Table of Contents

- Quality control begins at production

- Diesel SCR systems: Architecture and operating principles

- What is an SCR Catalyst?

- NOx reduction with DEF indiesel engines

- Impact of DEF Contamination on SCR

- Does low quality DEF affect power and performance?

- Best practices: DEF storage and quality control

- Innovations in DEF and SCR technology

- Conclusions

- References

Diesel Exhaust Fluid (DEF) is an aqueous solution of high-purity urea formulated for Selective Catalytic Reduction (SCR) systems. According to international standards (ISO 22241), DEF contains 32.5% high-purity urea and 67.5% deionized water.

The urea component must be free of biocides, formaldehyde, and other impurities that could degrade SCR catalysts or cause deposits in dosing hardware. At the molecular level, urea (CO(NH₂)₂) thermally decomposes into ammonia (NH₃) and isocyanic acid (HNCO) under controlled dosing and high exhaust temperatures, a reaction exploited for NOx reduction.

Unlike fuel additives, DEF is not burned; it acts as a reactant in post-combustion emissions control. In modern diesel engines equipped with SCR, DEF is injected into the exhaust stream upstream of the catalyst.

There, the ammonia generated by urea decomposition acts as a selective reactant, converting harmful nitrogen oxides (NO and NO₂) into diatomic nitrogen (N₂) and water vapor (H₂O) through surface reactions on a metal-oxide catalyst bed. Injection rate control, exhaust gas temperature, and catalyst condition determine SCR efficiency.

Quality control begins at production

Industrial-grade urea is refined through crystallization and ion-exchange purification to meet specific SCR criteria, limiting biuret, aldehydes, and particulates.

The strict ISO 22241 standard ensures consistent chemical composition, crystalline behavior, and thermal stability. Deviations can result in poor decomposition kinetics or ammonium nitrate formation, directly affecting SCR performance and emissions compliance.

Diesel SCR systems: Architecture and operating principles

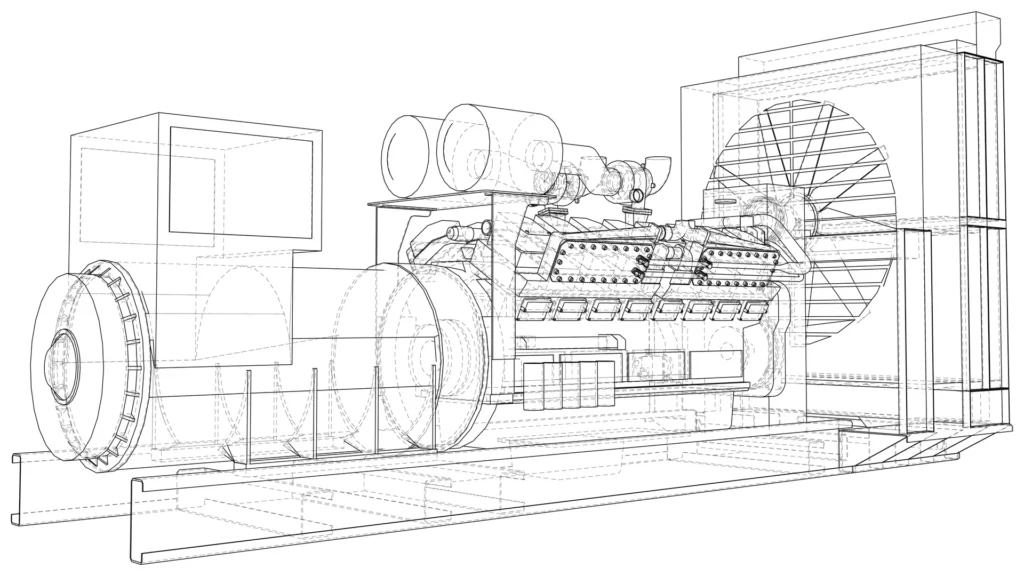

Selective Catalytic Reduction (SCR) is an advanced emissions control process designed to meet strict NOx regulations, such as EPA Tier 4, Euro VI, and emerging global standards. An SCR system consists of a DEF dosing module, a mixer, one or more catalytic units, and sensors.

The dosing module is electronically synchronized with the engine control unit (ECU) to modulate DEF injection based on load and exhaust parameters. Precision is critical: insufficient ammonia results in incomplete NOx reduction, while excessive ammonia leads to slip, i.e., uncontrolled NH₃ emissions that can damage downstream components or violate regulations.

What is an SCR Catalyst?

It usually consists of a ceramic or metallic substrate coated with basic metal oxides (e.g., vanadium-tungsten-titania) or zeolites with copper or iron active sites. These materials facilitate reduction reactions over a wide temperature range (typically 200–450 °C).

Modern systems often use dual-stage catalysts optimized for low- and high-temperature regimes, improving conversion efficiency across all operating cycles, from idle to high load.

Operational performance depends on precise DEF injection control, uniform mixing with exhaust gases, and maintaining catalyst surface integrity. Integration with upstream and downstream NOx sensors allows closed-loop feedback, dynamically adjusting DEF flow to maintain target NOx conversion efficiency (>90% in many systems).

Advanced diagnostics continuously monitor injector performance, DEF quality signals from conductivity/temperature sensors, and catalyst condition to prevent degradation.

NOx reduction with DEF indiesel engines

Diesel engines inherently produce more NOx due to high combustion temperatures and pressures favoring NO formation. To meet modern emission standards, OEMs increasingly rely on SCR to achieve NOx targets below 100 mg/km in heavy-duty and passenger applications.

When DEF decomposes into ammonia and mixes with exhaust gases, a series of catalytic reactions selectively reduce NO and NO₂ to benign N₂ and H₂O. Key reactions include:

- 4NO + 4NH₃ + O₂ → 4N₂ + 6H₂O

- NO₂ + 4NH₃ + O₂ → 3N₂ + 6H₂O

These reactions are temperature-dependent. At optimal SCR temperatures, conversion efficiencies usually exceed 90–95%. Below optimal temperatures, reactions slow, and byproducts such as ammonium nitrate or nitrous oxide may form, reducing performance.

Impact of DEF Contamination on SCR

DEF contamination is a critical degradation vector for SCR performance. Contaminants can include particulates, biuret, heavy metals, or microbial growth from improper storage, handling, or poor manufacturing.

These impurities can clog injector nozzles, cause corrosion, foul sensors, and poison the catalyst. Common symptoms include erratic DEF dosing, elevated NOx emissions, and diagnostic trouble codes (DTC) triggered by the vehicle emissions control system.

Even trace levels of contaminants like biuret or aldehydes can promote crystallization inside the dosing module or mixer, leading to restricted flow and erratic injection rates.

In worst cases, crystallized urea salts deposit on catalyst surfaces, reducing active sites and impairing conversion efficiency. This not only causes regulatory non-compliance but also potentially costly repairs, as catalyst replacement alone can exceed tens of thousands of dollars in heavy-duty applications.

With modern onboard diagnostics (OBD) continuously monitoring NOx sensor data, the ECU can detect degradation due to poor DEF quality. Engine power may be reduced as a protective strategy to limit emissions violations; this is especially common in vehicles with strict compliance requirements.

Maintaining DEF integrity through controlled storage temperatures, moisture-free containers, and appropriate transfer equipment is essential to prevent contamination.

Does low quality DEF affect power and performance?

Yes; in many modern diesel vehicles, DEF quality directly affects engine performance through emissions control logic. When the SCR system detects elevated NOx levels due to insufficient ammonia availability (from poor or contaminated DEF), the ECU may enter limp mode or reduce engine power.

This strategy reduces fuel injection or limits torque to decrease upstream NOx formation, giving the SCR system a better chance to manage downstream emissions.

Additionally, insufficient DEF dosing due to blocked injectors or crystal formation produces inadequate ammonia, resulting in elevated NOx readings. The ECU interprets this as inefficient combustion or sensor failure, potentially activating engine protection algorithms that limit performance.

Conversely, overdosing (from faulty quality sensors or incorrect DEF concentration) may cause ammonia slip, also triggering power reductions or emissions system shutdowns to protect hardware and prevent violations.

Practically, poor-quality DEF can mimic mechanical failure symptoms, with reduced engine power, increased fuel consumption, and frequent maintenance interventions. Advanced in-line conductivity, temperature, and refractive index sensors in DEF tanks and dosing modules help prevent these issues, ensuring fluid meets ISO 22241 specifications before injection.

Best practices: DEF storage and quality control

Diesel exhaust fluid must be stored and handled to preserve chemical purity and prevent microbial contamination. DEF is hygroscopic (readily absorbs water and airborne contaminants), so it must be protected from dust, dirt, and extreme temperatures.

Ideal storage is within 0–30 °C; exposure to subzero temperatures freezes DEF, although modern dosing systems and tanks include heaters to manage thawing crystals. High temperatures (>40 °C) accelerate ammonia volatilization and degrade water quality.

How should diesel exhaust fluid be stored?

Storage tanks must be sealed with DEF-specific components; carbon steel tanks or standard potable water fittings are prohibited due to corrosion risk and particle shedding.

Instead, tanks and transfer pumps must be made of stainless steel or engineered plastics resistant to urea solution chemistry. Regular cleaning with DEF-compatible agents and inspection of accessories prevent contaminants that could cause microbial growth or particulates.

Cross-contamination with diesel fuel, lubricants, antifreeze, or other chemicals must be avoided. Specific DEF transfer equipment (hoses, pumps, and nozzles) is essential to maintain purity.

Additionally, DEF quality control via conductivity and refractive index measurements before dispensing ensures concentration remains within ISO 22241 specifications. Fleet managers often implement quality audits, supplier checks, and batch testing to mitigate contamination risks.

Innovations in DEF and SCR technology

Recent advances focus on maximizing NOx conversion while reducing operational challenges. A key innovation is integrating advanced NOx sensors with machine learning-based control algorithms to optimize DEF injection in real time during transient cycles. These systems improve ammonia utilization efficiency, reduce DEF consumption, and minimize ammonia slip.

In materials science, next-generation catalysts use customized zeolites with nanoscale copper or iron exchange structures for higher activity at lower temperatures (<200 °C). This enhances effective NOx conversion during cold starts, historically a weak point in SCR systems.

Additionally, sulfur- and sintering-resistant coatings extend catalyst life, crucial for heavy-duty and off-road applications with long maintenance intervals.

Conclusions

Diesel exhaust fluid (DEF) has evolved from a simple consumable to a critical chemical reactant in modern emissions control architectures. Its proper understanding—from chemistry and quality requirements to contamination risks and SCR system interactions—is essential for engineers, fleet managers, and emissions specialists.

In an era of increasingly strict environmental regulations, mastering DEF and SCR technology ensures sustained diesel system performance, regulatory compliance, and responsible environmental management. Advances in DEF formulation, including stabilized ureas and anti-crystallization/microbial additives, significantly improve operational reliability, reduce dosing system failures, and enhance storage stability.

Finally, integration of in-line quality sensors and cloud-based diagnostic platforms supports predictive maintenance, maximizing SCR efficiency and lifetime throughout the vehicle’s operational cycle.

References

- https://www.iso.org/standard/68539.html

- https://enginetechforum.org