In harsh industrial environments, where durability, chemical resistance and ease of maintenance are essential, choosing the right coating can make a big difference. Two of the most effective options for coating industrial assets are two synthetic materials: epoxy resin and polyurea.

Although often confused because of their similar applications, the two systems differ in their composition, properties and performance. In addition to offering safety, these coatings provide critical features in industries that demand high standards of cleanliness and resistance.

In the epoxy vs polyurea comparison, factors such as surface type, intended use of the space, environmental conditions and budget directly influence which of the two systems is more efficient. Here’s a look at which performs better in demanding industrial environments.

Introduction to industrial coatings

What is an epoxy coating?

An epoxy coating is a surface protection system formulated from epoxy resins, high performance thermosetting polymers that, when combined with hardeners (usually polyamines), undergo a curing process by chemical crosslinking. This process results in a solid film with excellent adhesion, high mechanical strength and outstanding physical-chemical properties.

Their high thermal stability and resistance to corrosive substances make them particularly suitable for industrial environments, automotive installations, and structural systems where durability and long-term reliability are required.

Molecular structure of epoxy resins

Epoxy resins are high molecular weight compounds with two or more epoxy groups in the molecule and low relative molecular weight, the best known being bisphenol A glycidyl ether epoxy resin, commonly known as bisphenol A epoxy resin, is the most important type. It accounts for 90% of the total production of epoxy resins.

What is a polyurea coating?

Polyurea coating is a surface protection technology consisting of the reaction of an isocyanate with an amine. This coating is characterized by its rapid formation by hot polymerization (usually by spraying with high pressure and temperature equipment), which allows solidification in seconds and effective adhesion on various substrates, such as concrete, steel and wood.

Polyurea has excellent chemical, mechanical and abrasion resistance, as well as outstanding impermeability. For these reasons, it is widely used in industrial sectors that require extreme protection against aggressive agents, such as the petrochemical industry, mining, hydraulic infrastructure and construction.

Another crucial advantage is its elasticity and durability, even under extreme weather conditions or UV exposure. Unlike other coatings, polyurea can be applied without primers in many cases and is ideal for projects where a quick return to service is required.

Molecular structure of polyurea

Polyurea is a type of elastomer produced by the reaction of a diisocyanate and a synthetic resin with amide groups through a polymerization process known as step growth. It can be aromatic or aliphatic in nature. Example: Polyurethane.

Properties of epoxy resin and polyurea coatings

Chemical resistance

Epoxy coatings offer excellent protection against a wide range of corrosive agents, especially in environments where there is constant exposure to hydrocarbons, chlorinated solvents and strong acids. However, they may degrade upon prolonged exposure to certain alkaline products or highly concentrated acids if not specifically formulated for such environments.

In contrast, polyurea has a more balanced chemical resistance, being highly resistant to dilute acids, alkalis, salts and common industrial chemicals1. Although in some cases its point resistance may be lower than that of certain specialty epoxies, its flexibility, lower permeability and rapid cure offer advantages in aggressive, wet environments.

Thermal resistance

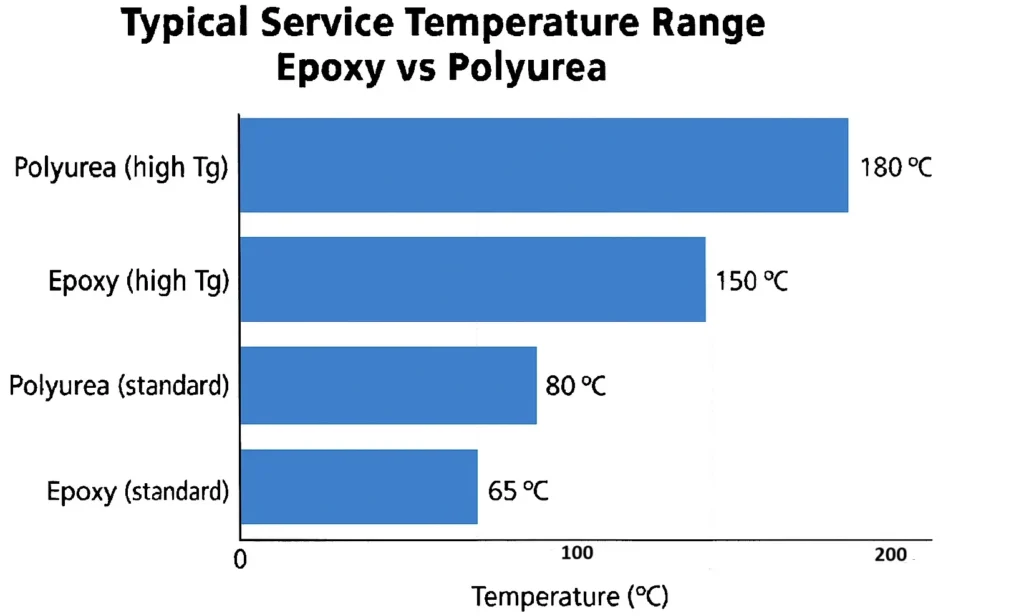

Epoxy resins withstand prolonged temperatures up to 45 °C, and up to 70 °C, however, any temperature between 20 °C and 90 °C (68 – 195 Fahrenheit) can cause changes in the molecular structure of this material; consequently, the resin softens and distorts, losing its initial hardness (similar to that of glass). Some special formulations, such as modified or high-temperature (Tg) epoxies, can reach 120-150 °C, without wearing out and without losing their initial properties4, but this is not common.

It is important to note that these thermal properties can be modified depending on the nature, concentration and distribution of the material added to the epoxy resin3.

While polyurea is immune to temperature changes between -40º and 180º and retains its elastic properties without breaking or softening, allowing easy transition of fractures and cracks in concrete and metal surfaces5.

Substrates such as metal roofs often expand and contract with temperature changes. Polyurea expands and contracts with the roof rather than fighting against it, offering total protection against weather changes.

In summary: In its standard version, polyurea has higher thermal resistance and stability against sudden temperature changes. Epoxy can overcome it only in high Tg formulations designed for extreme heat, but that is a more specialized product.

Performance in harsh industrial environments

Epoxy requires controlled conditions for application and curing. Moisture during the process can adversely affect its adhesion and generate defects such as blistering or delamination.

Polyurea can be applied even in humid conditions and extreme temperatures, without compromising its adhesion or curing time. This property makes it ideal for environments exposed to the weather, such as outdoor plants or buried tanks.

Adhesion and surface compatibility

To ensure optimum adhesion and avoid premature failure, epoxy requires more rigorous surface preparation. In the case of polyurea, this type of coating shows better performance on irregular surfaces, such as previously treated corroded metal or even wet concrete.

Durability and maintenance

While epoxy is known for its good initial mechanical and chemical resistance, its long-term durability can be compromised by factors such as prolonged exposure to UV rays, constant humidity or aggressive chemicals2. Over time, it can become brittle, lose adhesion or discolor, especially in outdoor applications or in environments with intense thermal changes.

Its highly cross-linked chemical structure gives it exceptional resistance to wear, abrasion, weathering, and aggressive thermal cycling, maintaining its physical properties even after years of continuous exposure. This longevity translates into a substantial reduction in maintenance costs, as it does not require frequent reapplications or extensive repairs.

The following table shows a summary of epoxy vs. polyurea properties:

| Property | Epoxy | Polyurea |

|---|---|---|

| Viscosity (cps) | 1,500 – 15,000 | 500 – 2,600 |

| Density (g/cm³) | 1.10 – 1.60 | 1.05 – 1.50 |

| Mixing ratio (weight) | 100:9 – 100:100 | 100:16 – 100:93 |

| Dielectric strength (KV/mm) | 15 – 20 | 0.7 – 25 |

| Handling time (min) | 6 – 120 | 15 – 60 |

| Gelling time (min) | 10 – 90 | 30 |

| Hardness (Shore) | D80 – D90 | A75 – D40 |

| Color | Transparent / Black | Transparent / Amber / White / Black |

| Thermal conductivity (W/m-K) | 0.75 | 0.2 – 0.7 |

| Operating temperature (°C) | Approximately 60 – 65 °C (140-150 °F) | Range from -40 °C to 180 °C depending on formulation |

Limitations and considerations in epoxy vs polyurea coatings

Epoxy resins and hardeners can cause skin irritation, skin sensitization and respiratory problems, especially in confined spaces without adequate ventilation. Some hardeners, such as amines, also exhibit significant toxicity through prolonged contact or inhalation. From a technical point of view, epoxies require controlled environmental conditions for optimum curing, since the presence of humidity or low temperatures can generate defects such as free amines, blush or loss of adhesion.

In the case of polyurea, although its versatility and rapid polymerization are clear operational advantages, these same characteristics represent technical challenges. Extremely fast curing requires strict control of temperature, humidity and pressure during application, as well as the use of specialized high-pressure spray equipment. Its high reactivity means that, once mixing has begun, the working margin is minimal, increasing the likelihood of material waste and misapplication failures without highly trained personnel.

From a safety point of view, the handling of isocyanates, essential components of polyurea, involves toxicological risks, especially by inhalation of vapors and aerosols, which makes adequate ventilation, the use of filter respirators and complete eye and skin protection indispensable.

In both cases, the implementation of industrial safety protocols, training of personnel and the implementation of a safety plan are essential to mitigate risks and guarantee the durability of the coating.

Conclusions

In the industrial environment, both epoxy and polyurea offer high-performance solutions, but their strengths are adapted to different scenarios. Epoxy stands out for its thermal resistance and performance in controlled conditions, making it a reliable choice for interior areas and processes where stability against elevated temperatures and specific chemical agents is a priority. However, its sensitivity to moisture during application and its lower tolerance to weathering limit its versatility.

Polyurea, on the other hand, offers clear advantages in speed of curing, moisture resistance and adaptability to various surfaces, even in extreme weather conditions. Its elasticity and durability reduce long-term maintenance costs, although it requires specialized equipment and trained personnel.

From an objective point of view, polyurea is the most efficient choice for exposed industrial environments with high humidity or the need for rapid return to service, while epoxy is more suitable for controlled environments with high thermal demands.

References

- https://concreteinspirations.ca/the-rise-of-epoxy-floor-coatings-in-industrial-spaces/

- https://www.croccoatings.com/polyurea-vs-epoxy-chemical-resistance-compared/

- https://ciqa.repositorioinstitucional.mx/jspui/bitstream/1025/361/1/Esdras%20David%20Juarez%20Alonzo.pdf

- https://www.rodator.com/resina-epoxi-resistencia-a-las-altas-temperaturas/

- https://paxcon.com/mx/paxcon-mx/