Table of Contents

- What is CFRP and what materials does it consist of?

- Advantages of CFRP in structural longevity

- Wet layup: Critical installation sequence

- CFRP strengthening: system and material selection

- Design and installation criteria for CFRP strengthening

- Failure modes and prevention strategies

- Reinforcement of concrete structures with CFRP

- Structural strengthening with CFRP in steel and ducts

- Structural retrofit according to ISO 24817

- System protection and quality assurance (QA/QC)

- Conclusions

- References

- Frequently Asked Questions (FAQs)

- Where is CFRP most effective: in concrete or metal?

- What are the advantages of CFRP over traditional steel reinforcement?

- What failures does CFRP prevent in structural strengthening?

- What standard regulates the use of CFRP in oil and gas pipelines?

- What is the main risk in a poorly executed CFRP installation?

The structural rehabilitation of industrial assets subject to fatigue, corrosion, or increased loads requires solutions that restore load-bearing capacity without introducing new sources of risk. In this context, CFRP (carbon fiber reinforced polymer) represents a highly efficient external reinforcement system capable of redistributing stresses, limiting crack propagation, and reducing stress concentrations without the need for welding or adding significant weight.

Its performance is conditioned by its specification as an integral system composed of substrate, adhesive, and laminate, where surface preparation, environmental control, and engineering design are decisive in ensuring the safe rehabilitation of assets in service and the reduction of operational downtime.

What is CFRP and what materials does it consist of?

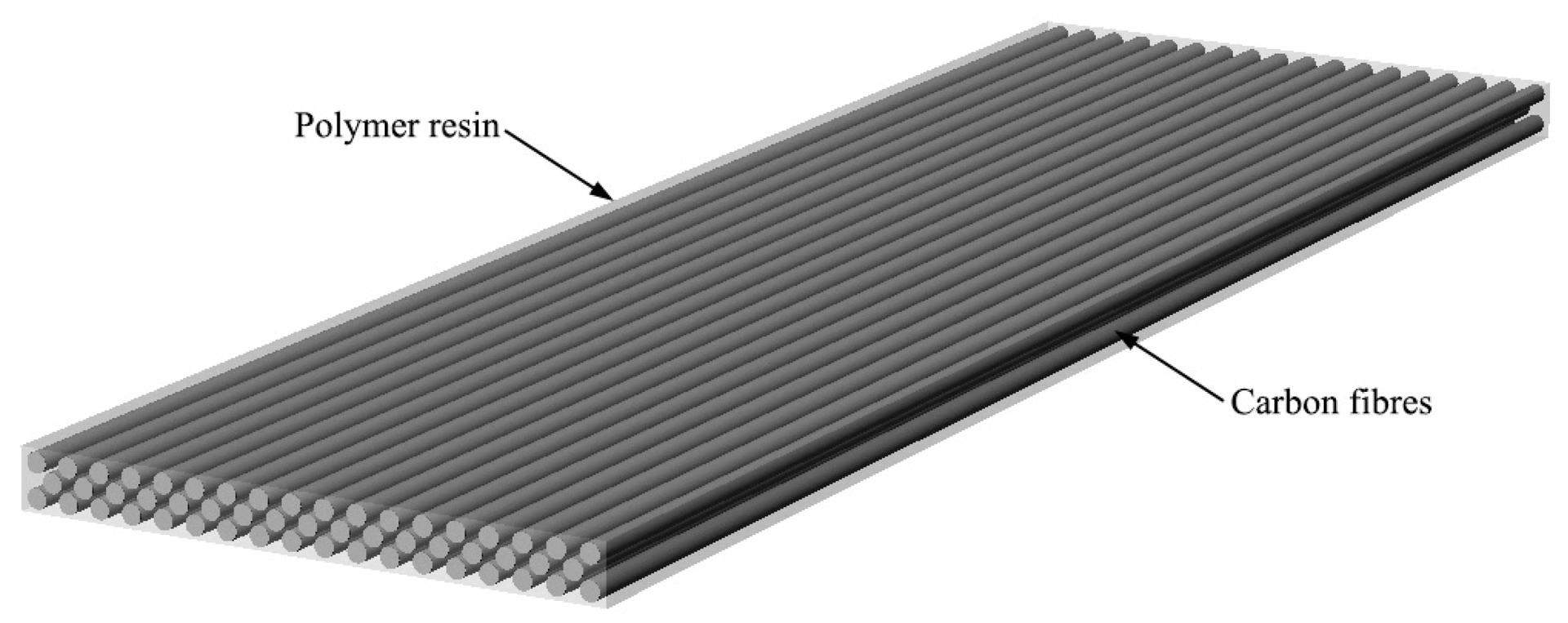

CFRP is an advanced composite material whose internal architecture is designed to maximize mechanical strength. It consists of two main elements that work in synergy:

- Reinforcement (carbon fiber): Thousands of carbon filaments provide rigidity and tensile strength. In structural engineering, unidirectional (UD) fabrics are mainly used, where 100% of the strength is concentrated on one axis, or multidirectional fabrics, depending on the load demand.

- Matrix (epoxy resin): This is the polymer that surrounds and protects the fibers. Its function is to transfer the stresses from the substrate (concrete or steel) to the fibers through adhesion. The quality of the matrix determines the chemical and thermal resistance and durability of the structural strengthening system.

Advantages of CFRP in structural longevity

The implementation of CFRP for structural retrofit offers clear technical benefits over traditional methods such as steel jacketing or concrete overlay, especially when the goal is to extend service life without operational penalties. Among its benefits are:

- Inertia against corrosion: Carbon is electrochemically inert, eliminating the maintenance cycle due to oxidation or corrosion in marine environments.

- Dead load optimization: Its high strength-to-weight ratio allows for increased capacity with millimeters of thickness, avoiding overloading foundations or altering the load balance on platforms and bridges.

- High specific strength: Allows beams or columns to be reinforced with minimal thicknesses (1.2 mm to 4 mm), maintaining the original geometry of the asset.

- Fatigue control: Slows the propagation of fatigue cracks in metal structures subjected to cyclic loads, extending the remaining useful life (RUL).

- Geometric versatility: Systems such as wet layup adapt to complex configurations (elbows, nodes, transitions) that are not feasible for rigid metal reinforcements.

Wet layup: Critical installation sequence

The innovation of CFRP lies not only in the material, but also in the disciplined execution of the wet layup protocol. To ensure the integrity of the system, the process must strictly follow these steps:

- Substrate preparation: This involves more than just cleaning; an ICRI CSP 3 anchor profile must be achieved through controlled abrasion and rounded edges (minimum radius 20–25 mm) to avoid stress concentrations that could fracture the fiber.

- Priming: Application of a low-viscosity resin that penetrates the pores of the concrete or the micro-reliefs of the steel, creating an effective stress transfer zone.

- Saturation and application: The fibers must be impregnated evenly. Both dry areas and excess resin weaken the system, reducing structural efficiency.

- Consolidation and overlaps: A grooved roller is used to remove trapped air (prevention of delamination). Overlaps must be at least 150–200 mm to ensure structural continuity.

CFRP strengthening: system and material selection

The system selection must directly address the failure mode to be controlled. Prefabricated laminates are used when high directional efficiency and additional stiffness are required on flat surfaces, such as in the flexural reinforcement of beams and slabs.

In contrast, wet-laid layers are dominant in configurations that require structural continuity, such as the confinement of columns or components with pronounced curvatures.

In metallic assets and pipelines, the selection is even more critical due to the electrical conductivity of carbon. To preventgalvanic corrosion, the design must incorporate a dielectric barrier or insulating primer, preventing moisture from closing the electrochemical circuit between the CFRP and the steel.

Design and installation criteria for CFRP strengthening

CFRP generally does not fail due to a lack of intrinsic strength; the most common cause is inefficient transfer of forces at the interface. A professional design should focus on preventing premature debonding.

Substrate control: CSP and pull-off strength: Adhesion depends entirely on surface condition. ICRI CSP profiles close to CSP 3 should be specified through mechanical preparation. Pull-off testing is mandatory to verify that failure occurs preferably at the substrate and not at the adhesive interface, confirming an effective anchorage zone.

Climate window and dew point: Condensation control is critical. Before and during application, the surface temperature must be kept at least 3°C (5°F) above the dew point. A microscopic film of moisture can compromise epoxy polymerization and lead to delamination in the medium term.

Failure modes and prevention strategies

Adding more material does not compensate for poor engineering details:

- Debonding: Prevent by controlling the weather window and avoiding invisible condensation.

- Delamination: Mitigate with uniform saturation and anchoring details in areas of stress concentration.

- UV degradation: Epoxy resin is sensitive to solar radiation; it is mandatory to apply a final protective coating as a sacrificial layer.

Reinforcement of concrete structures with CFRP

In civil infrastructure, CFRP acts as external reinforcement, providing traction and confinement. Under ACI 440.2R, the design limits the effective deformation of the composite to prevent premature detachment. In columns, the carbon fiber wrap generates a triaxial stress state that increases ductility and load-bearing capacity, which is key in structural retrofit and seismic rehabilitation where space is limited.

To understand the precision required in composite engineering, the following video from Structural Reinforcement Solutions shows the professional sequence of installing CFRP laminates and fabrics, highlighting the importance of intimate contact between the substrate and the reinforcement.

Carbon Fiber Strengthening Systems for concrete infrastructure.

Structural strengthening with CFRP in steel and ducts

In steel, CFRP competes with welded plates, with the advantage of eliminating heat-affected zones (HAZ). The key is surface preparation (white metal) and edge sealing. In preventive repairs, substantial improvements in stiffness and remaining service life are achieved; when corrosion has progressed excessively, effectiveness is reduced.

Galvanic compatibility and dielectric barriers

Carbon and steel form a galvanic couple; if electrolyte (moisture/salts) is present, corrosion can be accelerated at the edges of the laminate. To mitigate this damage process, electrically insulating dielectric barriers are used without compromising structural transfer.

These layers are usually implemented using insulating primers, adhesives with dielectric fillers, or non-conductive intermediate layers, and require perimeter sealing to prevent electrolyte ingress and under-edge corrosion.

Areas of application for asset recovery with CFRP

The versatility of the fiber-matrix composite system allows it to be engineered to address specific damage mechanisms in a wide range of industrial and civil infrastructure. Its adoption is particularly relevant in assets where downtime is critical and traditional interventions involve high operational risks. The main areas of application include:

- Storage tanks (API 650 / API 653): Restoration of structural integrity in shells affected by internal or external corrosion thinning, as well as structural sealing of bottoms with localized containment loss. CFRP allows intervention without hot work, reducing risks in classified areas and avoiding prolonged shutdowns.

- Piping and duct systems (ASME PCC-2 / ISO 24817): Reinforcement jackets designed to restore pressure retention capacity in lines with generalized corrosion, localized corrosion, erosion, or mechanical damage. In selected applications, the system allows for in-service repairs, maintaining operation without interrupting flow.

- Reinforced concrete structures (ACI 440): External reinforcement of beams, slabs, and walls deteriorated by corrosion of the reinforcing steel, as well as increased structural capacity in response to changes in use, overloads, or seismic code updates. Column wrapping with CFRP improves confinement, ductility, and seismic performance without increasing sections.

- Special industrial assets: Rehabilitation of industrial chimneys, silos, cooling towers, and offshore structures in splash zones, where CFRP’s resistance to aggressive environments surpasses conventional metal systems and significantly reduces maintenance cycles.

Structural retrofit according to ISO 24817

In oil and gas, the use of CFRP is governed by ISO 24817, which requires repairs to be treated as a traceable engineering action, defining thickness, number of layers, and installation criteria according to the type of damage. The standard ensures that reinforcement with composites represents a permanent solution, not a palliative one.

In addition, it establishes requirements for procedure qualification, environmental control, laminate inspection, and system documentation, including design limits, installation acceptance, and performance verification for continuous service.

System protection and quality assurance (QA/QC)

Composite repair requires complete system traceability to demonstrate compliance: substrate preparation, environmental control, material batches, installation and inspection records, and acceptance criteria.

Furthermore, the system does not end with resin curing. The polymer matrix must be protected against UV radiation, mechanical impact, and, where applicable, fire. Final protective coatings are not aesthetic; they are functional coatings that preserve the mechanical properties of CFRP against the operating environment. For project closure, the following must be documented:

- Environmental conditions during installation

- Traceability of materials

- Visual evidence of correct saturation

- Pull-off and Barcol hardness test results

Conclusions

CFRP allows you to move from reactive maintenance to an advanced mechanical integrity strategy. Its value is not limited to adding strength, but also to ensuring controlled stress transfer between substrate, adhesive, and laminate, under disciplined execution.

When surface preparation is traceable, dew point control is rigorous, and the selection of fibers, resins, and dielectric barriers is compatible with the asset, performance becomes predictable. With frameworks such as ISO 24817 and ACI 440, structural strengthening with composites is consolidating itself as an efficient solution for extending service life and sustaining reliability in critical infrastructure.

References

- Carbon Fibre Reinforced Polymer, Sciencedirect. https://www.sciencedirect.com/topics/engineering/carbon-fibre-reinforced-polymer

- https://en.wikipedia.org/wiki/Carbon-fiber_reinforced_polymer

Frequently Asked Questions (FAQs)

Where is CFRP most effective: in concrete or metal?

It is highly effective in both, but for different purposes. In concrete, it is the standard solution for confinement and bending without increasing sections; in metal, it is a cutting-edge option for mitigating fatigue and restoring structural integrity without the thermal risks of welding.

What are the advantages of CFRP over traditional steel reinforcement?

CFRP does not introduce significant dead load, does not generate heat-affected zones (HAZ), and offers high specific strength, ideal for rehabilitation without modifying geometry or interfering with operation.

What failures does CFRP prevent in structural strengthening?

It mitigates flexural cracking, shear failure, loss of confinement, and fatigue cracking. In pipelines, it restores pressure integrity against external and internal corrosion within the system design criteria.

What standard regulates the use of CFRP in oil and gas pipelines?

ISO 24817 establishes design, installation, and quality assurance criteria for composite repairs in the energy industry, including traceability and procedure qualification requirements.

What is the main risk in a poorly executed CFRP installation?

The most common failure is premature debonding due to poor surface preparation or inadequate dew point control during installation, which drastically reduces stress transfer at the interface.