Table of Contents

- VCI Technology: Operation and application

- Corrosion at the bottom of storage tanks

- API response: Introduction of API TR 655

- Combined VCI and Cathodic Protection (CP)

- Operational criteria for the application of VCI inhibitors in tanks

- Expected benefits and practical limits of VCI

- VCI implementation and monitoring according to API TR 655

- Conclusions

- References

- Frequently Asked Questions (FAQs) about API TR 655 and VCI

The mechanical integrity of atmospheric storage tanks is one of the critical parameters of operational safety and asset management systems in the energy industry. Corrosion of the tank bottom, particularly on the soil-side, is a recurrent phenomenon that affects the structural lifetime, favors the loss of steel thickness and can lead to leaks or environmental impacts.

The API TR 655 technical publication (1st edition, 2021) establishes guidelines to mitigate this type of deterioration through the use of vapor phase corrosion inhibitors (VCI). This technology integrates with Cathodic Protection (CP) systems and expands corrosion control strategies aimed at maintaining tank reliability and operational continuity.

VCI Technology: Operation and application

VCI technology represents a gas-phase mitigation tool that provides localized chemical protection in confined spaces below the bottom of the tank, where the CP stream may not reach.

Action mechanism of a vapor-phase corrosion inhibitor

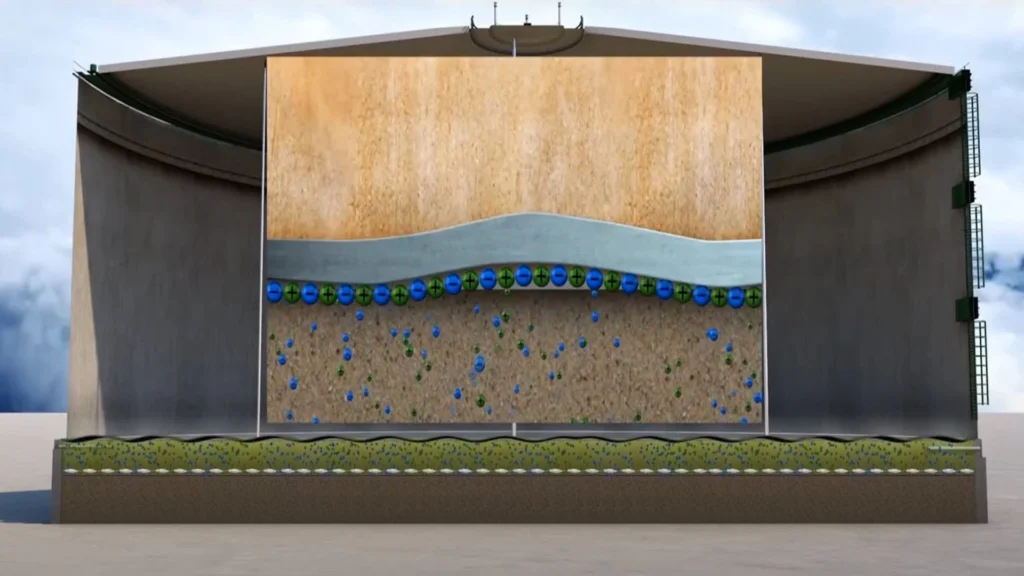

A Volatile Corrosion Inhibitor (VCI) is a chemical compound, solid or liquid, that volatilizes or sublimes at atmospheric pressure, releasing active molecules that diffuse into the space below the bottom of the tank. These molecules, which are polar in nature, adsorb on the steel, forming a protective molecular layer that interrupts the electrochemical reactions between moisture, oxygen and corrosive ions.

The effectiveness of VCIs is evaluated according to recognized methodologies, such as NACE/AMPP TM0208 (Vapor Inhibiting Ability), in addition to corrosion coupons, ER/LPR probes and correlations with API 653 inspections.

Corrosion at the bottom of storage tanks

Hydrocarbon and chemical tanks operate on sand, gravel or concrete foundations where moisture and oxygen are concentrated, creating ideal conditions for under-tank corrosion. This degradation, which occurs on the external face of the bottom, is a problem that is difficult to access and monitor, and can progress in a localized manner.

Soil-side corrosion mechanisms

Soil-side corrosion is caused by the presence of moisture, oxygen and dissolved salts trapped under the bottom of the tank. This moisture, often combined with differences in soil aeration (differential concentration cells), creates the perfect electrolytic environment for galvanic cells to develop.

Cathodic protection has historically been the first line of defense; however, its effectiveness can be compromised under certain conditions, such as:

- Shielded areas: dielectric materials or high resistivity soils that prevent or limit current flow.

- Severe localized corrosion: areas where the corrosion potential is so high that the CP alone fails to completely polarize the metal surface.

This reality has prompted the industry to seek and standardize complementary solutions that offer an additional and more localized layer of protection.

API response: Introduction of API TR 655

API TR 655 (Technical Report on Vapor Corrosion Inhibitors for Protection of Tank Bottoms) is a non-binding technical report that provides guidance to owners and operators on the use of VCI to protect the bottom of storage tanks on the ground side. This document defines when their use may be appropriate, how to verify their performance and recommends their integration with existing cathodic protection.

Unlike a mandatory standard, a Technical Report brings together field experience, best practices and engineering criteria to support informed technical decisions.

Scope and approach

API TR 655 establishes guidelines for the application, monitoring and maintenance of vapor-phase corrosion inhibitors on the external side of the bottom of storage tanks, where its contents guide engineers in:

- Chemical fundamentals of VCI and its mode of action.

- Selection criteria, according to tank type and soil condition.

- Application methods, both in new and existing tanks.

- Monitoring and performance verification practices.

The document emphasizes that VCI technology should be integrated into an overall corrosion mitigation strategy, and not be interpreted as a replacement for CP.

Relationship to other API references

This document complements key inspection and protection documents:

- API RP 651: Cathodic protection in aboveground tanks.

- API RP 575: Inspection of storage tanks.

- API 653: Requirements for inspection, repair and reconstruction.

Together, these publications establish a coherent framework that allows VCI to be integrated into existing mechanical integrity programs, from design to predictive maintenance.

Combined VCI and Cathodic Protection (CP)

The most solid approach, supported by API TR 655, is the combination of VCI and CP, taking advantage of the synergy between electrical and chemical protection.

| Technology | Primary mechanism | Coverage | Key benefit |

|---|---|---|---|

| Cathodic Protection | Imposed current stopping anodic reactions | Wide, depending on the electrolyte | Long-term macro-area control |

| VCI Inhibitors | Forms a passive molecular barrier | Localized and interstitial | Point corrosion mitigation and shielded areas |

The VCI + CP combination provides redundancy and improves coverage in high resistivity soils, marine environments or during shutdowns and power outages, provided there is a semi-confined space and adequate perimeter sealing.

Operational criteria for the application of VCI inhibitors in tanks

The use of VCI under the bottom of the tank is recommended in the following cases, according to the practice gathered in the technical report and operational experiences:

- New project or reconstruction: install the VCI system from the design phase.

- Major maintenance or raising: apply or recharge VCI during bottom repair.

- Insufficient cathodic protection: tanks with shielded areas or high resistivity soils.

- Aggressive conditions: marine environments, persistent moisture or chloride contamination.

- Need for continuity: maintain chemical protection during hibernation or power outages.

- In-service recharge: when foundation design permits, by means of ports or diffusers.

Expected benefits and practical limits of VCI

Benefits

- Complementary coverage: protects areas with low electrical contact or shielding effect.

- Adaptable installation: possible on new or existing tanks without major structural interventions (depending on pad design).

- Proven compatibility: demonstrates chemical compatibility with CP and external bottom coatings.

- Operational support: provides protection during shutdowns, start-ups, hydrostatic testing and hibernation periods with inactive CP.

Limits and considerations

- Semi-confined space required: without proper sealing, vapor diffusion is reduced.

- Variable service life: effectiveness depends on inhibitor type and environment (re-injection based on observed performance).

- Moisture control: water ingress can dilute or wash away inhibitor.

- EHS verification: chemical compatibility and environmental safety should be evaluated according to data sheets.

VCI implementation and monitoring according to API TR 655

Preliminary evaluation

TR 655 states that, before applying a VCI system under the bottom of the tank, the following conditions should be evaluated:

- Type of foundation: determine whether the tank is located on compacted sand, gravel, grooved slab, dielectric liner, double bottom with sand bed, etc. This information conditions the diffusion of the inhibitor.

- Perimeter sealing and drainage: assess the integrity of the foundation ring, possible drainage ports and the presence of water or moisture that may reduce the effectiveness of the VCI vapor.

- Compatibility with existing systems: verify that the VCI inhibitor is compatible with the existing CP system, as well as with external metal bottom coatings.

- Operational and corrosion history: analyze thermal cycling, product operated, history of metal thickness under bottom, previous inspection reports to justify the need for the VCI.

- Existing monitoring capability: confirm that coupon infrastructure, ER/LPR probes, CP potentials and downstream measurement access are available or can be installed.

Inhibitor application and distribution

The TR 655 indicates several installation methods depending on the condition of the tank: new, in service or out of service.

- New tank or during rebottoming: VCI emitters, injection lines, or mixed inhibitor can be incorporated into the backfill bed prior to plate assembly.

- Existing tank in service or shutdown: installation using perforated ports in the foundation ring, injection of VCI in liquid or slurry form, or distribution of solid diffusers in interstitial spaces.

- Uniform distribution: the design should ensure that injection points or emitters are spaced so that the inhibitor covers the entire area of the bottom, including hard-to-reach areas.

- Saturation of the space below the bottom: the volume of filler material, vapor diffusion and its permanence directly influence long-term effectiveness.

- Replenishment and maintenance: TR 655 does not set a rigid reapplication interval; it recommends that the decision be based on corrosion trends, inhibitor performance data and system condition.

(Source: Piping and Corrosion Specialties)

Performance monitoring and evaluation

TR 655 recommends clear metrics to validate the success of the VCI system:

- Corrosion coupons and ER/LPR probes: buried under the bottom or distributed in the backfill bed, they allow to measure the actual corrosion rate and compare it with the baseline prior to VCI application.

- UT inspection and API 653 criteria: during shutdowns or scheduled events, thickness measurements, corrosion mapping and structural integrity verification can be performed.

- Comparison with CP data: when CP system exists, the synergy between CP and VCI should be analyzed, verifying that the inhibitor does not interfere negatively and that the protection is consistent.

- Monitoring result for replacement: if the data show increased corrosion, drop in protection potential, or loss of inhibitor, recharge or maintenance intervention should be scheduled.

The following video provides more information on the correct implementation and monitoring of VCI according to API TR 655.

Conclusions

API TR 655 consolidates best practices for applying vapor phase corrosion inhibitors (VCI) to the bottom of storage tanks on the ground side, providing a modern and complementary alternative to cathodic protection. Although its implementation is not mandatory, it is a valuable tool to extend service life, reduce failures and maintain mechanical integrity.

Integrating VCI + CP, with an API 653 and RP 575 compliant monitoring program, strengthens the structural reliability of the tanks and aligns with the asset management and industrial sustainability principles promoted by API and NACE/AMPP.

References

- https://www.cortecvci.com/whats_new/announcements/Above-Ground-Storage-Tanks.pdf

- www.zerustis.com/documents//brochures/ZIS_Tank%20Bottom%20Protection_Solution%20Brochure_v3%2007092025.pdf

Frequently Asked Questions (FAQs) about API TR 655 and VCI

What does API TR 655 cover?

Establishes guidelines for the application, verification and maintenance of vapor phase corrosion inhibitors (VCI) on the ground side of the bottom of tanks, complementing CP systems and API inspection practices.

Does API TR 655 require the use of VCI?

No. It is a non-binding technical report that provides guidance to owners and operators on when to apply VCI based on the design, soil condition and performance of the existing CP system.

Does VCI replace cathodic protection?

No. The VCI acts as a complementary chemical barrier in areas where CP flow is limited or irregular, providing additional protection and redundancy against soil-side corrosion.

When is it recommended to apply VCI in tanks?

During construction or repair, in tanks with poor CP, high resistivity soils or marine environments, and to maintain protection during hibernation or power outages.

How is a VCI system installed under the bottom of the tank?

By liquid injection or solid diffusers under the bottom, distributing the inhibitor in the semi-confined space to form a protective adsorbed film on the steel.