Introduction

Corrosion in solar panels represents a significant problem in the solar energy industry, caused by exposure to aggressive environmental conditions. Corrosion on PV modules will lead to a reduction in module power output and affect the entire output of your system. In this respect, advances in materials play an important role, especially in the manufacture of these components.

Materials have represented fundamental elements throughout human history, marking different stages that reflect the advances in their development. From the Stone Age to the Iron Age, each period has been associated with the predominant material of the time. In the 20th century, the focus on materials intensified, leading to what is known as the Materials Age. However, the beginning of the 21st century has seen a shift towards the era of nanomaterials, where nanoscale properties have gained significant importance in various applications.

The purpose of this article is to report on advances in the development of advanced materials to improve corrosion resistance in solar panels. Through the structure provided, it is intended to highlight the challenges and innovations in materials that address these challenges, and to highlight the positive impact of these advances on solar energy efficiency and sustainability. In addition, it seeks to provide a clear and understandable vision of how these new materials can contribute to a more promising future in the field of renewable energy.

What is solar photovoltaic energy and how does it work?

Solar photovoltaic systems are a technology designed for the generation of renewable energy, converting solar radiation into electricity through devices such as photovoltaic panels, thus allowing its immediate use in electricity consumption or its storage in batteries for later use.

These systems are composed of solar cells made of semiconductor materials, such as silicon. When sunlight strikes these cells, the photons release electrons in the semiconductor material, thus generating electric current. This process, known as the photovoltaic effect, is fundamental to the operation of photovoltaic systems and their contribution to the production of clean and sustainable energy.

What are the components of this technology?

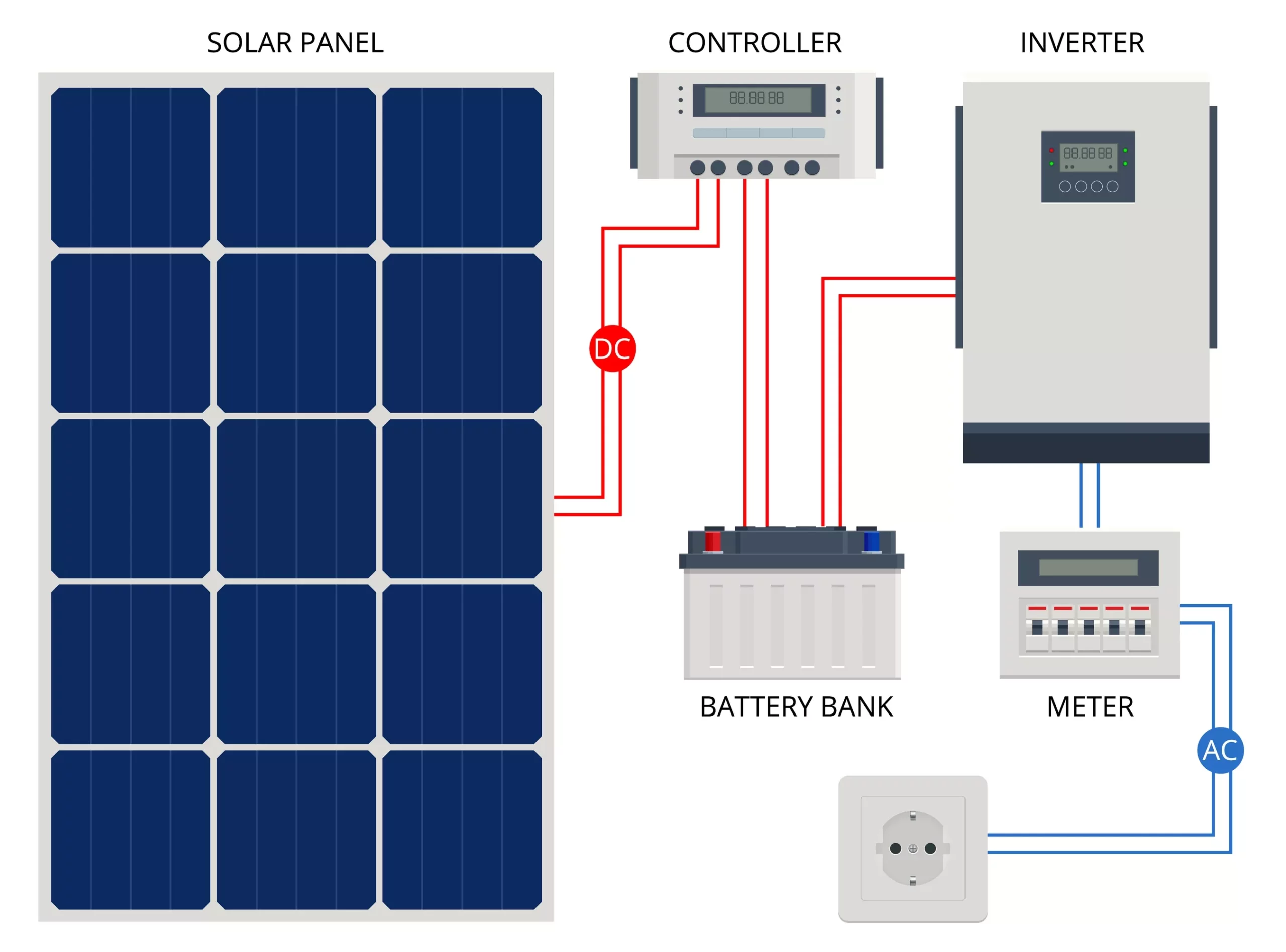

A photovoltaic system is made up of multiple fundamental components in the generation of renewable energy, which play a specific role in guaranteeing the efficiency and proper functioning of these systems. In its basic configuration, a photovoltaic system consists of several elements: PV cells, charge controller, inverter, grid connection and storage batteries.

- Photovoltaic cells are units that convert sunlight into electricity and are grouped into photovoltaic modules, which are made of semiconductor materials such as silicon and are essential for efficient energy production.

- The charge controller: Controls the flow of electricity between the solar panels and the batteries or the grid, ensuring safe and efficient charging of the batteries and protecting the equipment from overcharging or over-discharging.

- The inverter: Converts the direct current (DC) generated into alternating current (AC), used in most conventional electrical systems.

The grid connection allows the injection of surplus energy from the photovoltaic system, while the batteries store energy for use in times of low solar radiation.

Corrosion problem in solar panels and its impact on their performance and durability

Corrosion in modules is a significant problem that can negatively affect their performance and durability, due to the exposure to different adverse environmental conditions, such as humidity, acid rain, intense solar radiation and the presence of corrosive agents in the air, such as salinity in marine atmospheres or industrial pollution in urban environments.

When the materials that make up these prototypes corrode, they can experience degradation in their structure and functionality. For example, corrosion of electrical contacts can cause a decrease in the efficiency of solar energy conversion into electricity, resulting in a loss of performance. In addition, corrosion on frames or supports can compromise structural integrity, which could increase the risk of physical damage or premature failure, as shown in Figure 2.

Corrosion can also reduce the lifetime of solar panels, resulting in additional maintenance and replacement costs. Likewise, repair or replacement of corroded components can be costly and affect the long-term profitability of solar projects.

To ensure service life and efficiency, it is essential to prioritize protection against adverse environmental conditions, which cause corrosion and subsequent deterioration of solar module surfaces and components, compromising performance.

What factors cause corrosion?

Solar energy is a promising and growing renewable energy source, but faces significant challenges related to corrosion due to environmental factors. These challenges are especially relevant in areas where climatic conditions are extreme or where exposure to corrosive agents is high.

One of the main problems is exposure to humidity and rain, which can accelerate the corrosion process in the metal components of solar panels and other associated equipment. In addition, the presence of salinity in the air, especially in coastal areas, can increase corrosion, which is particularly problematic for marine solar installations.

Intense solar radiation can also trigger chemical reactions that lead to corrosion of materials, especially on exposed surfaces and protective paints. Extreme temperature changes, such as those experienced in desert climates, can also cause expansion and contraction in materials, which increases susceptibility to corrosion.

Another major challenge is the presence of atmospheric pollutants, such as industrial gases and combustion residues, which can deposit on solar panel surfaces and accelerate corrosion.

To address these difficulties, it is important to develop advanced materials that are highly resistant to corrosion and capable of withstanding long-term adverse environmental conditions. In addition, regular maintenance and careful inspection is required to identify and mitigate any damage caused by corrosion.

Advances in corrosion-resistant materials for solar panels

In order to extend the lifetime of metallic structures under weathering, corrosive or high salinity environments, materials with high resistance to deterioration are required. Currently, advanced materials are being developed that offer increased corrosion resistance. These materials use innovative technologies, such as nanotechnological coatings, which create barriers that are almost impermeable to corrosive agents. Composite materials and special alloys that can withstand extreme environmental conditions without degrading are also being explored.

- Nanotechnological coatings: form anti-corrosive barriers impervious to corrosive agents, extending the lifetime of solar modules.

- Composite materials: Composite materials offer durability and corrosion resistance in solar panels under extreme conditions.

- Magnesium-Aluminium-Zinc alloy (MAC) coated steels: These have the property of self-repairing their coating when the steel substrate is exposed due to scratches, punctures or cuts that leave the edges exposed.

The development of these advanced materials not only improves durability and performance, but also contributes to the expansion and efficiency of solar energy as a renewable energy source. By reducing maintenance costs and increasing lifetime, these materials contribute to more efficient energy sustainability.

Conclusions

Solar energy offers numerous benefits to the energy sector; however, challenges associated with corrosion due to environmental factors must be effectively addressed to ensure the long-term durability and efficiency of solar installations. Advances in materials are critical to the future of solar energy. The use of advanced materials ensures stronger and more durable solar panels, contributing to a more sustainable world.

Corrosion in solar panels represents a significant challenge that can negatively impact their performance, durability and profitability. Therefore, it is critical to develop advanced materials that are corrosion resistant to ensure the efficiency and longevity of solar PV systems.

References

- Brakels R; “Solar panel maintenance: how often should they be inspected?”; Solarquotes Since; February 20, 2017.