Table of Contents

Industrial furnaces are key equipment in the petroleum refining industry, designed to provide controlled heat to fluids or gases and facilitate various chemical reactions and separation processes. The main function of an industrial furnace is to transform crude oil into lighter and more valuable fractions, such as gasoline, diesel, and petrochemical products. For efficient operation, the industrial furnace is composed of several fundamental elements. Optimization of these components is essential to ensure maximum performance. Among the key elements are:

- Combustion chamber: This is the heart of the furnace, where the fuel (usually natural gas, oil or a combination of both) is burned to generate heat. The temperature in this chamber can reach extremely high levels, depending on the required process. The design of the chamber is optimized to distribute the heat evenly and avoid hot spots that can damage equipment.

- Internal pipes (coil): Inside the furnace, the fluids or gases to be heated circulate through a series of pipes or coils that are in direct contact with the heat generated in the combustion chamber. The coils are designed to withstand high pressures and temperatures and are essential for transferring heat to the fluid efficiently.

- Burners: These are the devices responsible for the combustion of the fuel in the chamber. Burners are designed to mix fuel and air precisely, optimizing combustion and maximizing energy efficiency.

- Thermal insulation: The internal lining of the furnace is composed of insulating materials that prevent heat from escaping from the combustion chamber. This not only improves the thermal efficiency of the furnace but also protects the external structures of the furnace from heat damage.

- Chimney or flue: After combustion occurs, waste gases are expelled through a stack. A well-designed exhaust system is essential to safely remove hot gases and combustion by-products.

The purpose of this article is to analyze the factors that contribute to the formation of coke, a by-product that negatively impacts the efficiency and operational safety of industrial furnaces and other key assets in petroleum refining. Coke buildup reduces heat transfer capacity in furnaces, increasing operating costs and the risk of equipment failure.

Next, we will explore in detail the equipment most affected by coke formation, as well as advanced maintenance strategies, such as decoking and spalling, which are essential to maintain an efficient operation.

Industrial assets prone to coke formation

In the refining industry, industrial furnaces are the assets most susceptible to coke formation due to the high temperatures required to process heavy crudes. Some of the key assets facing this challenge are listed below:

- Vacuum furnaces: They are used to distill heavy crudes and residues, operating at high temperatures to separate lighter fractions. The high temperatures and prolonged contact time with the heavy hydrocarbons promote the formation of coke on the internal walls of the tubes.

- Visbreaker furnaces: These furnaces are designed to reduce the viscosity of the crude oil, but in doing so, they also increase the risk of coke formation due to elevated coil outlet temperatures (COT). Typical temperatures in these systems range from 750°F to 800°F.

- Cracking and delayed coking Furnaces: The heavy hydrocarbons in the furnaces are decomposed into lighter products. However, the high temperatures required to achieve this decomposition generate large amounts of coke, which must be removed regularly to avoid clogging the tubes.

- High vacuum furnaces: Used to distill heavy crudes under vacuum conditions, they are prone to coke formation due to the heavy compounds in the crude. Despite operating at lower temperatures, coke build-up in the tubes is common, affecting furnace efficiency and requiring frequent decoking to maintain optimum performance.

- Transfer lines: During the process of transporting crude oil and by-products through the plant, ovens and hot product transfer lines accumulate coke, reducing efficiency or even blocking the flow.

Identifying these assets is important as it allows targeting maintenance strategies to minimize coke formation and improve operational efficiency. Some important technical terms that will help to better understand coke removal techniques are explained below.

Definition of technical terms related to coke

- CCR (Conradson Carbon Residue): CCR is an indicator of the residual carbon content in a crude oil feed. The higher the CCR percentage, the higher the probability that the crude oil will form coke in the furnaces.

- COT (Coil Outlet Temperature): Coil outlet temperature refers to the temperature at which the fluid exits the furnace tube. As coke is formed, the TOC tends to increase due to the loss of thermal efficiency.

- Spalling: Is a process by which heat or sudden changes in temperature are applied to cause thermal expansion and contraction of the pipes, allowing the coke to be released from the internal surfaces.

- Decoking: This process consists of a method is the process of cleaning the tubes of a furnace to remove coke accumulation. It can be performed mechanically or thermally (spalling), and is essential to maintain the operating efficiency of the furnace.

- Coil: It is the set of pipes that transfers heat to the fluid or gas for heating processes and chemical reactions.

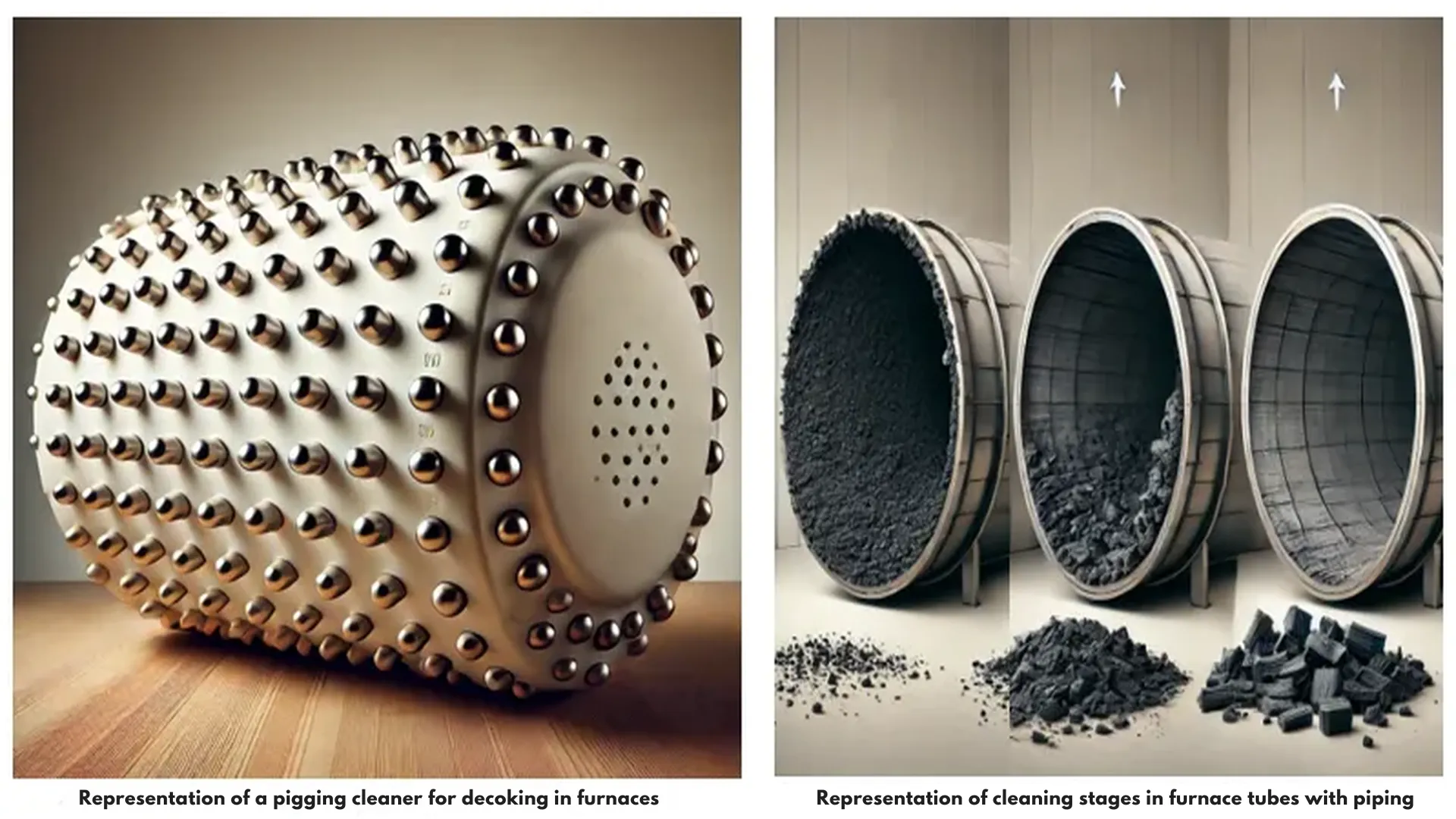

- Pigging: A cleaning technique that uses devices called “pigs” to remove coke deposits from internal pipelines. In addition, the intelligent pigs collect data on corrosion, wear, and possible obstructions in the pipes.

The Decoking process: Techniques and strategies

Decoking is an essential process for removing coke accumulated in industrial furnaces and other key assets. There are several decoking techniques, which can be divided into two broad categories: mechanical and thermal decoding.

- Mechanical decoking: In this method, specialized tools such as smart pigs are used, which are inserted into the pipes to scrape coke from the internal walls. The smart pigs not only clean the pipes but also collect data on the internal condition of the system, which allows the identification of areas where coke buildup is most severe and damage to the equipment may occur.

- Thermal spalling: This technique uses abrupt temperature changes to remove coke. The process begins with a controlled reduction in furnace temperature, followed by the injection of steam or water at high pressure. The thermal expansion and contraction generated during this process causes the coke to spall from the internal surfaces of the tubes.

Discover how mechanical decoking improves the efficiency of industrial furnaces in this video courtesy of CR3 Group:

Understanding these techniques is vital, as their correct implementation ensures extended equipment life and avoids costly damage. In addition, several factors influence the effectiveness of these methods, as will be detailed below.

Key factors affecting the formation and removal of coke in industrial furnaces

- Temperature: Control of this variable is critical; tube temperature plays a significant role in coke formation and removal. As coke accumulates, the tube skin temperature increases, which can affect the efficiency of the furnace. Maintaining the temperature during decoking is necessary to prevent damage and ensure efficient cleaning.

- Feed composition: Feeds high in metals, sodium, or heavy compounds are more prone to coke formation. Reducing these elements in the feed can reduce the rate of coke formation.

- Fluid velocity and residence time: The velocity of the fluid inside the tubes affects the residence time of the coke precursors on the tube walls. High velocities help reduce the residence time, which decreases the possibility of coke formation.

With a clear understanding of these factors, it is possible to optimize technologies that allow for more efficient coke disposal, as we will see below.

Technologies and best practices in Spalling and Decoking

Emerging technologies have radically transformed the decoking and spalling process, offering new tools to improve efficiency and reduce downtime of industrial furnaces. Among the most notable innovations is the use of infrared monitoring systems, which allow real-time control of temperatures along the furnace tubes.

These infrared systems accurately detect hot spots and areas where coke buildup is most severe. By continuously monitoring changes in temperature, operators can intervene before coke causes significant damage or interrupts operations, resulting in significantly reduced downtime.

These systems also help optimize maintenance cycles, allowing decoking to be performed at the most appropriate time, maximizing process efficiency, and minimizing the risk of overheating or structural failure.

Another key innovation in the decoking process are intelligent pigs. These devices are inserted into the furnace pipes and, in addition to removing accumulated coke by scraping, collect detailed data on the internal condition of the pipes. Smart pigs are equipped with sensors that measure the thickness of the pipe walls, identify areas of increased corrosion or wear, and detect potential blockages. This information is critical for operators to perform proactive maintenance, anticipating failures before they occur.

In addition, the data generated by the smart pigs allows decoking cycles to be planned more accurately, optimizing the cleaning frequency and improving the longevity of the furnaces. With detailed analysis of internal tube conditions, preventive strategies can be implemented, such as adjusting operating temperatures or modifying the feed composition, helping to reduce coke formation in the future.

These technologies allow operators to make informed maintenance decisions, reducing both downtime and the risks associated with coke formation.

Conclusions

Efficient coke management in industrial furnaces is important to ensure operational continuity, reduce costs and extend equipment life. Coke accumulation, if not properly addressed, can compromise furnace integrity, decrease thermal efficiency, and increase the risks of catastrophic failure. However, by implementing advanced decoking and spalling techniques, as well as adopting emerging technologies such as infrared monitoring and smart pigs, refineries can address associated problems more efficiently. this challenge more effectively.

The strategic use of new technologies ensures: safety, operational performance, and helps plants maximize productivity and reduce the economic impact associated with coke formation. A preventive and proactive approach is key to long-term success in the operation of industrial ovens.

These strategies enable more accurate and efficient intervention, optimizing maintenance cycles and minimizing downtime. Together, the use of these technologies not only ensures safety and operational performance, but also helps plants maximize productivity and reduce the economic impact associated with coke formation. A proactive, preventive approach is key to long-term success in industrial furnace operation.

References

Own source