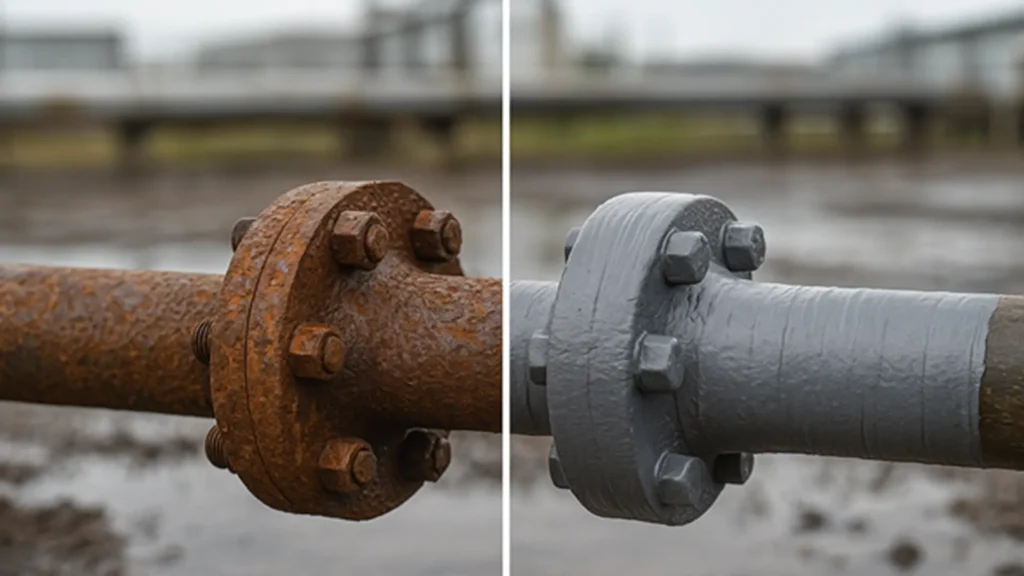

This comparison clearly illustrates the impact of applyingor not applyinga passive protection strategy. On the left, a metallic joint exposed to high humidity and wet soil conditions shows visible signs of corrosion. On the right, the same geometry, protected with an anticorrosive wrapping system, maintains its visual and functional integrity. A single technical decision can mean the difference between accelerated deterioration and preserved assets.

Passive corrosion control strategies

In harsh settings, passive protection frequently serves as the most reliable and immediate defense against corrosion. These strategies rely on creating durable physical barriers that isolate the substrate from corrosive agents, whether atmospheric or buried. For operators managing assets in remote locations or high-risk zones, passive systems offer a low-maintenance, cost-effective solution that significantly extends service life without constant monitoring.

Unlike active methods, such as cathodic protection, passive systems require minimal intervention once correctly applied. The success of these solutions, however, depends heavily on application quality, compatibility with site conditions, and long-term performance under mechanical and environmental stresses.

Importance of surface preparation

Every corrosion protection system begins with the substrate. Contaminants such as dust, oils, old coatings, or rust layers must be completely removed to ensure proper adhesion of subsequent layers, as detailed in our surface preparation article.

Depending on the environment and material, this may involve mechanical cleaning, shot blasting, or chemical conditioning. Omitting this critical step compromises the entire protective barrier, leading to premature failure, peeling, or hidden corrosion under the coating. Surface preparation is not a recommendation: it is a technical requirement to ensure long-term durability and should be considered an essential part of any predictive maintenance program.

Application of primers and putties

Primers and putties serve a dual role in passive corrosion control: they act as adhesion promoters and fillers that conform to irregular surfaces. Primers create a bonding interface between the metal and topcoat, enhancing durability and resistance to moisture ingress. Putties, often epoxy- or resin-based, are formulated to fill voids, smooth weld seams, and reinforce vulnerable geometries like flanges and bolted joints.

In harsh environments, like offshore terminals or buried pipelines in acidic soils, these base layers are critical to ensuring that the outer protection performs as intended. Specialized manufacturers have developed formulations tailored for specific applications, from high-humidity conditions to cold-applied systems that eliminate the need for heat or special curing equipment. These technologies offer reliability even in hard-to-access field conditions, making them essential tools in modern corrosion mitigation arsenals.

Coating systems and Wax-Tape Wraps

Among the most effective passive protection solutions are Wax-Tape® systems, developed by Trenton Corporation, and based on microcrystalline waxes. These hydrophobic materials form a pliable, water-resistant barrier that adheres to irregular surfaces and maintains flexibility over time. Unlike rigid coatings, wax-based wraps accommodate expansion, vibration, and thermal cycling without cracking or peeling.

These systems excel in real-world applications, particularly where ideal surface preparation isn’t possible or where weather conditions render standard coatings difficult to apply. They are widely used to protect exposed pipe joints, flanged connections, and casing transition areas highly susceptible to moisture ingress and crevice corrosion. Once applied, the wax-tape conforms tightly to the substrate and remains stable even in fluctuating temperatures or submerged conditions.

These systems are gaining traction in the oil and gas, marine, and utility sectors, where longevity, ease of application, and minimal maintenance are non-negotiable. By leveraging these advanced materials and techniques, asset managers can build a robust corrosion defense strategy tailored to real-world challenges.

Industrial case studies: Effective field protection

Ensuring asset integrity is not a theoretical challenge, it is a daily reality for engineers, maintenance leads, and consultants operating in harsh, unforgiving environments. The most valuable lessons are not found in manuals, but on-site: at remote metering stations, along buried pipelines beneath unpredictable terrain, and in coastal terminals exposed to constant humidity and salt spray. In these scenarios, passive protection becomes the first and most critical line of defense against corrosion.

Field-proven systems developed by Trenton Corporation, such as advanced wax-based wraps and specialized primers, have demonstrated long-term effectiveness in preserving critical components under aggressive atmospheric and underground conditions. These solutions are trusted in complex operational settings where downtime is not an option, offering practical durability and minimizing the need for disruptive interventions.

Protection in Buried Pipelines

In areas where pipelines cross clay-rich, acidic, or chloride-heavy soils, choosing an effective passive protection system can be the difference between a stable operation and a multimillion-dollar loss due to leakage or structural failure. A well-proven approach involves systems made up of high-performance primers, filling mastics, and outer wraps designed to resist ground moisture.

Within this context, many operators have turned to technologies that use microcrystalline wax-based protective tapes, applied alongside penetrating primers. One of the most widely recognized solutions in this space is Trenton Corporation’s Wax-Tape® system, which has delivered outstanding results in measurement stations, buried valves, and critical crossings, even under high humidity and chemically aggressive soils. Its ease of installation and stable behavior under thermal and chemical cycling make it a key tool for predictive maintenance and risk management.

Marine and industrial environments

In coastal installations or port areas, high salinity and constant humidity create a highly aggressive environment. Added to this is the atmospheric pollution found in petrochemical complexes or refineries. In these settings, passive protection must resist not only electrochemical corrosion but also physical impact and vibration. Here, external wraps like MC Outerwrap or Poly-Ply, developed by Trenton Corporation, act as mechanical barriers complementing internal anti-corrosion systems.

Wax-Tape® systems from Trenton Corporation have consistently proven effective in protecting exposed structures such as pipe supports, flanged joints, and transition zonesespecially in harsh marine and industrial environments where durability and ease of application are critical.

These alternatives not only preserve infrastructure, but also strengthen data-driven decision-making by integrating with inspection routines, planned maintenance, and predictive maintenance strategies. A well-implemented passive strategy is, at the end of the day, an investment in operational resilience.

This short demonstration shows how the Wax-Tape® system from Trenton Corporation can be applied efficiently to a straight pipeline. Its flexibility allows technicians to work confidently in challenging field conditions without the need for specialized equipment.

Anticorrosion wraps application procedures

Advantages of passive protection vs. active alternatives

Selecting between passive and active protection methods is more than a technical matter, it’s a strategic choice that impacts long-term performance and reliability. Passive solutions, such as advanced coatings and anti-corrosion wraps, offer a clear advantage in terms of maintenance and monitoring: they require minimal intervention and operate independently of external power sources or continuous monitoring systems.

Unlike cathodic protection, which demands electrical design, regular inspection, and constant adjustments to remain effective, passive systems act as immediate physical barriers, reducing the metal’s exposure to aggressive environments. This translates into lower operational costs, less need for on-site specialized personnel, and a significant reduction in failure risks due to oversight or system disconnection.

When considering full lifecycle costs, well-implemented passive solutions are not only competitive—they are more efficient and sustainable in the long term, particularly in remote or hard-to-access areas.

Conclusions

Corrosion doesn’t offer second chances. Once structural deterioration begins in a critical pipeline or metallic support, reversing the damage becomes a costly, invasive, and often high-risk operation. That’s why today’s decisions on coatings, primers, or wrapping systems are not just technical detailsthey are strategic choices with direct impact on sustainability and operational continuity.

Adopting a preventive culture based on passive protection means anticipating the harshest and most complex scenarios. It means operating with foresight, where each applied barrier represents hours of productive uptime, avoided incidents, and preserved assets. Above all, it means embracing the technical responsibility of safeguarding structures that must withstand years of exposure without compromising function, safety, or structural integrity.

Protecting from the start is operating smartly. Choosing systems tailored to the operating environmentsuch as those developed by experts like Trenton Corporation is a decisive step toward a more resilient, cost-effective, and sustainable lifecycle management of industrial assets.

References

- ISO 9223:2012 — Corrosion of metals and alloys — Corrosivity of atmospheres — Classification, determination and estimation.

- NACE SP0508-2017 — Standard Practice for External Corrosion Direct Assessment (ECDA) Methodology

- Revie, R. W., & Uhlig, H. H. (2008). Corrosion and Corrosion Control (4th ed.). Wiley.

- About Corrosion Standards.

- NACE SP0169 and its role in external corrosion control in pipelines https://inspenet.com/en/articulo/nace-and-its-role-in-corrosion-control

FAQs about passive corrosion protection

What is the key difference between passive protection and cathodic protection?

Passive protection uses coatings, primers, and wraps to isolate the metal from the corrosive environment. It does not require external power or constant monitoring. In contrast, cathodic protection applies an electrical current to reduce corrosion potential, requiring active systems, specialized maintenance, and continuous monitoring. In remote or hard-to-access locations, passive protection offers a simpler and more sustainable solution.

What are the benefits of passive protection in hard-to-access areas?

In locations such as remote metering stations, buried pipelines, or offshore installations, where regular maintenance is costly or complex, passive systems reduce the need for intervention. Technologies like Trenton Corporation’s Wax-Tape® system allow for fast application without abrasive cleaning or special conditions, extending asset lifespan without disrupting operations.

How do I know if my asset requires specialized corrosion protection?

It is important to assess factors such as geographic location, soil type, exposure to humidity or salt fog, and maintenance accessibility. Critical assets in coastal areas, acidic soils, or outdoor environments require tailored strategies, such as high-performance primers and microcrystalline wax coatings.

Is surface preparation necessary before applying a passive solution?

Yes. Although systems like Wax-Tape® allow application with minimal preparation, removing visible contaminants is recommended to improve adhesion and prevent early failure. Surface preparation, even without blasting, is a critical step in the predictive maintenance cycle.

What type of maintenance does a well-implemented passive system require?

In general, passive systems require periodic visual inspection, especially at vulnerable points such as flanges, welded joints, and soil-air interface zones. These systems are designed to minimize interventions, making them ideal for long-term operations with limited on-site maintenance resources.