Table of Contents

- What is cold pressure welding?

- Techniques for applying the cold pressure welding process

- Physical principle of cold welding

- Critical process requirements and conditions

- Advantages of cold welding

- Limitations and challenges

- Industrial applications

- Technological outlook

- Conclusions

- References

- Frequently asked questions: FAQs

Cold welding is a metallurgical process that allows two metal surfaces to be joined without the need for heat or filler material. Unlike traditional fusion welding methods, cold welding is performed entirely in the solid state, using the nature of the metal bond to form a continuous and strong joint.

This phenomenon, initially discovered during studies of metal contact in a vacuum, has found growing applications in microelectronics, aerospace engineering, electrical contact manufacturing, and advanced manufacturing, where precision and surface purity are essential.

What is cold pressure welding?

This type of cold welding is a process of joining materials in a solid state that uses mechanical pressure instead of heat to join the pieces. This method is generally performed at room temperature and is commonly used to join ductile non-ferrous metals such as aluminum or copper, creating a strong bond by plastically deforming the surfaces and forcing them into close contact.

This welding process was first discovered as a general phenomenon of materials in the 1940s. At that time, it was discovered that two clean, flat surfaces of similar metal would adhere strongly when in contact in a vacuum at just a few angstroms (there are 300 million angstroms in a centimeter), the interaction between free electrons and ionized atoms can occur at the atomic level, forming a bond that results in molecular fusion between the surfaces of the parts to be joined and, therefore, a weld.

Techniques for applying the cold pressure welding process

There are various application techniques for the execution of this type of process. Among the best known are cold welding of sheets and butt welding, which are described below:

Sheet cold welding

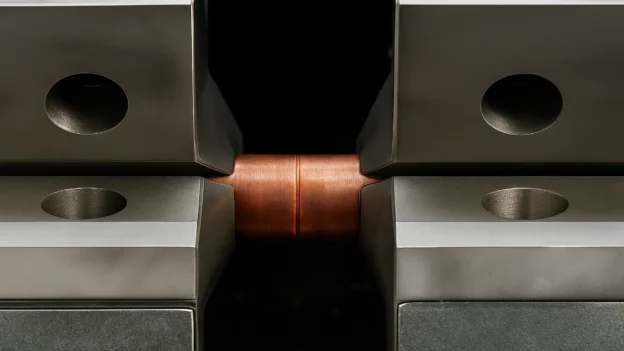

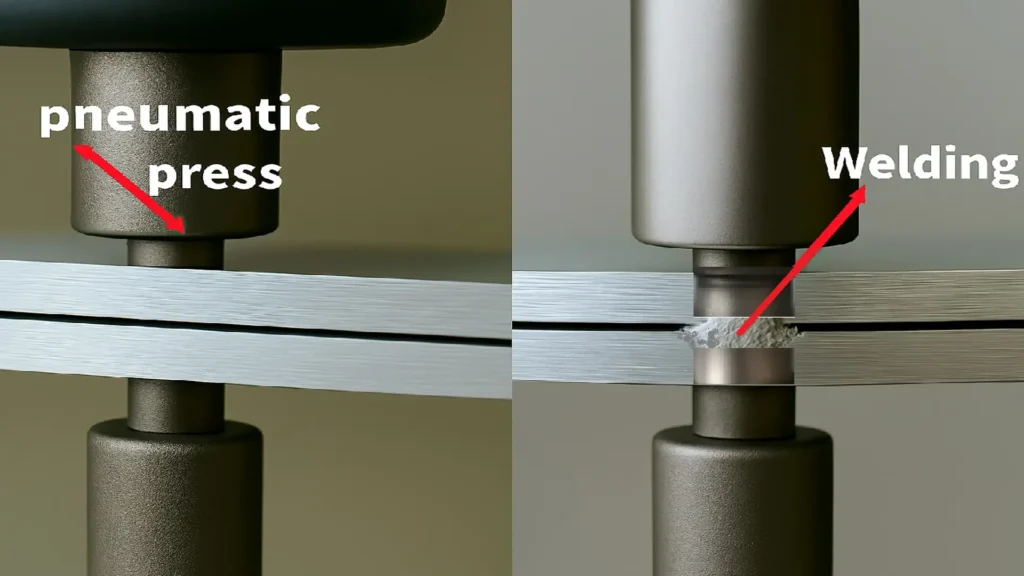

In this variant, the process is similar to resistance spot welding, with the difference that no electric current is applied. Two metal sheets are brought into contact and subjected to controlled pressure, so that the flow of material is oriented perpendicular to the direction of the pressure.

The result is a solid joint in which a slight reduction in thickness can be observed in the welded area, an effect characteristic of plastic deformation induced by compression. This method is mainly used to join thin sheets of ductile metals, such as copper or aluminum, in electrical or light structural applications.

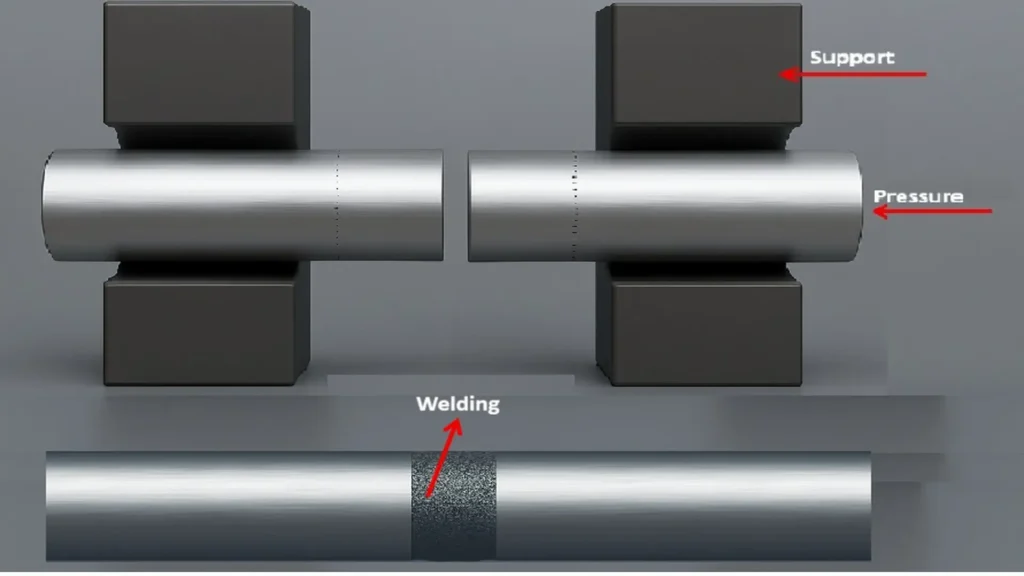

Cold butt welding

Cold butt welding consists of applying axial pressure to the ends of two bars or wires of similar or different materials, aligned in the same direction. The compressive force generates localized expansion in the contact area, forming a characteristic bulge or bulb.

As plastic deformation progresses, the clean surfaces come into close contact and metallurgical bonding occurs. This type of welding also increases the mechanical strength of the material due to cold work hardening.

These process variants are most successfully applied to non-ferrous, ductile metals with a low tendency to work harden, such as copper and aluminum. One of their most common applications is the manufacture of high-conductivity electrical connections and terminals.

To achieve a reliable joint, the surfaces must be exceptionally clean, which requires prior preparation by degreasing and wire brushing, carried out immediately before the process. In industrial practice, this type of joint is made using specialized equipment, such as multi-pass cold welding machines, which employ high-capacity hydraulic actuators (e.g., 250 kN and 630 kN), ensuring the pressure necessary to obtain a complete, defect-free joint.

Physical principle of cold welding

The basis of cold welding lies in metallic bonding, a type of chemical bond characteristic of metals. In these materials, atoms are not bound by traditional covalent or ionic bonds, but by a cloud of free electrons that move between positive nuclei. This shared electron cloud is responsible for conductivity, malleability, and, in the case of cold welding, the ability to form a continuous bond between surfaces.

When two metals are brought within a distance of just a few angstroms (one angstrom equals one ten-billionth of a meter), the attractive forces between free electrons and metal ions become significant. If the surfaces are perfectly clean and flat, free of oxides and contaminants, the potential barrier between the atoms disappears. The electron cloud becomes common to both pieces, and a metallurgical bond equivalent to that of the original material is produced.

In simple terms: when two pure metal surfaces touch at the atomic level, they interlock without melting, resulting in a solid weld without heat. An easier way to visualize this phenomenon is to imagine that, when two absolutely clean and perfectly flat metal surfaces are placed together at the atomic scale, the atoms of one integrate with those of the other without distinguishing boundaries. Under these ideal conditions, the resulting bond is identical in structure and strength to that of the parent metal itself.

How does a cold pressure welding machine work?

The cold pressure welding machine is designed to join non-ferrous metals through a controlled plastic deformation process, without the addition of heat or external material. Its operating principle is based on the application of hydraulic forces that generate a solid metallurgical bond between the surfaces in contact, eliminating the need for flux or thermal fusion.

They use an electronically or manually controlled hydraulic drive system, which allows the gripping and upsetting forces to be precisely regulated during the process. The welding cycle begins with the firm clamping of the parts (e.g., copper or aluminum conductors) using hydraulic clamps. Subsequently, the upsetting cylinders exert controlled axial pressure, causing localized plastic deformation and cold pressure welding.

Thanks to this principle, a continuous, high-strength metal joint is obtained without significantly altering the physical properties of the material. They operate in a range of applications depending on the hardness of the material and are ideal for manufacturing large cross-section wires and cables where a reliable electrical and mechanical joint is required.

Electronic welding machine

In electronic machines, the control and precision system guarantees the exact concentricity of the joined parts, maintaining alignment throughout the process. In addition, automated control removes burrs once welding is complete, improving surface finish and reducing subsequent operations.

The following video explains how the P1500 electrohydraulic cold pressure welding machine works, ideal for joining copper and aluminum from 15 to 30 mm. Powerful, precise, and energy efficient, it offers fast and economical joints without the need for heat. Courtesy of: PWM Cold Pressure Welding Machines.

Operation of an electrohydraulic cold pressure welding machine.

This P1500 electronic machine combines power and operational simplicity. It is easy to maintain and does not require highly specialized personnel, which improves industrial efficiency. Using an electrohydraulic system, it applies extreme controlled pressure from its upper head, where the welding die is housed. When the rods or wires are inserted, the P1500 compresses them with precision, removing impurities and ensuring a clean, solid bond.

Critical process requirements and conditions

The success of cold welding depends on compliance with very strict conditions in terms of preparation and the working environment. Surface cleanliness is an essential factor: surfaces must be completely free of oxides, oils, or contaminants, as any impurities can prevent effective metal contact. The pressure applied must be sufficient to plastically deform the microirregularities of the surfaces, promoting actual atomic contact.

Likewise, minimal surface roughness increases the effective contact area and improves the quality of the joint. This process is ideally carried out under vacuum conditions or in an inert atmosphere to prevent oxidation during the application of pressure. The most suitable materials are ductile metals such as copper, aluminum, gold, or lead, as they allow for greater deformation without fracturing. In general, the distance between the contacting surfaces must be less than 10 angstroms for the interatomic attractive forces to act effectively and achieve metallic cohesion.

Advantages of cold welding

The cold welding process offers significant advantages over conventional welding techniques. Since there is no heat input, there is no deformation, residual stress, or microstructural alteration in the base material. The resulting joint is highly pure, as the absence of melting prevents the incorporation of gases, inclusions, or contaminants. In addition, the method allows the joining of dissimilar materials, even those with very different melting points, which broadens its range of application.

Another notable advantage is its low energy consumption, as it does not require heat sources or electrical power, making it an efficient and sustainable process. Thanks to its precision and cleanliness, cold welding is particularly useful in the manufacture of microassemblies, sensors, and electronic components. In short, it is a technique that combines efficiency, cleanliness, and accuracy in contexts where structural integrity and the purity of the metal bond are critical.

Limitations and challenges

Despite its advantages, cold welding has practical limitations that restrict its large-scale implementation. Its main disadvantage lies in its high sensitivity to surface contamination, as the presence of oxygen, grease, or dust prevents the atomic contact necessary for bonding. In addition, the process often requires vacuum or inert atmosphere conditions, which are difficult and costly to maintain in high-volume industrial environments.

It is not suitable for fragile materials or those with very stable oxide layers, such as anodized aluminum, and its application on large parts requires precise control of pressure and alignment, which increases operational complexity. These limitations have driven research into new surface preparation techniques, such as plasma cleaning, laser treatment, and specialized chemical procedures, which seek to improve the quality of metal contact and expand the range of compatible materials.

Industrial applications

Cold welding is used in sectors where purity, precision, and structural integrity are essential. In the aerospace industry, it is used in the assembly of metal components under vacuum conditions, such as satellites or orbital instruments, where contaminants and thermal deformation are not permitted. In microelectronics, it is used to manufacture electrical contacts and microcables in high-precision chips or sensors.

In the electrical field, it allows copper, gold, or silver wires to be joined without resorting to thermal welding, ensuring excellent conductivity. It is also essential in vacuum technology, where it is used for the hermetic sealing of metal components free of residual gases, and in nanotechnology, where nanowelding processes are developed using controlled pressure to create metal joints on a microscopic scale.

Technological outlook

The technological prospects for cold welding are geared toward its integration with advanced manufacturing processes and its application on increasingly smaller scales. Among the most promising lines of development is the creation of metal nanojoints for microelectronic and nanomechanical devices. Likewise, the combination of cold welding with additive manufacturing opens up new possibilities in the integration of metal layers using controlled pressure, without the need for melting.

Surface optimization using laser or plasma treatments is an effective solution for removing oxides and contaminants without damaging the base material. Finally, research into smart joints points to the application of the process in shape memory materials and advanced alloys. These innovations consolidate cold welding as an emerging technology with high potential in fields such as robotics, microenergy, and smart materials engineering.

Conclusions

The phenomenon of cold pressure welding represents one of the purest expressions of metallic behavior at the atomic level. Without resorting to heat, metals can be joined together thanks to the natural interaction of their free electrons, forming a solid, continuous, and clean bond.

Cold welding not only challenges conventional intuition about welding, but also demonstrates how materials science and surface engineering can generate innovative solutions for high-precision industries.

At Inspenet, we promote technical knowledge that drives innovation. Understanding the principles of solid-state welding is key to designing stronger materials, cleaner processes, and technologies that transform the future of engineering.

References

- https://www.sciencedirect.com/topics/engineering/recrystallization-temperature

- https://dl.asminternational.org/alloy-digest

- https://weldguru.com/what-is-cold-welding/

Frequently asked questions: FAQs

Is pressure welding strong?

A cold welded joint will be as strong as the base metal if the necessary preparation is carried out correctly. The strength of the joint depends on the properties of the metal. Unlike other welding methods, the strength of a pressure welded joint cannot exceed the original strength of the metal.

How does pressure welding work?

Pressure welding joins metals at room temperature without applying heat or electrical energy to the joint. Applying force to the metal parts removes surface roughness and resolves minor irregularities. But the most important reason for applying pressure is to promote interatomic attraction between the two metal surfaces.

What is cold welding used for?

Cold welding is used in numerous industries, including aerospace, automotive, electronics, and manufacturing. It is most commonly used to weld wires, especially those made of different metals.

What are the prerequisites for applying cold welding?

The main prerequisites for cold welding are thorough cleaning of the metal surface and preparation of the joint geometry. Flat joint surfaces are most suitable, so it is recommended to flatten any irregularities in the shape.

Which metals can be pressure welded?

Metals to which pressure welding (cold welding) can be applied include copper, aluminum, lead, zinc, 70/30 brass alloy, nickel, silver, silver alloys, platinum, and gold. The 2xxx and 7xxx series of aluminum alloys can also be welded. These cannot be fusion welded because they tend to crack with heat and are difficult to join with welding methods other than cold welding.