Cleaning up environmental disasters – oil tankers are a necessity, there are sustainable and innovative solutions – such as the sponge-that-absorbs-oil. For this reason, there is a need to find effective and sustainable solutions that allow to restore the affected ecosystems and mitigate the negative impacts generated by a spill.

The oil industry plays a fundamental role in the global economy and society, environmental disasters caused by oil spills represent one of the biggest challenges to face because the cleanup process can be long and difficult.

It is in this scenario, where innovation emerges, the sponge that absorbs oil takes center stage. These are technologies developed to minimize the impact caused by spills. Possessing unique hydrocarbon absorption, retention and recovery capabilities, they have proven to be a promising tool for spill response management.

Absorbent materials provide a useful resource in response to an oil spill, allowing it to be recovered in situations that are not suitable for other techniques, marking a milestone in the restoration of environmental disasters and in the preservation of the ecosystem.

The number of oil spills has decreased dramatically in recent decades, but they still happen and often affect marine and terrestrial wildlife. So what can be done to address them?

Without a doubt, one of the oil cleaning technologies that has gained the most ground over time are those that include “absorbent materials or biosponges.”

Oil absorbents comprise a wide range of organic, inorganic and synthetic products designed to recover oil in preference to water. Its composition and configuration depends on the material used and its intended application in answer 1 .

Although widely used in response to spills, absorbents must be used with caution to minimize inappropriate and excessive use that can present difficulties associated with secondary contamination, recovery, storage, and disposal of this contaminated material 1 .

Sorbents are materials that absorb, adsorb, or both. Adsorption and absorption mean very different things. Therefore, it is necessary to understand their distinction 2 :

Absorption: is the process by which a substance is soaked in an absorbent material. When an absorbent is wetted in oil, its size increases by at least 70%.

Adsorption: involves individual molecules, atoms, or ions adhering to the surface of an adsorbent material. An adsorbent collects a layer of oil on its surface without expanding beyond 50%.

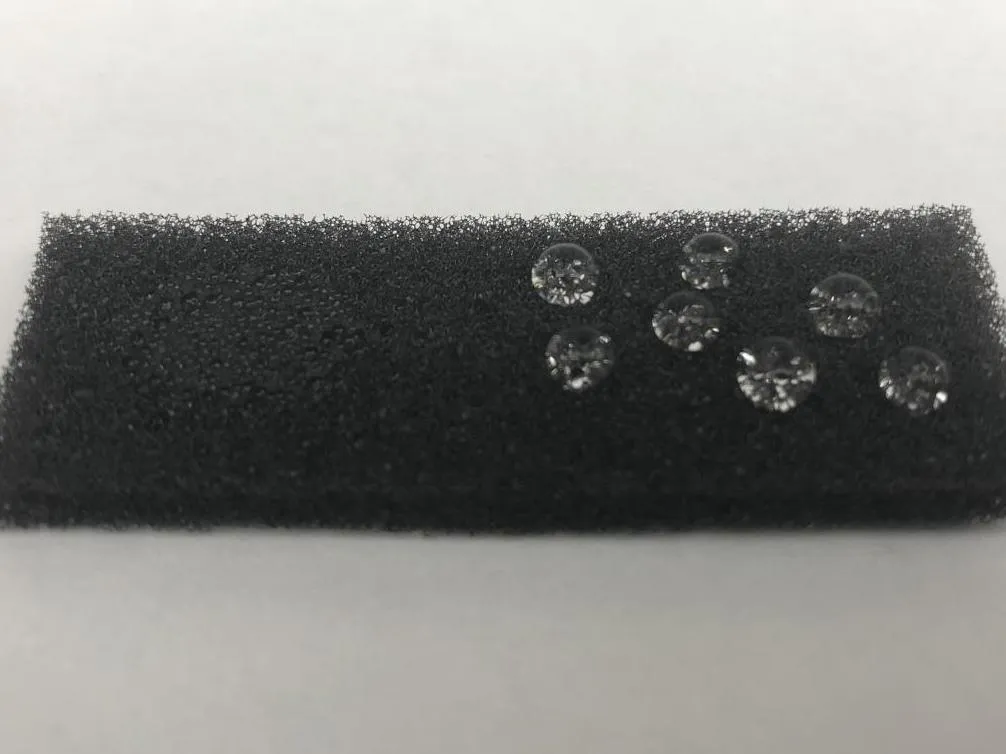

There are also two other characteristics to take into account, which are important for oil absorbents: such as oleophilic, which have the ability to attract oil, and hydrophobic, which means repelling water. Combined, all of these properties create effective absorbents for spill cleanup.

The sponge that absorbs oil

The Deepwater Horizon explosion in 2010, when millions of barrels of oil spilled into the Gulf of Mexico, led many scientists to rethink cleanup technologies 3 , including items made from absorbent materials.

The search for effective solutions to deal with oil spills has led to the development of timely technologies such as the oil absorbing sponge . This accessory has proven to be highly efficient and has advantages over other cleanup methods, even though the size and location of a spill are critical factors in its application.

The oil adsorbing sponges are based on unique and sophisticated technology. Manufactured with special highly absorbent materials, they have the ability to selectively attract and retain hydrocarbons, separating them from the surrounding water. Its porous structures act as a smart trap, trapping the spilled oil and minimizing its dispersion in the environment.

One of the main advantages of this technology is its high performance in oil recovery. Its selective adsorption capacity minimizes the capture of water and other contaminants, resulting in more efficient removal. Its application does not require highly specialized personnel, which speeds up the cleaning processes and minimizes the associated risks.

Another outstanding aspect of these accessories is their reusability. After use, it can undergo regeneration processes, where the adsorbed oil is recovered and recycled. This feature not only reduces costs associated with waste disposal, but also contributes to sustainability and care for the environment.

Obstacles and challenges in implementing the sponge

Despite the benefits and promising potential of oil-absorbent materials, their large-scale implementation in the petroleum industry faces certain challenges that need to be addressed to maximize their effectiveness and reach.

Costs and Scalability of Large-Scale Production: Typically complex to manufacture, the mass production of absorbent sponges required to deal with large spills can be challenging in terms of cost and scalability. It is necessary to optimize processes, search for affordable raw materials and develop technologies that allow profitable mass production.

Environmental Impact Assessment: Prior to implementation, a comprehensive environmental impact assessment is required to understand the potential side effects of using these absorbents. These evaluations must address aspects such as the interaction with marine life, the biodegradability of the materials, the possible impacts on the surrounding ecosystems and the problems for their subsequent collection.

In addition, it is important to take into account that there are certain limitations in its application, particularly in relation to the properties of the spilled oil, such as its viscosity. On the other hand, recovering and disposing of these oiled materials requires a lot of energy and there is always a risk that oil-contaminated waste will be lost at sea.

Research Papers on Absorbent Oil Sponges

Research centers and universities are constantly exploring different materials in order to develop more efficient absorbent sponges. These studies involve tests that have shown successful results.

High-Performance Solar-Assisted Cleanup of Viscous Oil Spills Using an Ink-Modified Plant Fiber Sponge 4 : “Journal of Hazardous Materials” Magazine. The research proposes an innovative approach that combines solar energy and the use of an ink-treated plant fiber sponge to improve the cleanup efficiency of viscous oil spills. The ink used in the sponge acts as a photothermal agent, allowing the absorption of solar energy and localized heating. The localized heating generated by the ink facilitates the reduction of the viscosity of the oil, which facilitates its absorption by the sponge.

A solar-heated Janus sponge with excellent buoyant stability for efficient heavy oil cleanup 5 : ” Materials & Design ” Magazine. The study shows that this sponge exhibits excellent buoyant stability in marine conditions with winds and waves, which guarantees its effectiveness in oil recovery in different environmental conditions. In addition, its ability to efficiently remove heavy oil stands out, making it a promising solution for spill cleanup. It could absorb viscous heavy oil stably by photothermal effect, with absorption capacity of 11.2g/g.

High-tech sustainable sponge 6 : A team of student-researchers at the University of Central Florida (UCF) is developing high-tech sponges capable of cleaning up ocean water after oil spills. They absorb oil while repelling water, and don’t leave behind any toxic byproducts. The collected oil is recycled for future use. The system uses the immersion drying method to place MoS2 throughout the porous substance to induce superhydrophobicity and superoleophilicity for the selective separation of water and oil in a sustainable manner.

Conclusion

The oil-absorbing sponge has proven effective in cases of spills in both marine and terrestrial environments. Its rapid response capacity, effective absorption, and versatility make it an invaluable tool in restoring affected ecosystems , protecting biodiversity, and contributing to the mitigation of oil disasters.

Following spill containment procedures and applying best practices helps minimize the damage caused by any spill incident. Specialized oil absorption sponges work through the physical absorption of oil into its porous structure. Its design and properties allow oil to be retained, providing an optimal solution to these emergencies.

The technologies responsible for designing absorbent sponges with the various raw materials available are ecological solutions of great contribution towards a sustainable future.

References

- https://www.uvm.edu/seagrant/sites/default/files/uploads/TIP8UseofSorbentMaterialsinOilSpillResponse.pdf

- https://www.absorbentsonline.com/spill-containment-blog/what-are-sorbents-for-oil-spills/

- https://www.cbc.ca/news/canada/calgary/super-sponge-university-calgary-oil-spill-mitigation-1.4950938

- htJin Yang, Peng Xu, Yilin Yao, Yong Li, Bing Shi, Xiaohua Jia, Haojie Song ; “Solar-assisted high-efficient cleanup of viscous crude oil spill using an ink-modified plant fiber sponge”; Journal of Hazardous Materials ; Volume 432 , 15 June 2022, 128740

- Jin Yang, Peng Xu, Yilin Yao, Yong Li, Bing Shi, Xiaohua Jia, Haojie Song ; “A solar-heated Janus sponge with excellent floating stability for efficient cleanup of heavy oil”; Materials & Design , Volume 195 , October 2020, 108979

- Vinayak P. Dravid, Vikas Nandwana, Stephanie M. Ribet, Roberto D. Reis, Yuyao Kuang, Yash More; “OHM Sponge: A Versatile, Efficient, and Ecofriendly Environmental Remediation Platform”