Metal corrosion is one of the most studied phenomena in materials science, as it represents a constant challenge for industry, engineering, and modern technology. From the earliest uses of copper, gold, and iron to the implementation of sophisticated cathodic protection systems, the history of corrosion reflects the advancement of scientific knowledge and the economic impact of this phenomenon.

This article analyzes the most relevant milestones in the understanding of the history of metal corrosion, from the initial discoveries in the 18th century to the technological developments applied in the 20th century, with special emphasis on the research that marked the evolution of electrochemical theories and the practical solutions adopted by industry.

Why did early metals not corrode?

The first metals used by ancient civilizations were those that could be found in their native (noble) state, such as gold, copper, and silver, or those that could be easily reduced to their elemental state. As a result, they did not tend to easily transition to a combined state, which significantly limited corrosion problems.

The scenario changed radically with the introduction of iron. Its high reactivity and tendency to form compounds such as oxides revealed the true magnitude of the problem of metal corrosion, which would become the subject of scientific research in the centuries that followed.

How has corrosion research evolved?

Early observations in the 18th century

In the 18th century, researcher Austin made one of the first systematic observations on the effects of water in contact with iron in 1788. He noted that water, initially neutral, tended to become alkaline after interacting with the metal. He explained this phenomenon as a phenomenon caused by the generation of sodium hydroxide as a cathodic product within the electrochemical reactions characteristic of corrosion in saline environments (Cottis), 2000).

This finding was an important precedent, as it showed that corrosion was not simply a chemical process of dissolution or direct combination with oxygen, but involved more complex transformations associated with the behavior of iron in aqueous environments.

Later, in 1819, French chemist Louis Jacques Thénard advanced the understanding of the phenomenon by proposing that corrosion should be interpreted as an electrochemical process. This approach represented a significant milestone, as it laid the foundations for the development of a more solid theoretical framework around the mechanisms of metal degradation.

Thénard’s observations paved the way for a new scientific perspective in which corrosion occurred as a result of oxidation-reduction reactions distributed across different areas of the metal surface, with the formation of interdependent anodic and cathodic regions. This interpretation marked the beginning of the transition towards a more rigorous and quantifiable explanation of the problem of corrosion, which would continue to develop throughout the 19th and 20th centuries (Cottis, 2000).

Faraday and the connection between chemistry and electricity

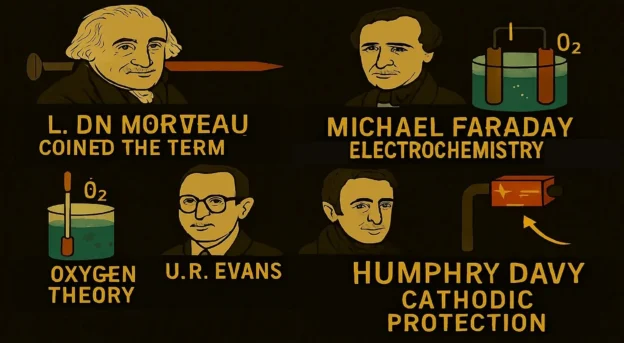

Between 1834 and 1840, Michael Faraday conducted a series of experimental investigations that transformed the understanding of electricity and chemistry. He demonstrated that chemical reactions could generate electric currents and that electricity could induce chemical changes in electrolytes, establishing a conceptual link between the two fields.

He contributed to the understanding and control of corrosion by discovering the laws of electrolysis, which establish that the amount of metal deposited or dissolved is proportional to the electrical charge passing through the solution. Furthermore, he also introduced fundamental concepts such as electrode, electrolyte, anode, cathode, cation, and anion, which remain in use today as the basic terminology of electrochemistry.

These discoveries marked the history of corrosion and were fundamental to the study of metal corrosion, showing that it was not just a superficial deterioration, but an electrochemical process where anodic and cathodic regions interact through an electrolyte. This approach made it possible to understand phenomena such as localized dissolution, oxide formation, and the influence of factors such as the conductivity of the medium or the presence of electrolytes, laying the foundations for modern electrochemistry.

Advances in the 19th century: Edison and cathodic protection

In 1890, Thomas A. Edison patented a rudimentary cathodic protection system based on the application of impressed currents using an inert graphite anode. Although his approach was mainly experimental and limited by the technology of the time, this method laid the conceptual foundations for modern cathodic protection. The central idea was to counteract the natural corrosion of metals by converting metal surfaces into cathodes and preventing their oxidation by supplying them with an external electric current.

This historic breakthrough was fundamental because it introduced the principle of electrochemically controlling corrosion, which is now widely applied in water and oil pipelines, ship hulls, offshore platforms, and other critical infrastructure. Today’s more sophisticated and automated systems retain the same basic concept that Edison developed: protecting metal structures by reversing the electrochemical reactions responsible for their deterioration.

In the early 19th century, Humphry Davy’s (1810–1820) work on cathodic protection and Michael Faraday’s (1830s) work on the laws of electrolysis consolidated the idea that the corrosion of iron in the presence of water and oxygen was an electrochemical process.

Throughout the second half of the 19th century, the anodic mechanism (dissolution of iron as Fe²⁺) and cathodic mechanism (reduction of oxygen in water) were detailed, laying the modern foundations for understanding corrosion in iron exposed to humid air.

Theories from the early 20th century

In 1908, a theory was developed that acids were primarily responsible for corrosion. In particular, carbonic acid was attributed as the source of rust on iron.

Around 1900, the hypothesis also arose that hydrogen peroxide acted as an intermediary in the corrosion process. It was later established that this compound forms when there is an excess of oxygen at the cathode. However, in 1905, Dunstan, Goulding, and Jowett demonstrated that iron exposed to water and oxygen could corrode even without the presence of carbonic acid, partially refuting the previous theory.

International research and consolidation of theories

In 1907, American researchers Walker, Cederholm, and Bent accepted corrosion in neutral liquids with the participation of oxygen as a cathodic stimulator.

In 1910, Germans Heyn and Bauer conducted extensive research on iron and steel, establishing for the first time quantitative measurements of corrosion rates in different media. These studies confirmed that the attack on iron intensifies in contact with a more noble metal, while contact with a more active metal can offer partial or total protection. This phenomenon had already been anticipated in 1824 by Sir Humphry Davy, who proposed protecting the copper of British ships from the action of seawater by means of iron or zinc.

In the field of protective coatings, thanks to advances in nanotechnology, research, and production of graphene coatings, a new anti-corrosion barrier technology has been developed. These products incorporate graphene oxide (GO) and clay, nanotechnological additives that provide high protection against corrosion by creating tortuous paths that hinder the diffusion of oxygen and water molecules to the metal surface, thus preventing the onset of deterioration processes.

The mechanism of action of these coatings is based on two main pathways: as a physical barrier, greatly limiting the penetration of aggressive species, and as electrochemical inhibitors, increasing electrical and ionic resistivity, thereby interrupting the corrosion cycle. This dual strategy positions them as highly effective solutions for the protection of metal structures in demanding industrial conditions.

Impact on world war I

During the war of 1914-1918, corrosion of marine condenser tubes and tow cables in maritime environments became a critical problem for the British Navy, to the point of causing more concern than the enemy fleet itself.

Research by the Corrosion Committee of the Institute of Metals and the British Non-Ferrous Research Association led to the development of new corrosion-resistant alloys, substantially improving the situation.

Advances in the 20th century

In 1938, Belgian Marcel Pourbaix revolutionized the field with his contributions to applied thermodynamics, introducing the diagrams that bear his name. These diagrams graphically represented the stability of metals as a function of pH and electrochemical potential, constituting an essential tool in materials science.

At the same time, the oil, and shipbuilding industries developed advanced corrosion protection techniques, promoting the practical application of the knowledge acquired.

Conclusions

Research into metal corrosion has evolved from Faraday’s fundamental studies and Edison’s early cathodic protection systems to today’s multidisciplinary approaches that integrate electrochemistry, microbiology, advanced materials, and monitoring technologies. This enables us to understand the mechanisms of deterioration and design effective prevention strategies.

Historical and recent advances in metal corrosion control have been instrumental in protecting critical infrastructure, optimizing the service life of materials, and reducing industrial costs, highlighting the importance of continuing to develop sustainable and technologically sophisticated solutions.

References

- Cottis, R. A. (2000). Electrochemical corrosion. In C. C. Nathan (Ed.), Uhlig’s Corrosion Handbook (2nd ed., pp. 51–54). Wiley-Interscience.

- Bockris, J. O’M., & Reddy, A. K. N. (1970). Modern electrochemistry: An introduction to an interdisciplinary area (Vol. 1). Plenum Press.

- Revie, R. W. (Ed.). (2000). Uhlig’s corrosion handbook (2nd ed.). Wiley-Interscience.

Frequently Asked Questions (FAQs)

Which metals were the first to be used without serious corrosion problems?

Mainly gold, copper, and silver, as they could be found in their native state and did not easily combine with other elements.

Who established that metal corrosion was an electrochemical phenomenon?

French scientist Louis Jacques Thénard, in 1819.

What was Michael Faraday’s contribution to the study of metal corrosion?

He demonstrated the relationship between chemical reactions and the generation of electric currents, laying the foundations for electrochemistry.

How important was Pourbaix’s work in 1938?

He introduced potential-pH diagrams, which are fundamental for predicting the stability of metals and their reactions in different environments.

What modern techniques are used to prevent corrosion?

Cathodic protection, specialized coatings, the use of resistant alloys, and real-time electrochemical monitoring.